5. TROUBLES AND CORRECTIVE MEASURES

(1) Mechanical components

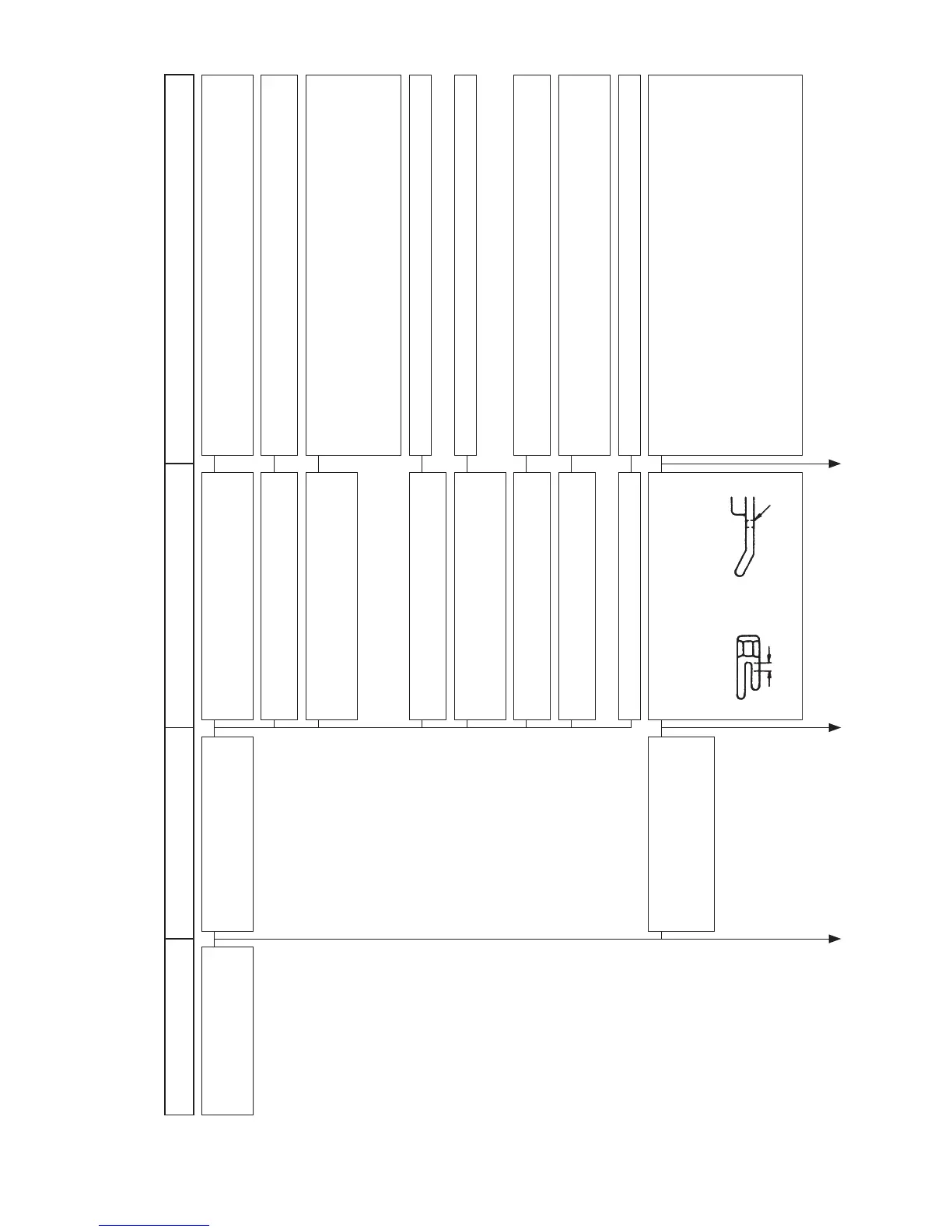

Trouble Cause (1)

a

b

Cause (2) Check and corrective measures

1. Skipping of one or more

stitches occurs at the start

of sewing.

1-1) The needle thread passing

through the needle is too short

after thread trimming.

1)-A Something is wrong with the needle

threat route and the needle thread

tension is too high at thread trimming.

Check the needle thread path. Remove thread entangled with thread

guide pin, or correct the position of the thread guide on the thread stand

or other troubles.

1-2) An inappropriate needle,

throat plate, or presser is used.

Alternatively, the pressure of

the presser is too low.

