114242 5-1 REV B

ENGINE MAINTENANCE

General Engine Maintenance

Detailed instructions and recommendations for break-in and

regular maintenance are specified in the Engine Owner’s Man-

ual. Please refer to this manual for engine servicing, lubricating

oil levels with quality and viscosity recommendations, bolt

torques, etc. The engine warranty is backed by the manufacturer.

Special attention should be paid to applicable data which will

not be duplicated here.

Engine Oil and Filter

Check engine oil daily and after every 4 hours of operation.

Machine must be setting level when checking oil. Refer to

engine manual and maintenance schedule for oil recommenda-

tion and capacities.

Change the engine oil and filter after the first 5 hours of oper-

ation and per the engine manufacturer’s recommendations after

that. If mower is being operated in extremely dirty conditions,

then it is recommended oil be changed more frequently.

IMPORTANT: When removing the oil filter take precautions to

minimize oil spillage on the exhaust system.

Draining the engine oil:

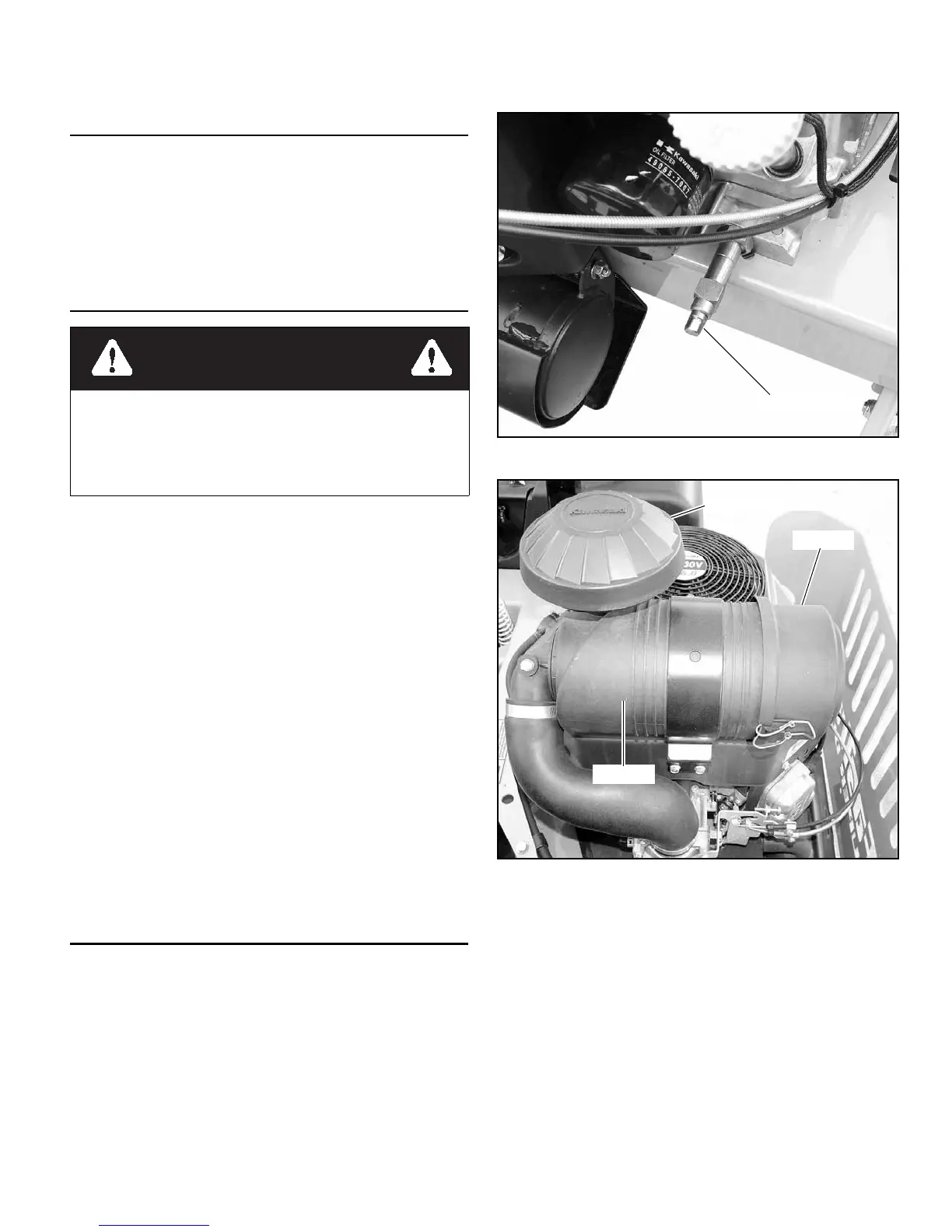

1. Locate the oil drain valve on the engine. Figure 5-1,

2. Position a suitable oil drain container under the machine

below the oil drain valve.

3. Twist the valve counterclockwise to open the valve.

Allow 10 minutes for engine oil to adequately drain.

4. After oil is drained, close the valve by twisting it

clockwise.

5. Once the valve is closed, clean up any spilled oil.

IMPORTANT: All oil drips or spills must be cleaned off

of the exhaust system before operating the machine.

Engine Air Filter

Perform engine air filter maintenance per the Maintenance

Schedule shown elsewhere in this manual.

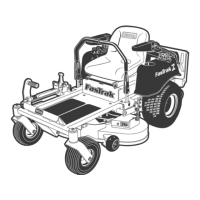

A specially designed dry filter is standard equipment on these

mowers and supplies clean combustion air to the engine. Figure

5-2

These mowers are equipped with a safety filter. The filter ele-

ment slides over the safety filter. Figure 5-3

The safety filter does not require servicing unless it becomes

contaminated with dirt or moisture.

Recommended service procedure

1. Release clamps and remove element. Clean the canister

with a damp cloth.

2. Before installing a new element, inspect it by placing a

bright light inside and rotating the element slowly,

looking for any holes or tears in the paper. Also check

gaskets for cuts or tears. Do not attempt to use a damaged

element which will allow abrasive particles to enter the

engine.

3. Reinstall the dust cap. Make sure it seals all the way

around the air cleaner body, then tighten the clamps.

Figure 5-2

4. Check all fittings and clamps periodically for tightness

and inspect hoses for holes or cracks.

5. Periodically check the intake hose for signs of ingested

dust. Locate and repair the source of ingested dirt.

6. Never operate the machine without an air filter installed.

If the engine has been running and is up to operating tem-

perature, allow the engine to cool before changing the oil.

Engine and engine oil will be very hot, so be very careful

when changing oil and wear the appropriate protective

gear to avoid being burned or exposed to engine oil.

Figure 5-1

Figure 5-2

Pre-cleaner

Canister

Dust cap

Loading...

Loading...