101

0 to 0.05 mm

2

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

8-8. Adjusting height of the needle bar

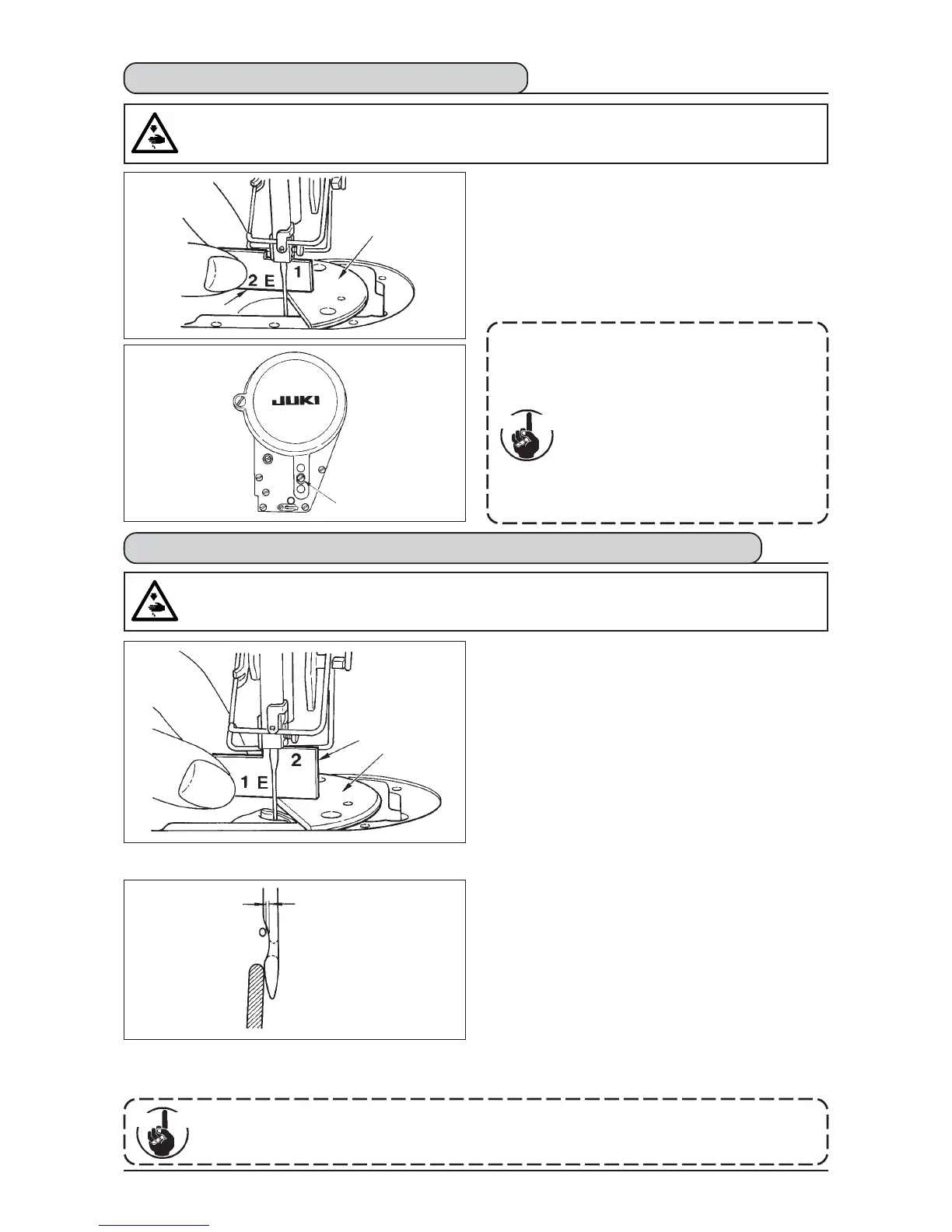

1) Set the zigzag width to “0”. Bring the needle to the

center of the zigzag stroke.

2) Remove the presser foot, throat plate, semicircle

plate and feed dog.

3) Place a semicircle plate on the plane, to which the

throat plate is to be attached, of the bed. Loosen

setscrew 2, and adjust so that from the top surface

of semicircle plate A to the bottom end of the needle

bar is as high as “1” of timing gauge 1.

1. Thickness of the semicircle plate is

different from that of the throat plate. Be

sure to use the semicircle plate when

adjusting the height of the needle bar.

Be sure to perform the adjustment with

zigzag width set to zero and with the

needle positioned at the center of the

zigzag stroke.

2. Use the timing gauge on which the

indication “E” is engraved which has

been supplied as accessories. (Part No.