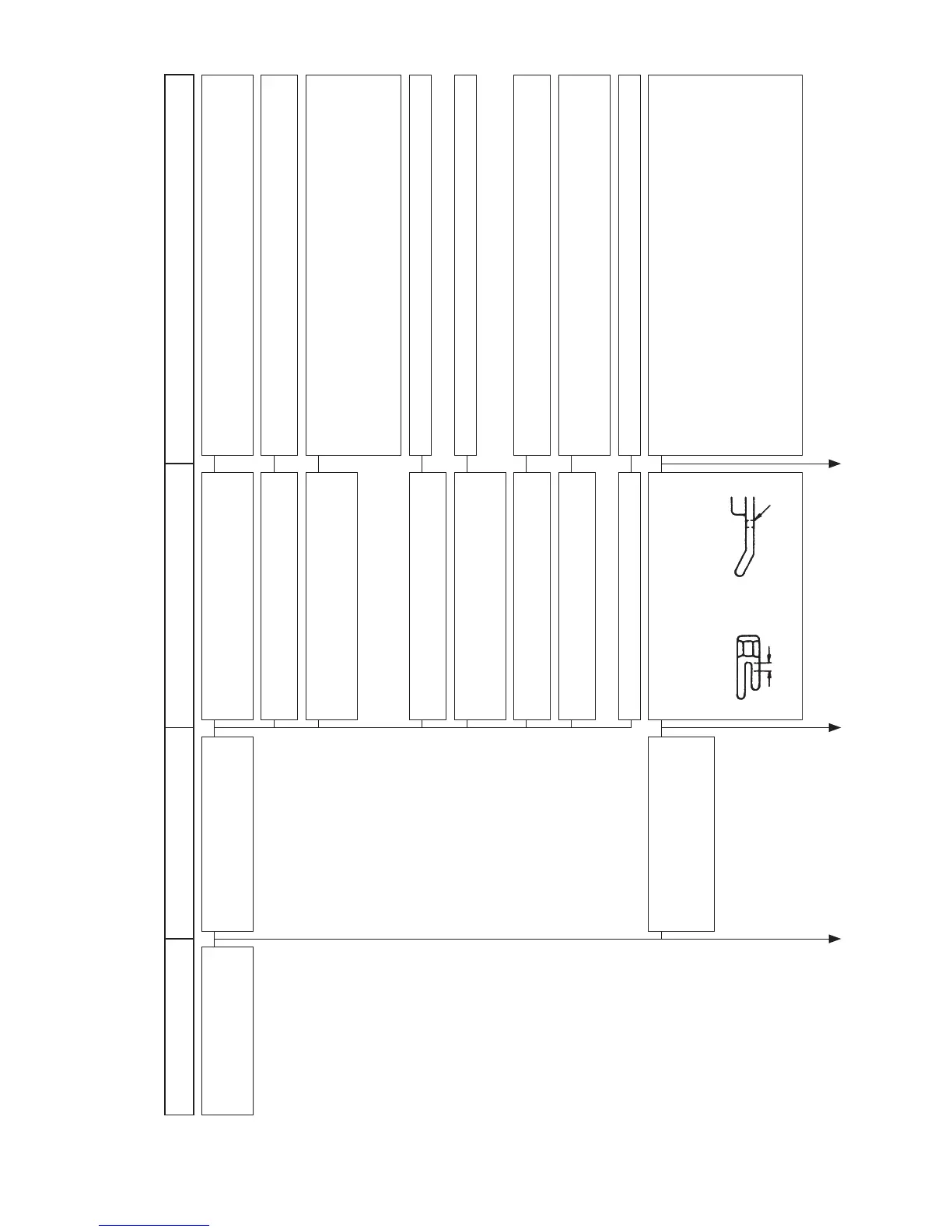

2)-A The presser foot can not hold the needle

thread because “a” dimension of the

relief at “b” of the presser foot is too

large.

Check “a” and “b” of the presser foot, and “A” of the throat plate.

c

When synthetic thread is used for tricot “a”< 0.8 mm, and radius of

“A” and “b”< 0.3 mm.

c

When synthetic thread is used, “a” shall be smaller than 1.2 mm,

and there shall be no relief at “b” and “A”.

c

For cotton thread, the relief at “a”, “b” and “A” should be

minimized as long as good tightness of stitches is obtained.

c

The smaller the relief at “a”, “b”, and “A”, the better for

lighter-weight or coarser fabrics, more slippery thread, or smaller

stitch length.

Turn the thread tension nut of the 1st thread tension disk

counterclockwise to decrease the tension.

Check whether the floating amount of the 2nd thread tension disk reads

between 0.5 and 1 mm when the hook thread presser is pushed into until

the tip of the presser reaches the bobbin. The floating amount is

adjustable by moving the tension release wire on the underside of the

bed. Check whether the disk is horizontally loosened. If not, turn the

thread tension spring 180 degrees or correct the spring inclination.

Check and correct the cam timing in accordance with 3-6.

Check for loosened setscrew of the thread take-up picker.

Removing the throat plate, check and correct the position of the counter

knife, or check for any scratch on the moving knife (Refer to 4-(8)).

Check the hole of the knife thread guide and hook for scratches or burrs,

and if a scratch or burr has been found, buff it. If buffing does not

correct the trouble, replace the components.

Correct the timing for a synthetic thread (special)

1)-B The tension of the 1st thread tension

disk is too high.

1)-C The floating amount of the 2nd thread

tension disk is insufficient at thread

trimming.

1)-D The timing of the tread trimming cam is

too early.

1)-E The needle thread is detached at thread

trimming due to wrong position of the

hook thread presser.

1)-F The counter knife is too close to the

needle, or the knife tip is too sharp.

1)-G The knife thread guide, moving knife,

or hook has a flaw.

1)-H The standard cam timing is too early.

To the next page To the next page To the next page

− 44 −

Loading...

Loading...