English – 37

Repair instructions

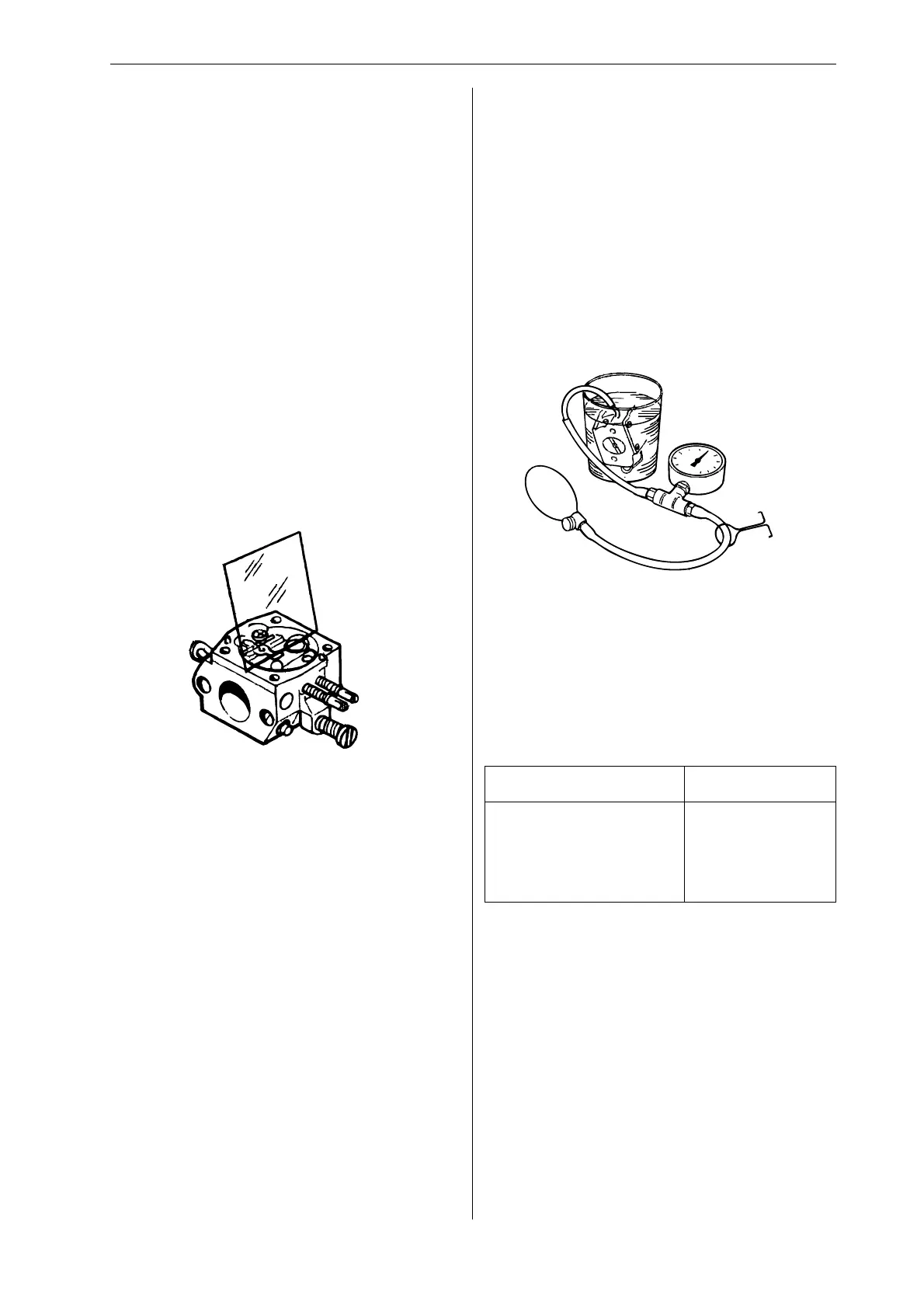

Carburettor – pressure testing

Pressure testing should be carried out with the car-

burettor fully assembled. Testing should always be

carried out after the carburettor has been repaired,

but can also be performed for troubleshooting

before dismantling.

Carry out the test as follows:

• Screw in the high and low speed jet screws and

back them off one turn.

• Connect pressure tester 502 50 38-01 to the

carburettor fuel inlet.

• Lower the carburettor into a beaker of water.

• Pump up the pressure to 50 kPa (0.5 bar) and

clamp the pump tube.

• There should be no leakage. If leakage occurs,

refer to the table below.

Leakage Fault lies in

Diffuser jets Needle valve

In impulse tube Pump diaphragm

Ventilation hole above

metering unit Control diaphragm

Fit the needle valve with lever arm, spindle and

spring and tighten the screw.

Use a rule to check that the lever arm is level with

the cover face. If necessary, the lever arm can be

bent slightly.

7

Fit the metering diaphragm with its gasket and refi t

the cover to the metering unit.

8

Carry out pressure testing.

1

If the throttle and choke butterfl ies and their

spindles were removed, these must be refi tted.

Lubricate the spindle bearings with light oil.

2

Insert the plug in the hole with the convex side

upwards and expand it by pressing downwards

with a drift.

3

Refi t the high and low speed jet screws and

springs, plus the idling screw. Fit the plastic caps

over the high and low speed screws.

4

Fit the fuel fi lter, using the handle of a small screw-

driver.

5

Fit the pump diaphragm, gasket and cover to the

pump unit.

6

Loading...

Loading...