– 106 –

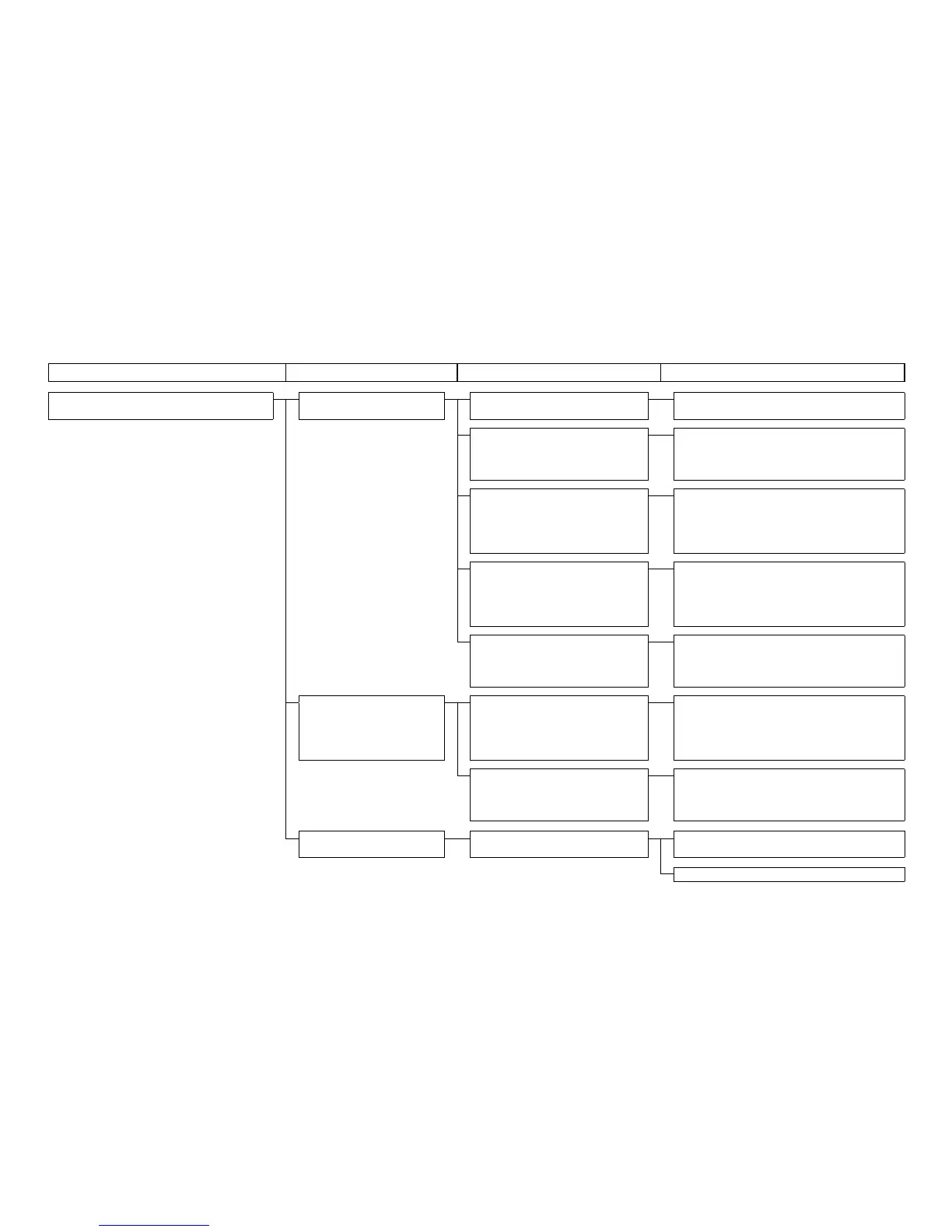

Trouble Cause (1) Cause (2) Check and corrective measures

1. No display at the operation panel. 1-1) DC power is not sup-

plied.

1-A) AC power is not supplied. Examine if a power supply is available at the

power switch.

1-B) The FLT board has no power

supply.

Check whether an AC voltage is available

between Pins 4-5 of CN1 in the FLT board.

If no voltage is found, check the connections

around the power switch.

1-C) The SDC board has no power

supply.

Check whether DC 280V is available be-

tween Pins 1-3 of CN17 in the SDC board. If

no voltage is found, check the connections

toward the FLT board. If there is no problem

in connections, replace the FLT board.

1-D) The MAIN board has no

power supply.

Check whether DC 5V is available between

Pins 4-8 of CN31 in the MAIN board. Check

the power supply for the SDC board unit and

examine if there is short-circuiting in the 5V

power system.

1-E) The operation panel has no

power supply.

