MAINTENANCE

HySpeed HT2000 Instruction Manual 8-27

20

Check Pump, Motor and Solenoid Valve (V1)

1. If coolant is not flowing, check to see if motor and valve V1 are getting 240VAC. Note: The 240VAC relay

(CR3) on PCB1 will not close until the first five (5) interlocks (STATUS) indicators are satisfied. (See

Startup Sequence flowchart)

2. If motor, pump and valve all seem to be functioning and the flow is not sufficient, replace the pump and

motor assembly.

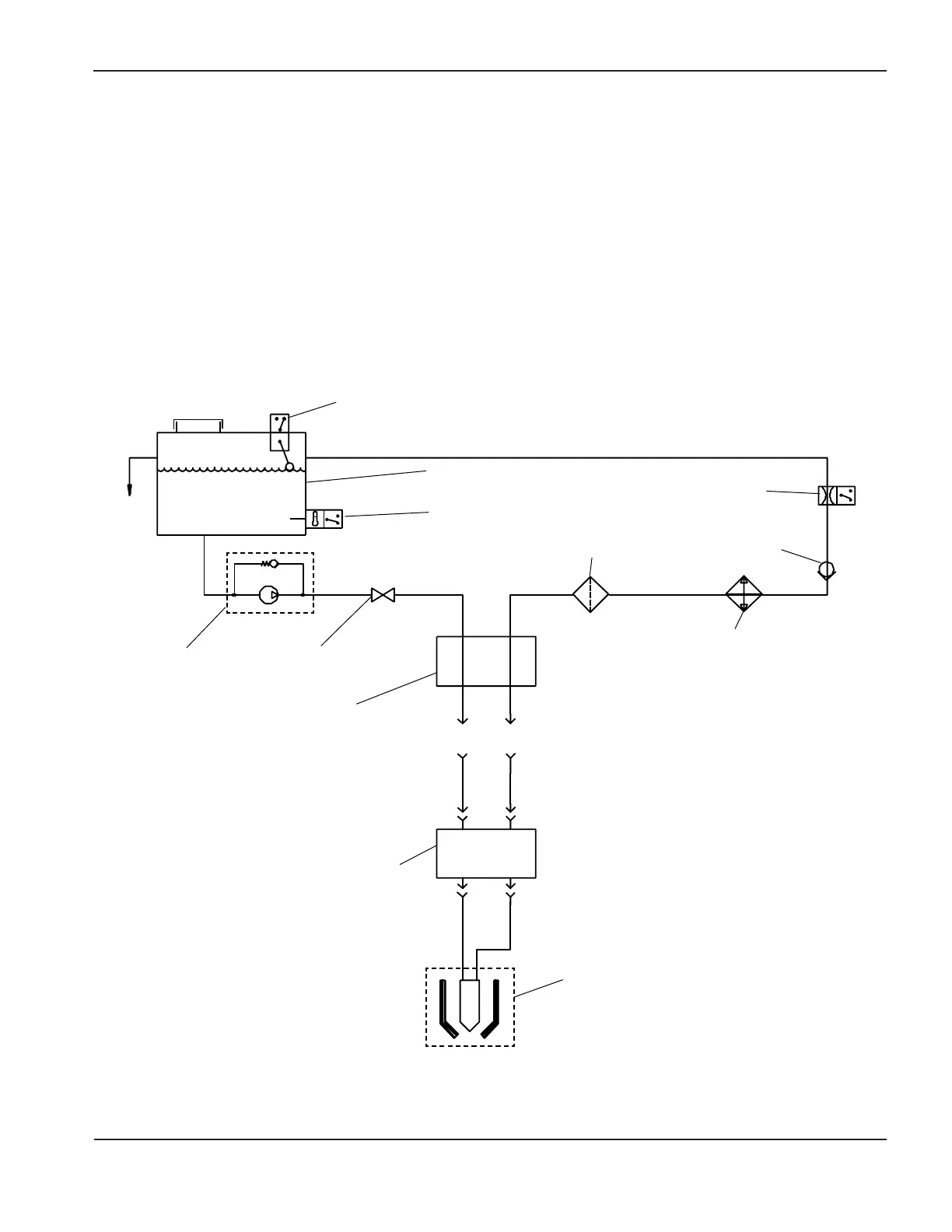

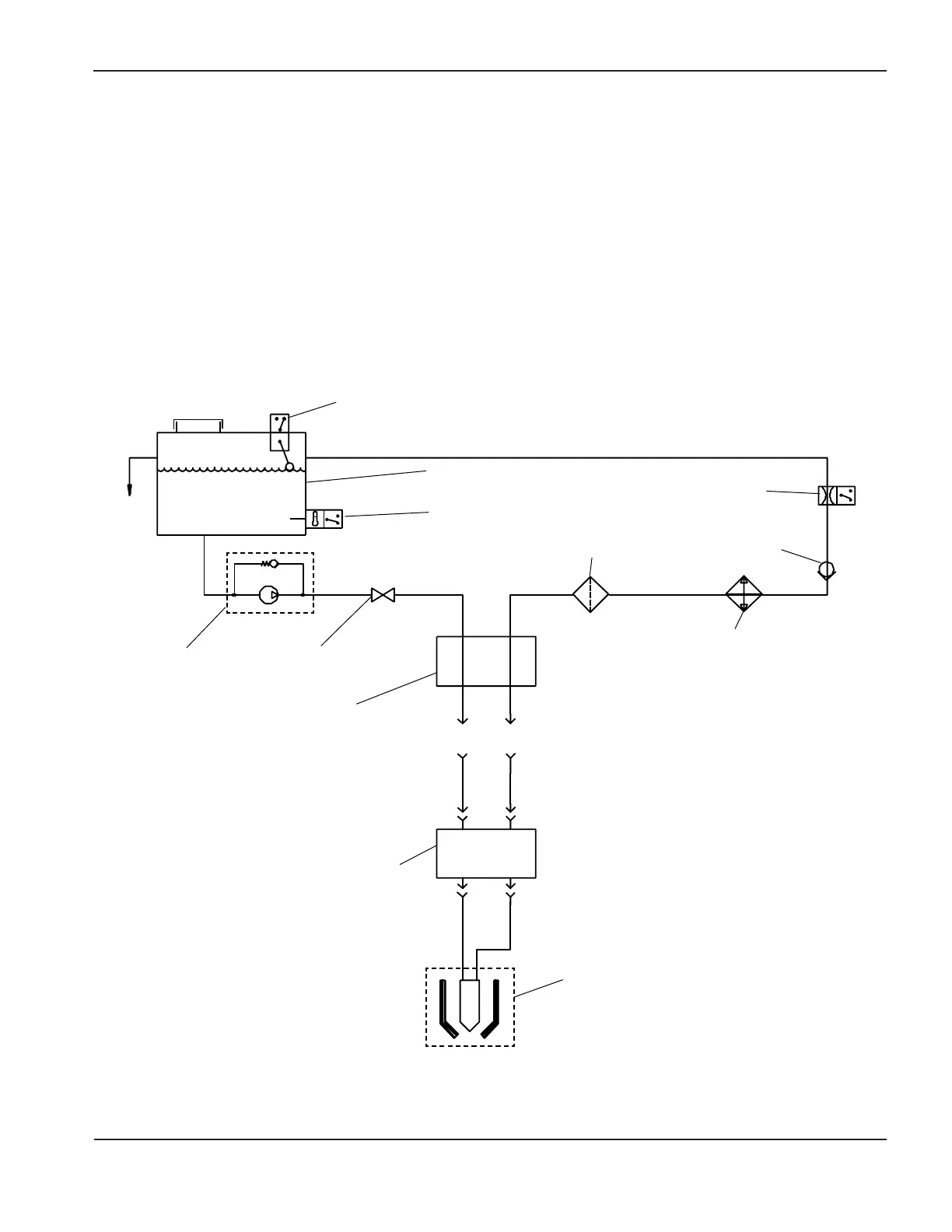

Figure 8-7 Plumbing Schematic of Power Supply Reservoir Assembly

with RHF Console and Torch

Cathode Block

(in back of

power supply)

Remote High Frequency

Console

Heat

Exchanger

Check

Valve

Flow Switch

FS1

Solenoid Valve

V1

Particulate

Filter

Coolant Reservoir

Float Switch

LS1

Temperature Switch

TS1

Torch

Pump with

Relief Valve

Loading...

Loading...