MAINTENANCE

3-14 powermax1000 Service Manual

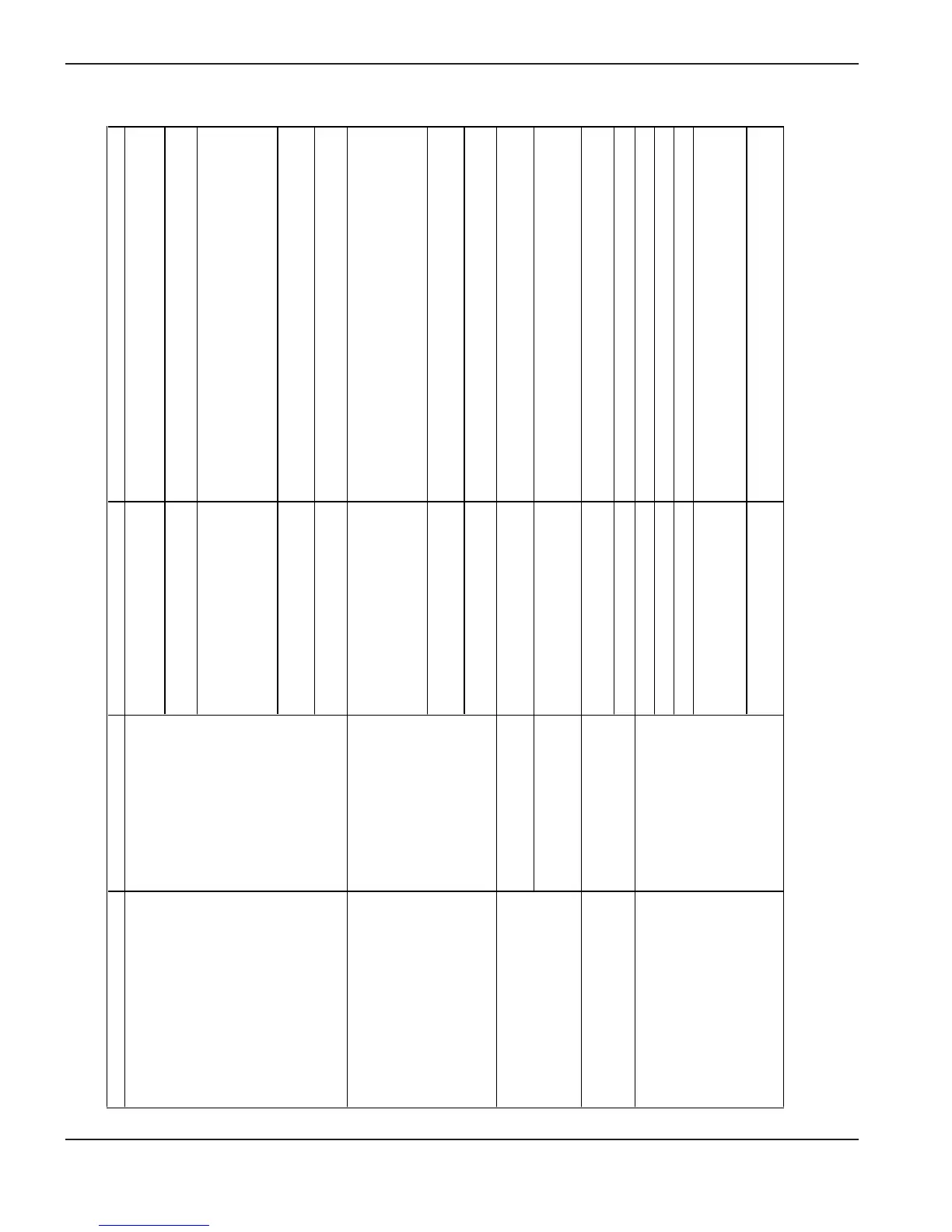

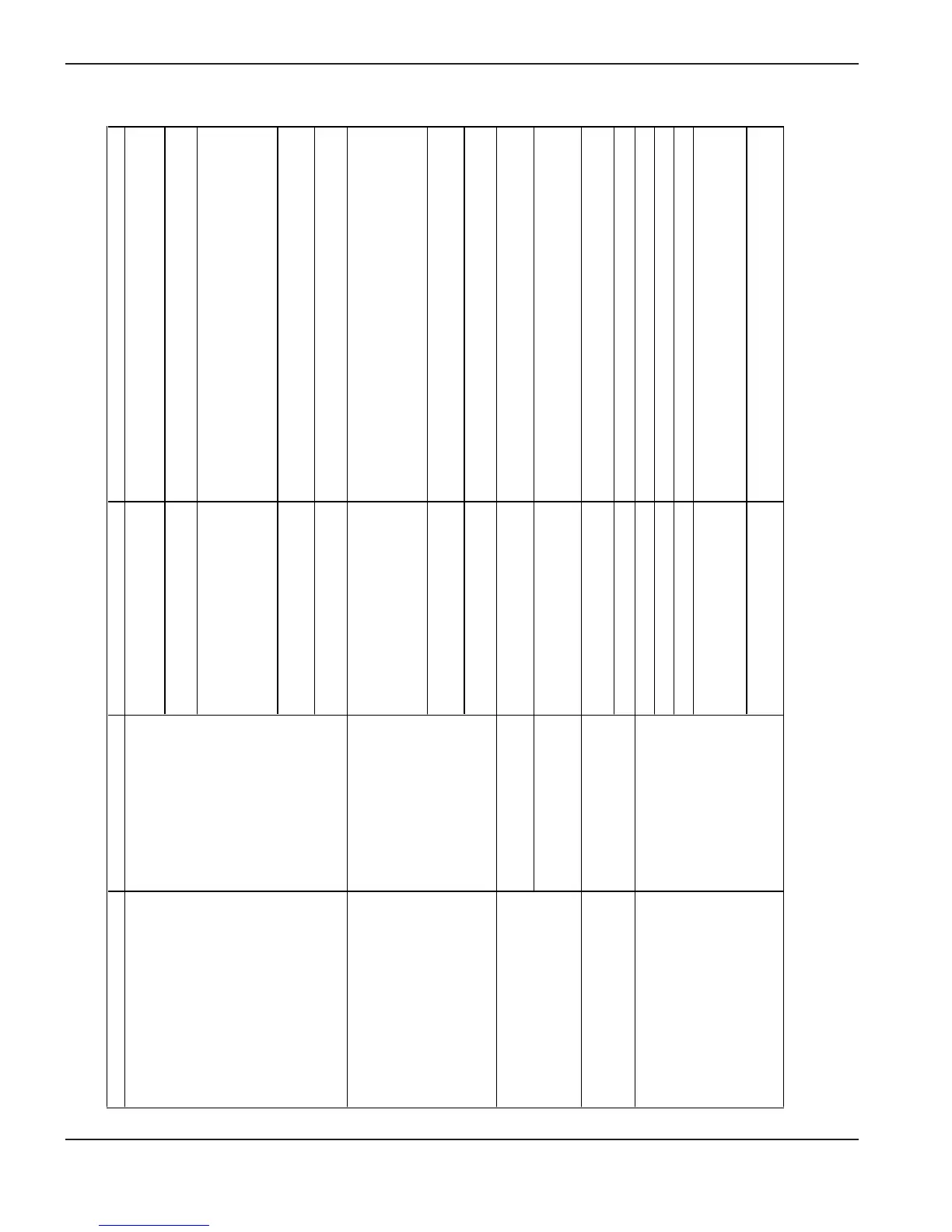

1

Problem This may mean Cause Solution

No voltage, improper voltage applied to

unit, defective power switch (S1), or

defective input diode.

Defective filter board (PCB1).

CE systems only: Measure the AC voltage at the CE filter. If no

voltage or low voltage, replace the filter board.

Defective power board (PCB2), fan, or

solenoid valve.

Disconnect J1 and J20 from power board and perform Test 6. If all

voltages are not present or if voltages are oscillating, replace the

power board. If the voltages are good, reconnect J1 and J20 one at a

time and perform Test 6. Replace the component that causes the

voltage to oscillate or drop.

Defective power board (PCB2) or IGBT

(Q6 or Q7).

Defective control board (PCB3). Replace the control board.

Defective power board (PCB2), fan, or

solenoid valve.

Disconnect J1 and J20 from power board and perform Test 6. If all

voltages are not present or if voltages are oscillating, replace the

power board. If the voltages are correct, reconnect J1 and J20 one at

a time and perform Test 6. Replace the component that causes the

voltage to oscillate or drop.

Defective power board (PCB2) or IGBT

(Q6 or Q7).

Defective control board (PCB3). Replace the control board.

System is in gas test mode.

The current adjustment knob is in the

gas test position.