Conrm that the cable from the operation

panel is connected to CN34 of the MAIN

board. If there is no

problem in connections,

replace the MAIN or PANEL board.

1-2) Detection of a mo-

mentary interruption in

the SDC board.

LED3 on SDC board:

Flashing 9 times

2-A) There is no connection be-

tween CN3 of the FLT board

and CN13 of the SDC board.

Check the connection between CN3 of the

FLT board and CN13 of the SDC board.

2-B) No AC voltage is available

between Pins 4-5 of CN1 in

the FLT board.

When a sewing machine for 3-phase speci-

cations is used in a 1-phase system, con-

nect the power supply to red and white of the

power cord led from the box.

1-3) Difference in source

voltage

3-A) High input voltage Check the 100/200V selector cord in the FLT

board.

Check the source voltage.

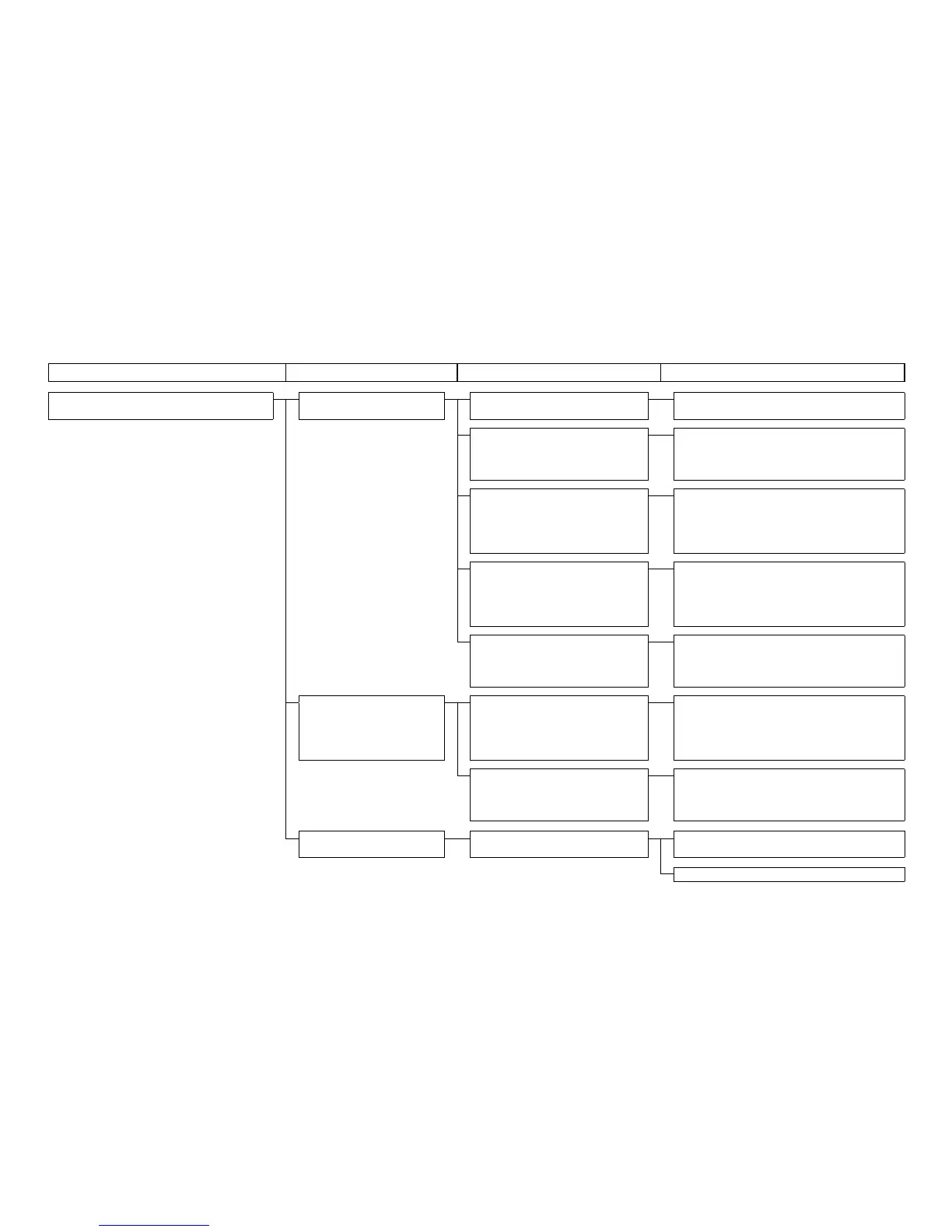

(3) Electrical components

(Refer to "Block diagram A".)

Loading...

Loading...