22536502)

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

8-9. Adjusting the needle-to-hook timing and the needle guard

Cau

tion

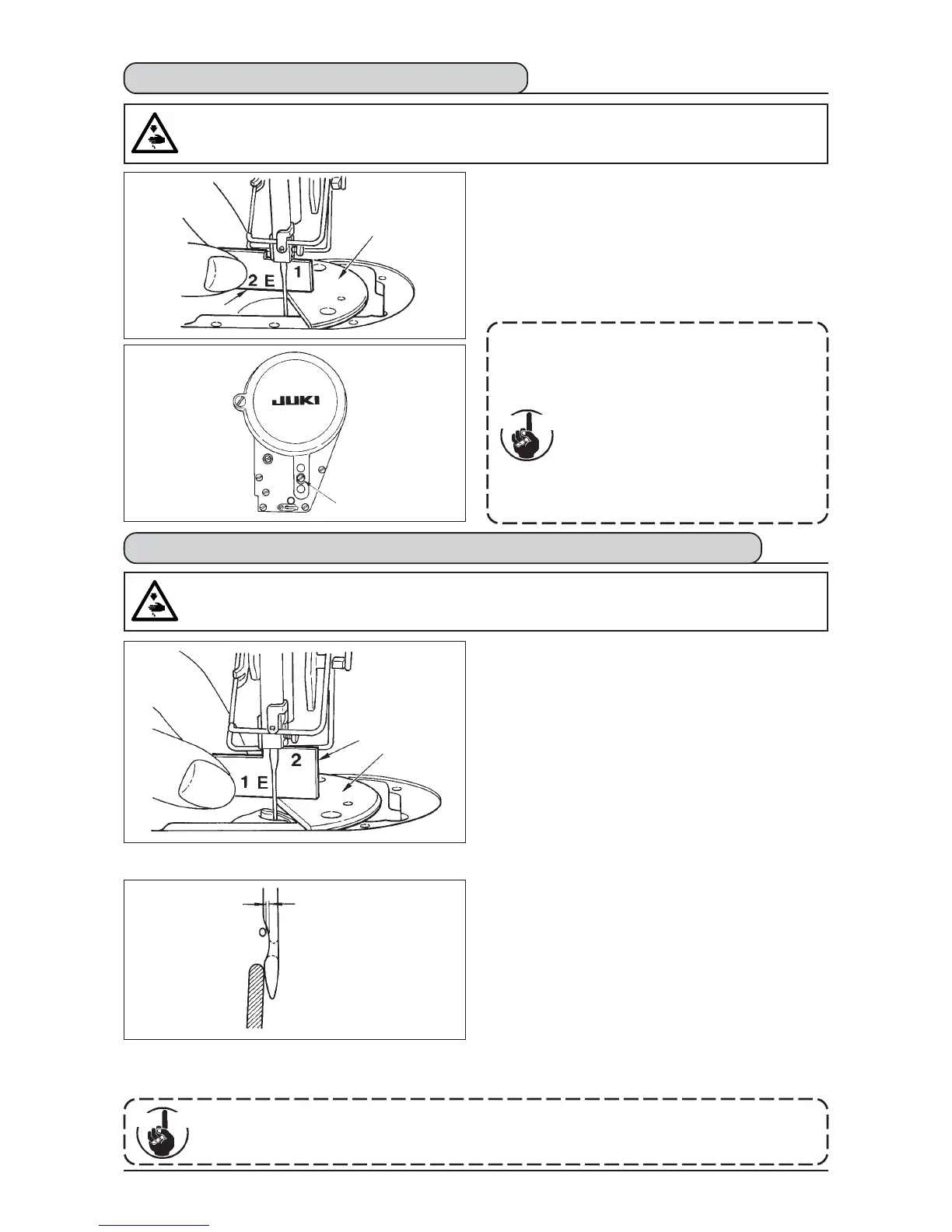

(1) Positioning the hook

1) After the completion of the adjustment of the needle bar

height, adjust so that the blade point of the hook comes to

the center of the needle at the height of the “2” of timing

gauge 1 which has been supplied as accessories.

2) At this time, the blade point of the hook should slightly come

in contact with the needle when the needle guard does not

touch the needle.

(2) Confirmation

Maximize the zigzag width (LZ-2290A : 5 mm). Bring the

needle to the leftmost position of the zigzag stroke.

Now, confirm that the top end of the needle eyelet is spaced

0.2 to 0.5 mm away from the blade point of the hook.

If the zigzag width of 10 mm is used or the shape of indented

part of the needle is different from that of indented part of

the needle at the time of delivery, re-adjust the height of the

needle bar.

(3) Adjusting the needle guard

1) Maximize the zigzag width. Bend the needle guard to adjust

so that the needle does not come in contact with the blade

point of the both at the leftmost and rightmost positions of

the zigzag stroke. At this time, adjust the clearance provided

between the needle and the blade point of the hook to 0 to

0.05 mm.

2) The needle guard functions to keep the needle away from

the blade point of the hook, thereby preventing damage to

the blade point of the hook. Whenever you have replaced

the hook with a new one, be sure to adjust the position of

the needle guard.

A

1

A

1

Cau

tion

When thread breakage has occurred, there is a case where thread is caught in the hook.

Be sure to perform sewing after removing the thread caught in the hook.

Loading...

Loading...