– 96 –

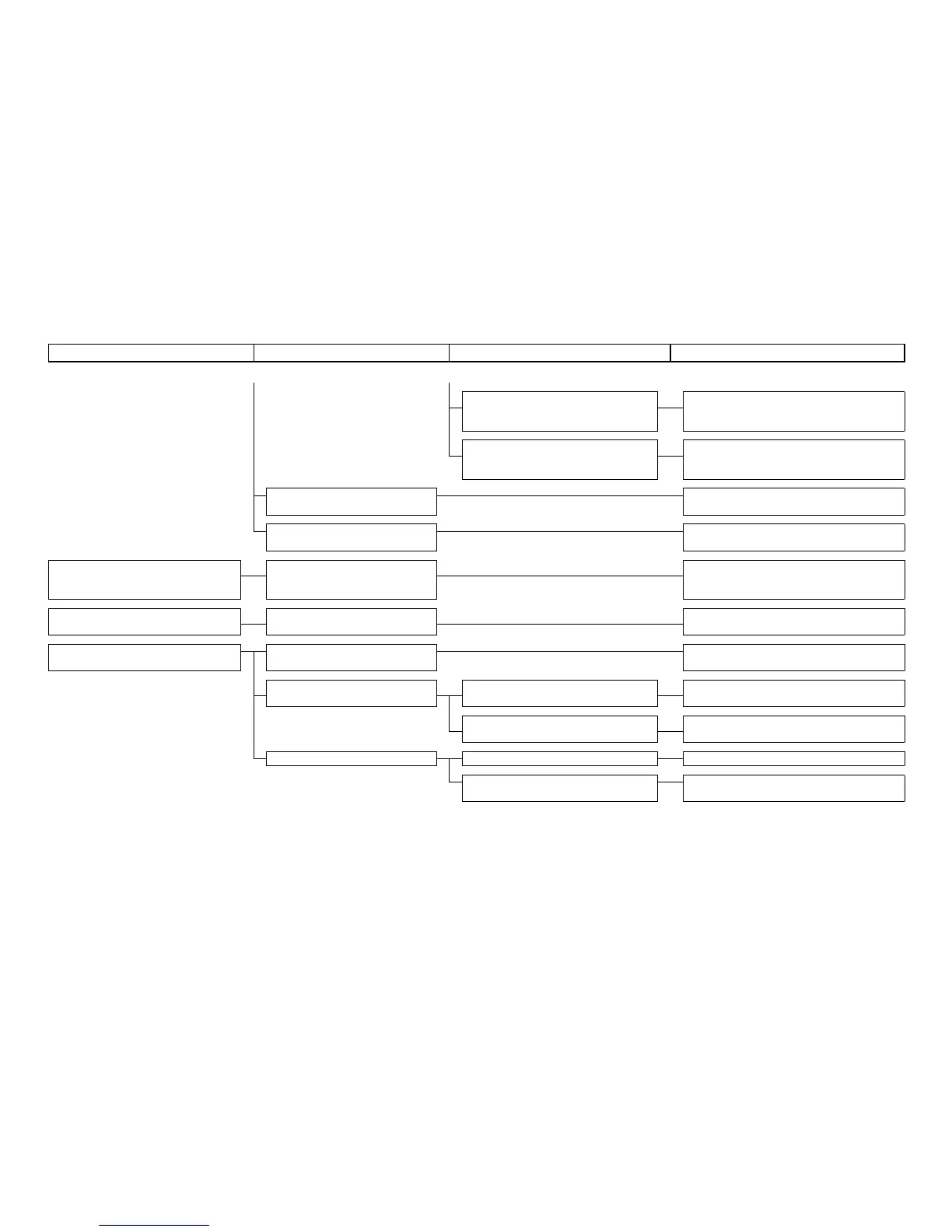

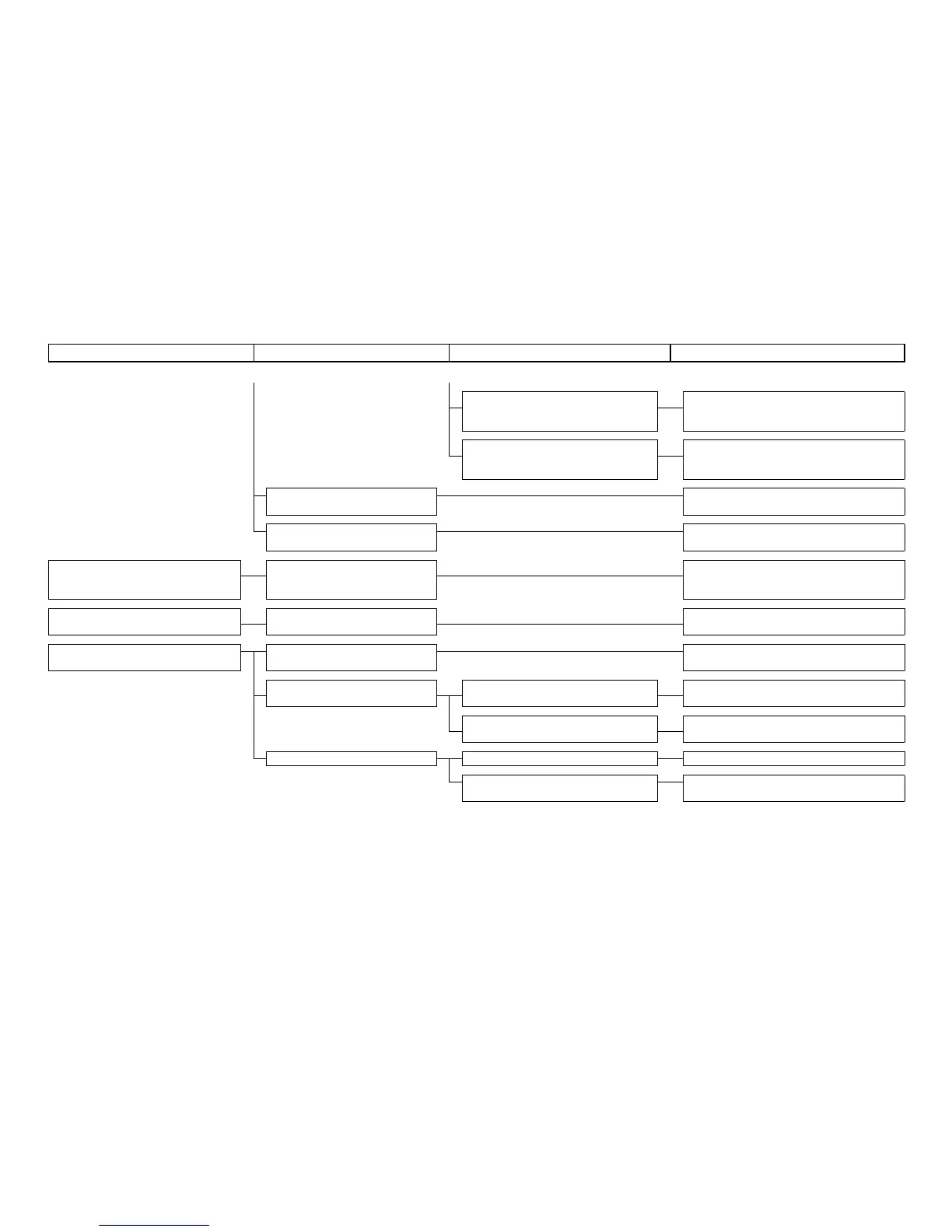

Trouble Cause (1) Cause (2) Check and corrective measures

From the previous page From the previous page

4-B) Friction is excessive between the

Y feed arm and the cloth feed

support plate.

Install the cloth feed support plate.

4-C) The feed plate or the work clamp

foot is caught by the needle hole

guide.

Tighten the set screw further for the needle

hole guide.

3-5) Inadequate adjustment of

the X sensor position

Adjust the X sensor position correctly.

3-6) Inadequate adjustment of

the Y slit plate

Adjust position of the Y slit plate correctly.

4. Sewing machine locked 4-1) Large needle compared

with the hole diameter of

the needle hole guide

Replace the needle hole guide.

5. Severe vibration 5-1) Inadequate crank balancer

positioning

Dene the correct crank balancer position.

6. Malfunction of vertical movement

of work clamp foot

6-1) Looseness of thread trim-

mer cam screw

Dene the thread trimmer cam position and

x the cam.

6-2) Presser pulse motor mal-

function

2-A) Defective the presser pulse mo-

tor.

Replace the presser pulse motor.

2-B) The presser pulse motor is

wrongly connected.

Check the connector connections.

6-3) Defective circuit board 3-A) Circuit board programming aw. Replace the circuit board.

3-B) Connector connections are

wrongly made.

Check the connector connections.

Loading...

Loading...