56 – English

Repair instructions

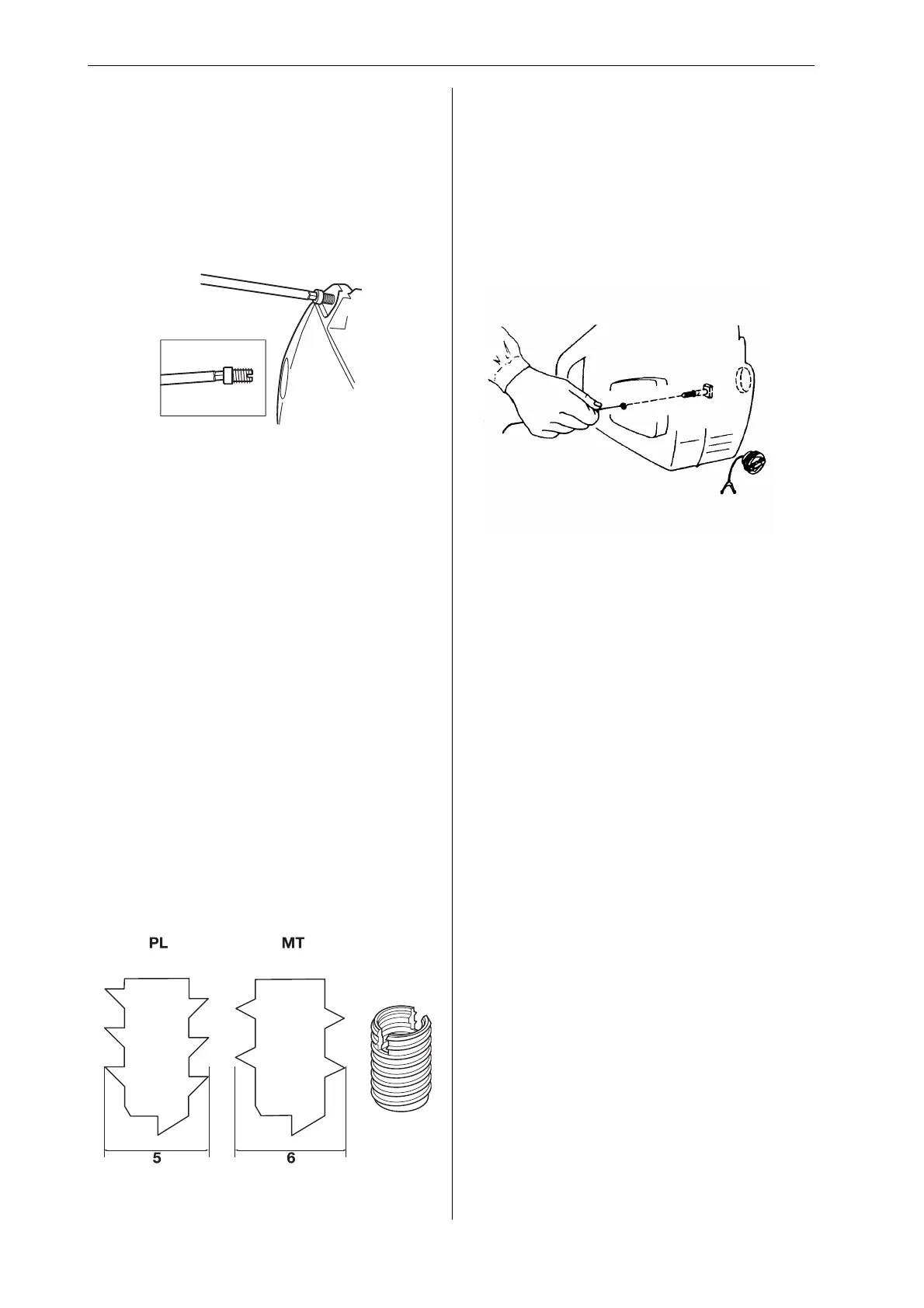

Fasten a steel wire to the thread of the new bolt,

feed the steel wire into the oil tank and out through

the bolt hole in the crankcase.

5

Pull the steel wire until the bolt comes out through

its hole.

6

Pull through the bolt with its nut. Place a spacer

between the nut and crankcase.

7

Check that the square shoulder of the bolt is cor-

rectly seated in the recess in the crankcase.

8

Refi ll with chain oil.

