114242 3-1 REV B

TORQUE

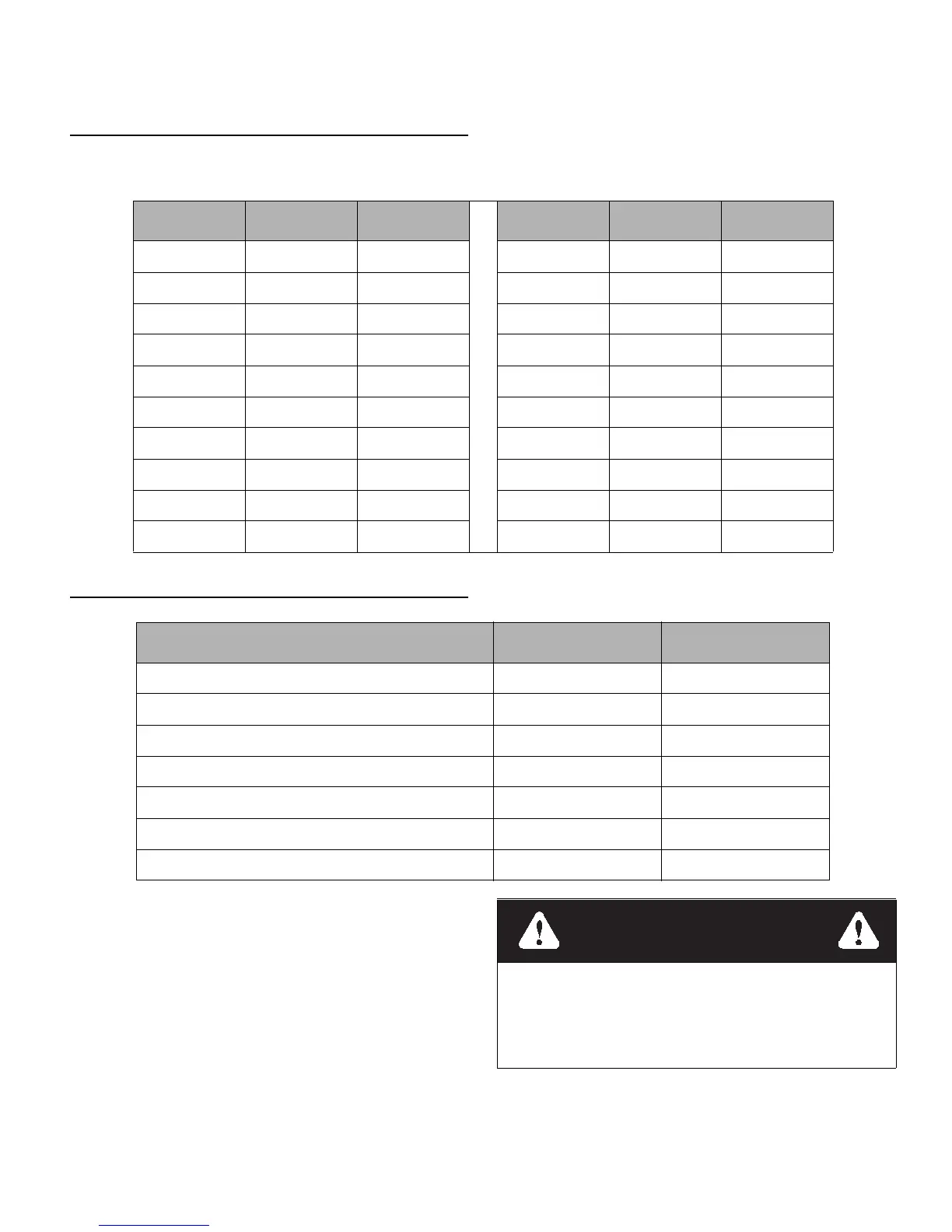

Standard Torques

The following chart lists the standard torque values for the threaded fasteners found in this manual. Torque all cap screws, nuts and

set screws to these values unless a different torque is shown in the Special Torques section.

Special Torques

NOTE:

1. Lug nuts only – It is recommended that these be checked

after the first 2 hours of operation and every 50 hours and

following removal for repair or replacement.

2. Engine torque values – Refer to the respective engine

owner’s manual.

3. If clutch mounting bolt is loosened or removed, do not

re-use. Replace with a new bolt. Use only hand tools to

install this fastener.

4. If using pin locknut, 250 ft.-lbs.

SIZE FT-LBS N-M SIZE FT-LBS N-M

#10 32.4 IN.-LBS. 3.6 M3 12 IN.-LBS. 1.3

.250 98.4 IN.-LBS. 11.1 M4 26.4 IN.-LBS. 3

.312 204 IN.-LBS. 23 M5 54 IN.-LBS. 6.1

.375 30 40 M6 92.4 IN.-LBS. 10.4

.438 48 65 M8 222 IN.-LBS. 25

.500 73 99 M10 37 50

.562 105 143 M12 64 87

.625 145 200 M14 103 140

.750 260 350 M16 160 215

.875 420 565 M20 320 435

SIZE FT-LBS N-M

Wheel (lug) nuts

1

70 95

Blade spindle bolt top 118 160

Blade spindle bolt bottom 118 160

Electric Clutch mounting bolt

3

45 – 48 61 – 65

Front wheel axle bolt 73 99

Transaxle hub nut

4

275 339

Transaxle pump pulley nut 45 – 55 61 – 74.6

Particular attention must be given to tightening the drive

wheel lug nuts and blade spindle bolts. Failure to cor-

rectly torque these items may result in the loss of a wheel

or blade, which can cause serious damage or personal

injury.

Loading...

Loading...