Operation

XPR300 Instruction Manual 809480 229

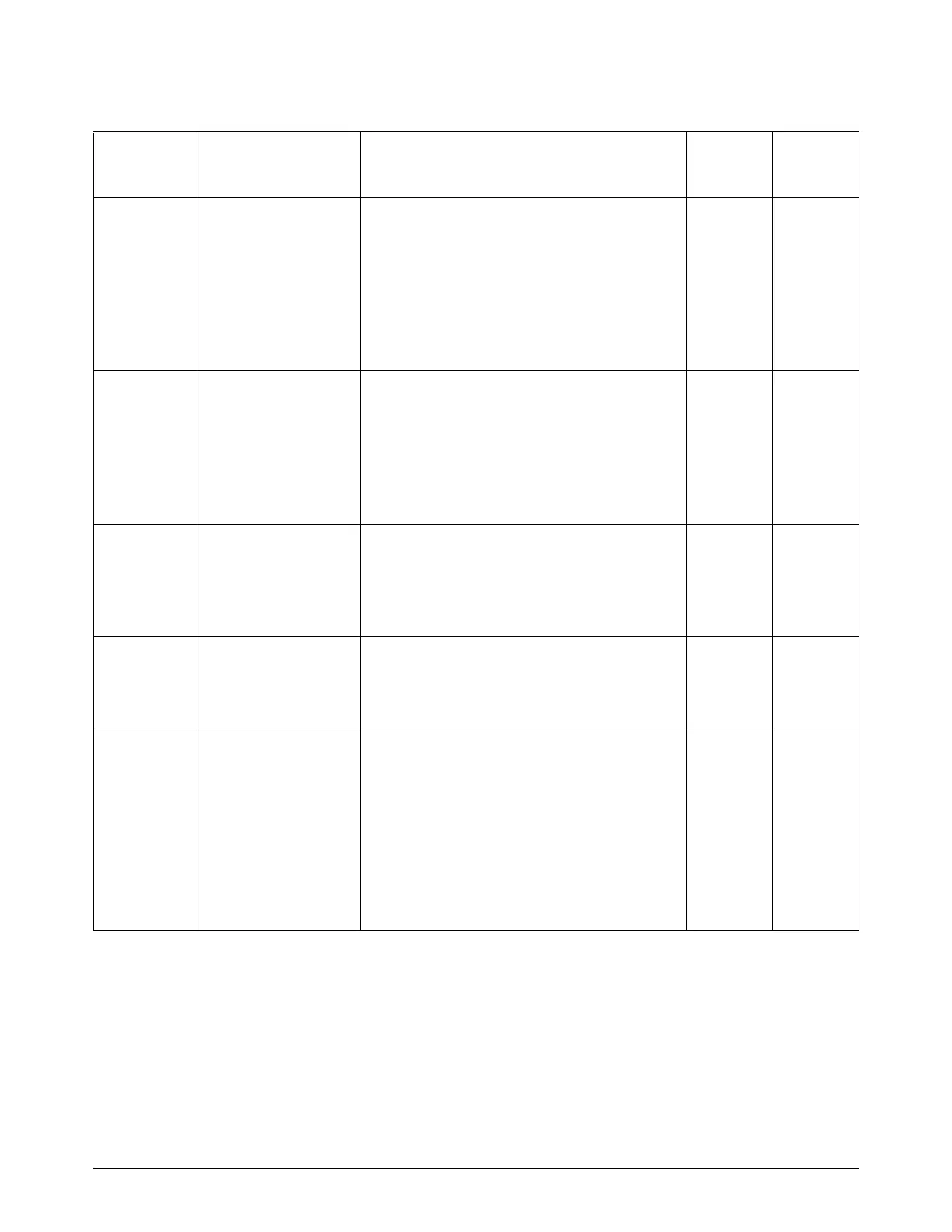

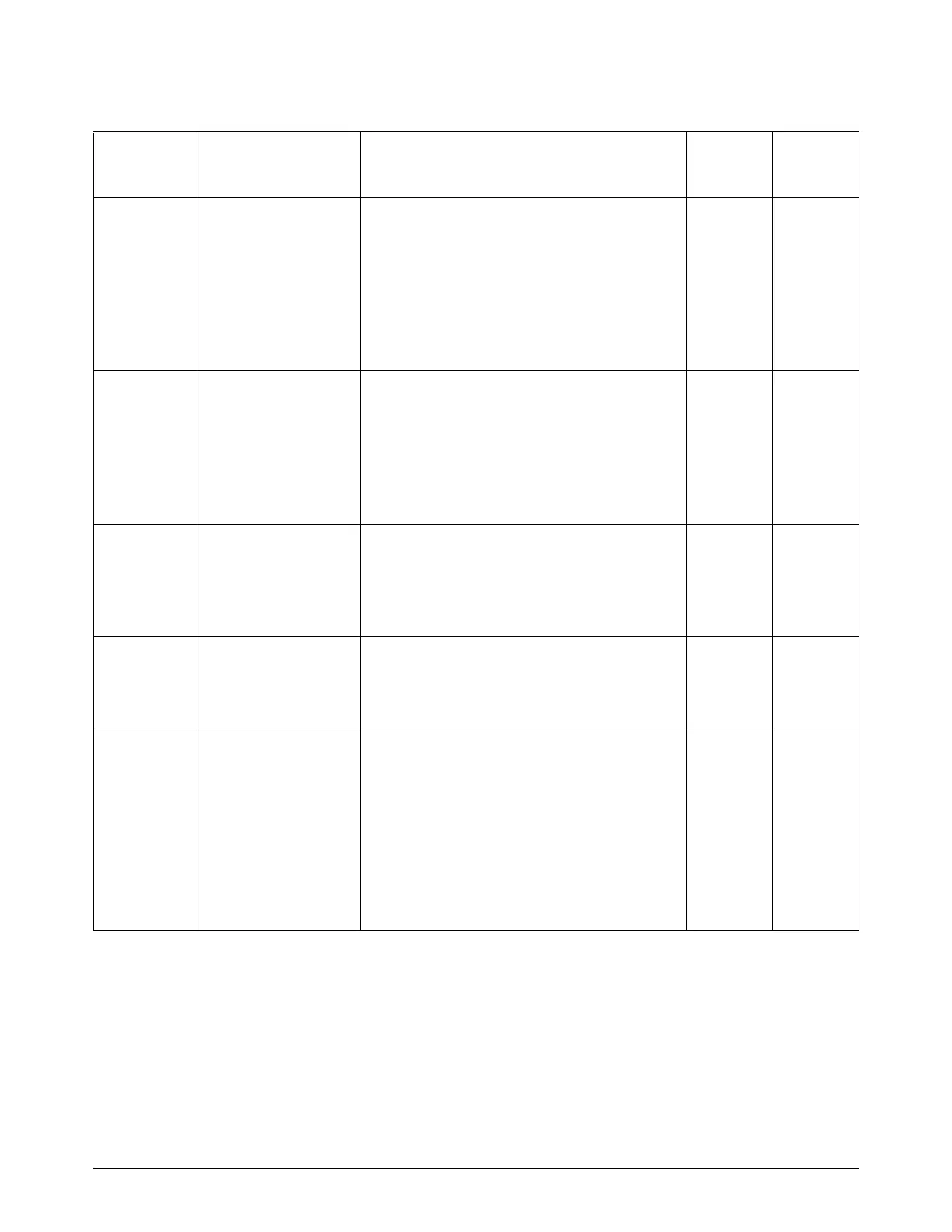

Table 31 – Process category options and expected quality-speed results for non-ferrous processes

In general, Hypertherm recommends dross-free processes. Non-ferrous

dross is very difficult to remove. Depending on the gas-connect console,

the XPR300 cutting system offers the following non-ferrous cutting

processes: Air/Air, N

2

/N

2

, N

2

/H

2

O, F5/N

2

and mixed-fuel gas/N

2

. For

guidance about process selection, refer to Table 29 – Process

recommendations for cut quality, based on metal thickness and type on

page 220 and the XPR Cut Charts Instruction Manual (809830).

Process

category

number

Process category

condition

Category description Quality Speed

Category 1 Process Core

Thickness (PCT)

• Whenever possible, select Category 1 for

optimal edge quality and speed, with

minimal dross.

• The process is optimized for this thickness.

• Expect cut speeds that range from

1,016 mm/min – 3,048 mm/min

(40 in/min – 120 in/min).

• Dross free, in most cases.

Very

good –

excellent

Very good

Category 2 Thicker than PCT • In most situations, you can expect square

cut edges with sharp top edges.

• Darker edge color is possible with stainless

steel.

• Expect cut speeds that are slower than

1,016 mm/min (40 in/min).

• Expect some dross.

Good –

very good

Lower

Category 3 Thinner than PCT • Select Category 3 when speed is more

important than edge quality.

• Expect cut speeds that are faster than

3,048 mm/min (120 in/min).

• Expect some dross.

Lower Higher

Category 4 Edge Start Only • Edge start is required.

• Darker edge color is possible with stainless

steel.

• Thick dross is likely.

Good Low

Category 5 Severance • This is the maximum thickness for these

processes.

• Edge start is required.

• Expect cut speeds that are slower than

250 mm/min (10 in/min).

• Cut-edge quality can be rough.

• Expect significant dross.

• Thick-metal cutting techniques can be

necessary.

Very low Very low

Loading...

Loading...