A22 ENGINE ASSEMBLY II

Crankshaft and Bearing Inspection

1. Inspect the crankshaft journal surfaces and

the crank

pin surfaces for excessive wear and

damage.

2. Inspect the oil seal fitting surfaces of the

crankshaft

front and rear ends for excessive wear and

damage.

3. Replace or repair the crankshaft if any excessive

wear or damage is discovered.

4. Inspect the crankshaft oil ports for obstructions.

5. Use high pressure air to clean the oil ports if neces-

sary.

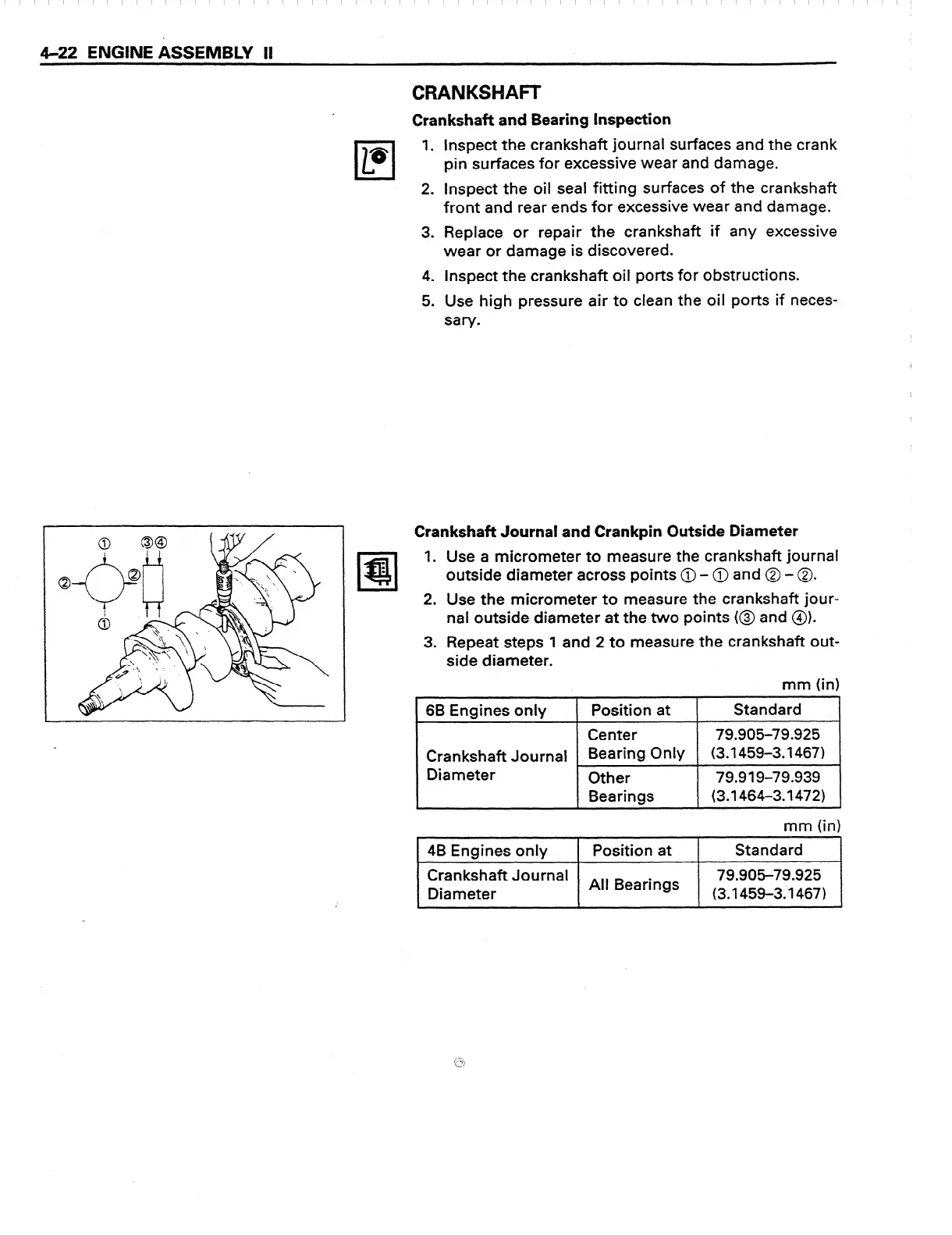

Crankshaft Journal and Crankpin Outside Diameter

1. Use a micrometer to measure the crankshaft journal

outside diameter across points @ - @ and @ - 0.

2. Use the micrometer to measure the crankshaft jour-

nal outside diameter at the two points <@ and @).

3. Repeat steps 1 and 2 to measure the crankshaft out-

side diameter.

mm (in)

1 68 Engines only [ Position at (

Standard

I

Center

79.905-79.925

Crankshaft Journal

Bearing Only

(3.1459-3.1467)

Diameter

Other

79.919-79.939

Bearings

(3.1464-3.1472)

mm (in)

1 4B Engines only 1 Position at

1 Standard 1

Crankshaft Journal

All Bearings

79.905-79.925

Diameter

(3.145%3:1467)

Loading...

Loading...