User Manual

25

7 Troubleshoong

All work on electrical parts or electrical connecons and the refrigerant circuit must

be carried out by qualied and authorised personnel.

Warning: Disconnect electrical power before performing any operaons on electrical

parts or on electrical connecons.

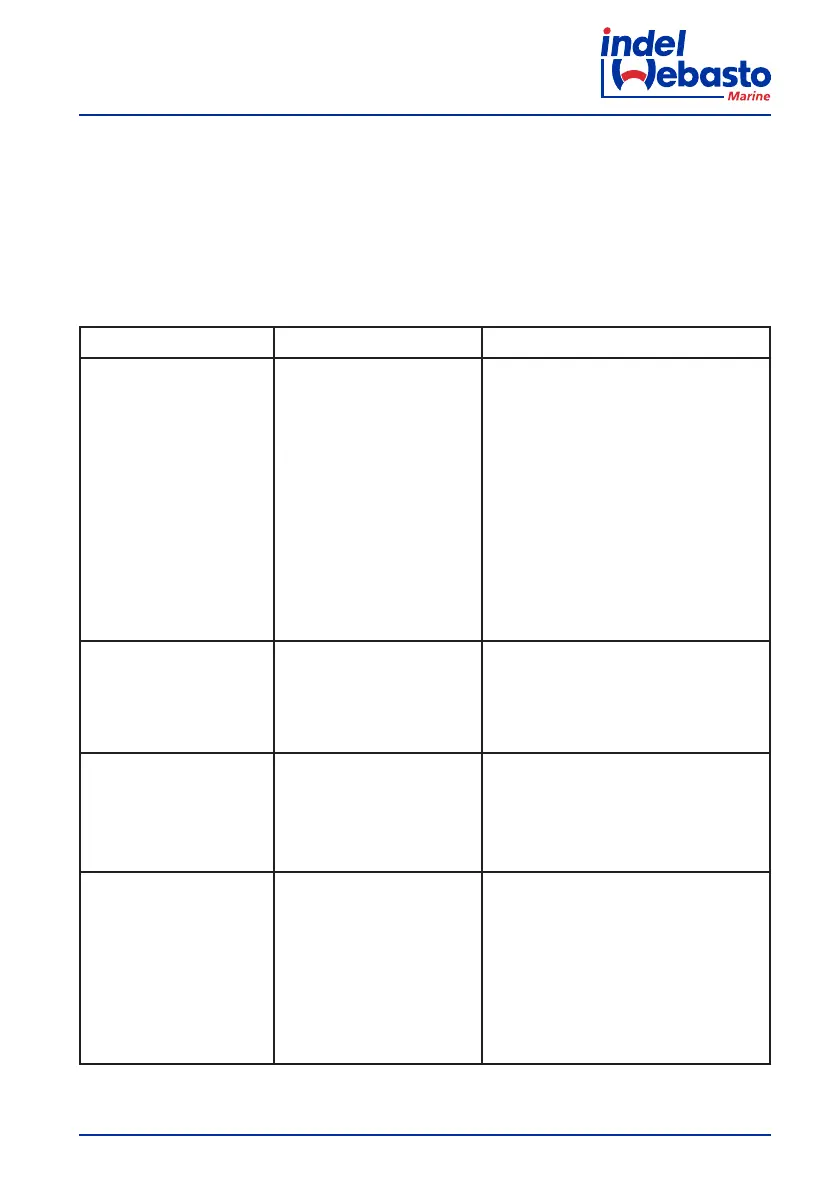

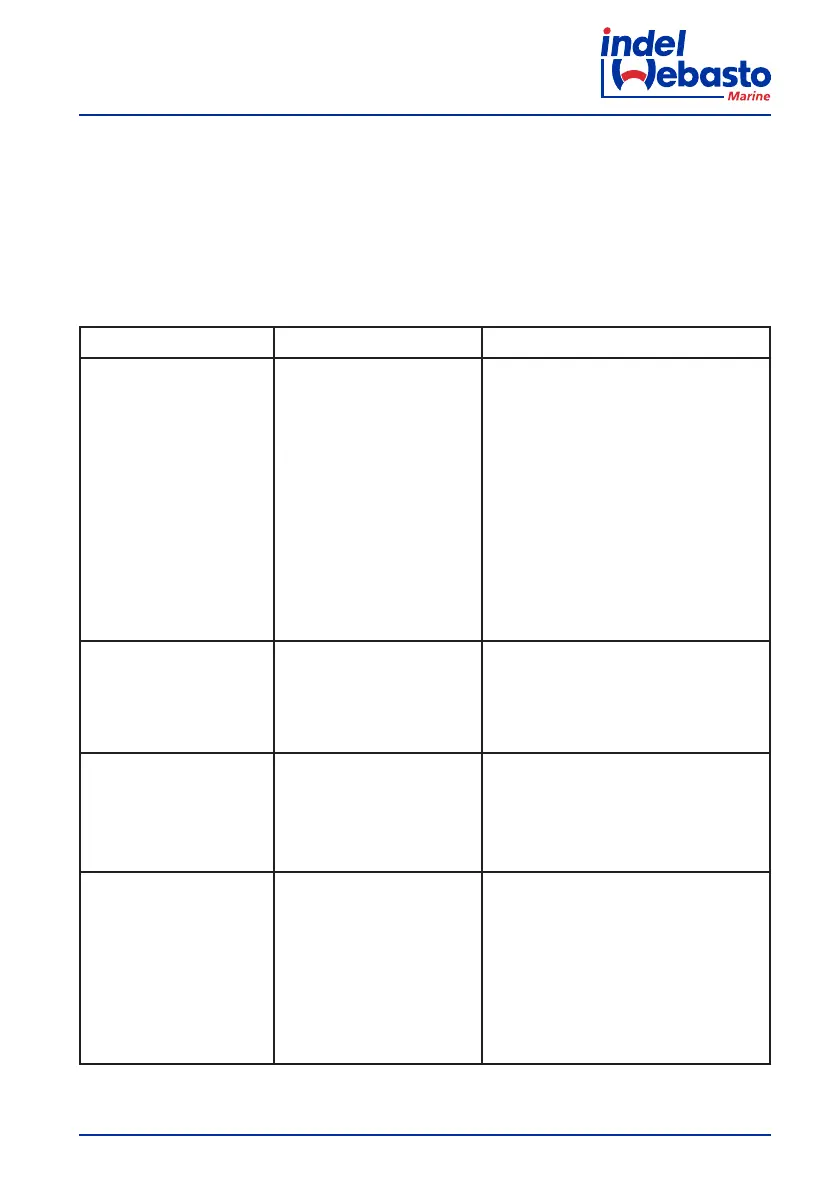

Defect Possible cause Intervenon

The product does not cool,

the compressor will not

start.

No electrical power. Baery

in poor condions. Faulty

thermostat. Defecve

electronic control unit.

Check to make sure that the electronic

control unit is receiving sucient power

and voltage; check the fuse. Verify that the

internal lighng is working and that the

compressor is receiving power. Check the

cables, lugs and connectors. Verify that

the baery is charging properly. Check the

thermostat: Bridge T - C with a separate

cable. If the compressor will not start,

its electronics are probably defecve.

Replace. If the compressor starts up with

the bridge, the thermostat is defecve.

Replace the thermostat.

The compressor only

performs brief aempts at

starng up.

There is insucient voltage or

else a drop in voltage during

the aempt to start. The

protecon device is acvated.

The Baeries are drained.

Check the cables and connecons; remove

any traces of oxidaon or corrosion.

Charge the baeries, start the motor or

connect the baery charger.

The compressor funcons

but doesn’t cool.

Loss of refrigerant through

the evaporator or the tubing.

Tubing clogged.

Carry out a leak check and repair any

leaks, drain and rell the proper amount of

refrigerant. (This operaon must be carried

out by a qualied technician.)

The compressor runs for

a long me but doesn’t

cool properly (reduced

eciency).

Insucient venlaon,

the condensaon unit is

overheang. The fan is not

working properly. There is too

much frost on the evaporator.

The door does not close

properly and lets in warm,

moist air. The condenser is

blocked by dust.

Increase the venlaon. Replace the fan.

Defrost the unit. Correct the posion of

the door and check the gasket. Clean the

condensing unit.

Loading...

Loading...