Turn the knob clockwise until it is set at 20 amps or below.

Solenoid valve (V1) stuck open

or defective power board

(PCB2).

Faulty valve, power board (PCB2), or

control board (PCB3).

Voltage below proper operating limits,

or phase is lost.

Verify the incoming line voltage and the circuit size according to the

Operator Manual.

Faulty power board or control board. Perform Tests 5, 6, and 11.

No air supplied to unit. Connect air supply.

Dirty air filter element. Replace air filter element.

Restriction in air supply line. Replace the air supply line.

Air pressure setting below operating

requirements or incoming air pressure

is dropping when trying to fire the torch.

Turn the current adjustment knob to gas test and set the pressure to

70 psi (4.8 bar) for cutting and 50 (3.4 bar) for gouging as required for

system operation. Verify the gas source is within the setup

specifications in Section 2.

Faulty pressure sensor assembly or

control board.

Insufficient voltage to control

circuits, or shorted power

component.

Power On LED does not illuminate or

blinks when power switch is ON.

Insufficient air pressure.

Air pressure LED blinks yellow.

Improper line voltage or circuit

size.

Power On LED blinks, flashes, or

goes out while cutting.

Shorted power components.

Air flows from the torch at power-up

when neither the torch trigger nor

the start switch is activated.

Loading...

Loading...