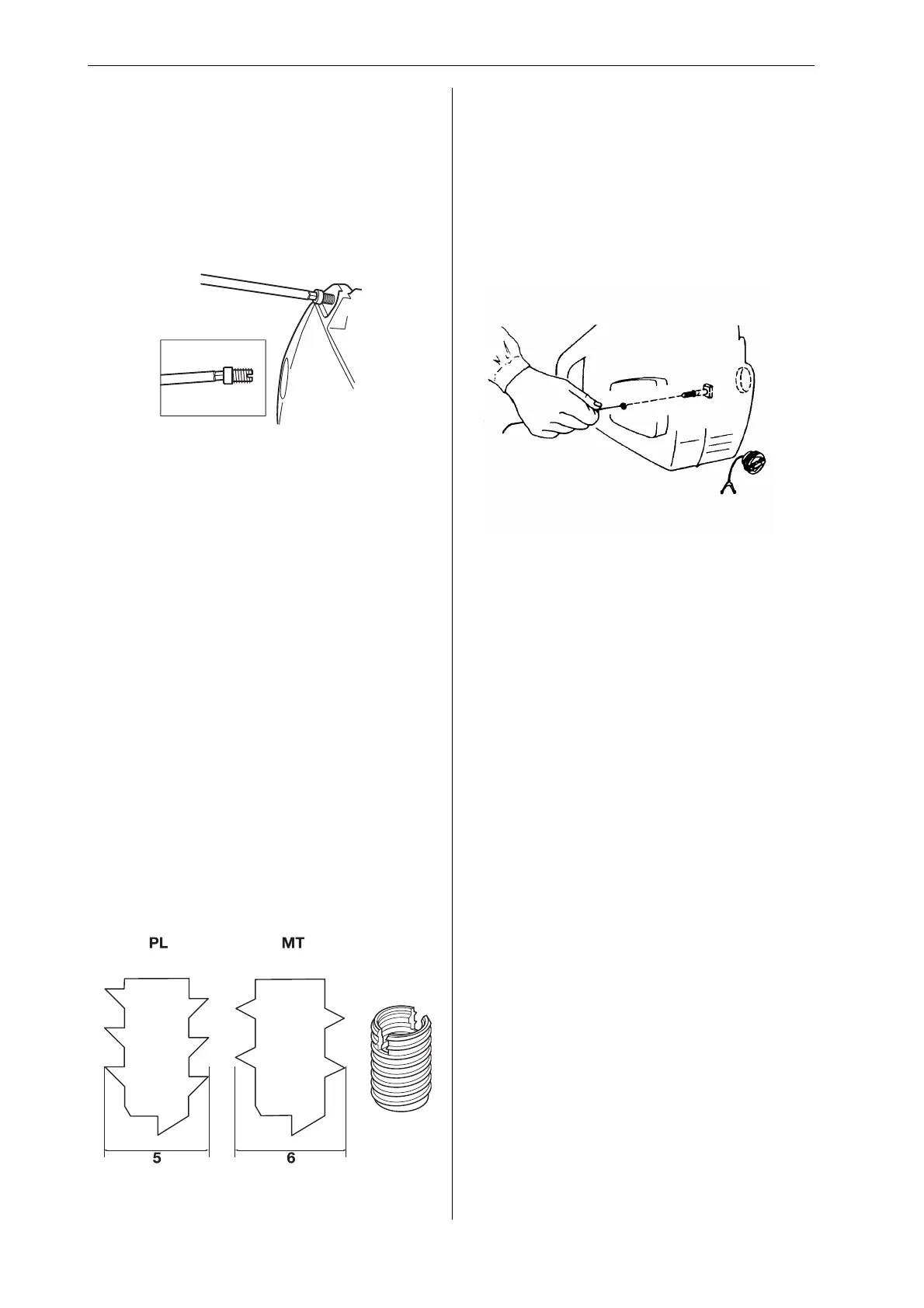

Repairing damaged threads

A repair kit, 503 27 33-01, is available for repairing

damaged threads.

First drill out the hole using:

6.1 mm drill bit for magnesium crankcase

Then screw in the thread insert using a suitable

bolt and spanner.

Thread insert

A damaged thread can be repaired using a thread

insert. The slotted part of the thread insert is

screwed in fi rst, as this is the cutting part.

To repair a thread that was originally designed for

a PL5 screw: fi rst drill out with a 6.1 mm diameter

drill bit, then screw in the thread insert using a suit-

able screw and spanner.

To repair a thread that was originally designed for

a MT6 screw: fi rst drill out with a 7.1 mm diameter

drill bit, then screw in the thread insert using a suit-

able screw and spanner.

This type of thread insert is best suited for use

in plastic and magnesium, but not for repairing

threads in aluminium. In that case use a helicoil

insert with metric screw.

New part no. Description

503 27 39-01 PL5

503 27 40-01 MT6

Guide bar bolts – replacement

1

Drain the oil tank.

2

Knock through the old guide bar bolt so that it falls

into the oil tank.

3

Remove the bolt from the oil tank.

4

Loading...

Loading...