– 95 –

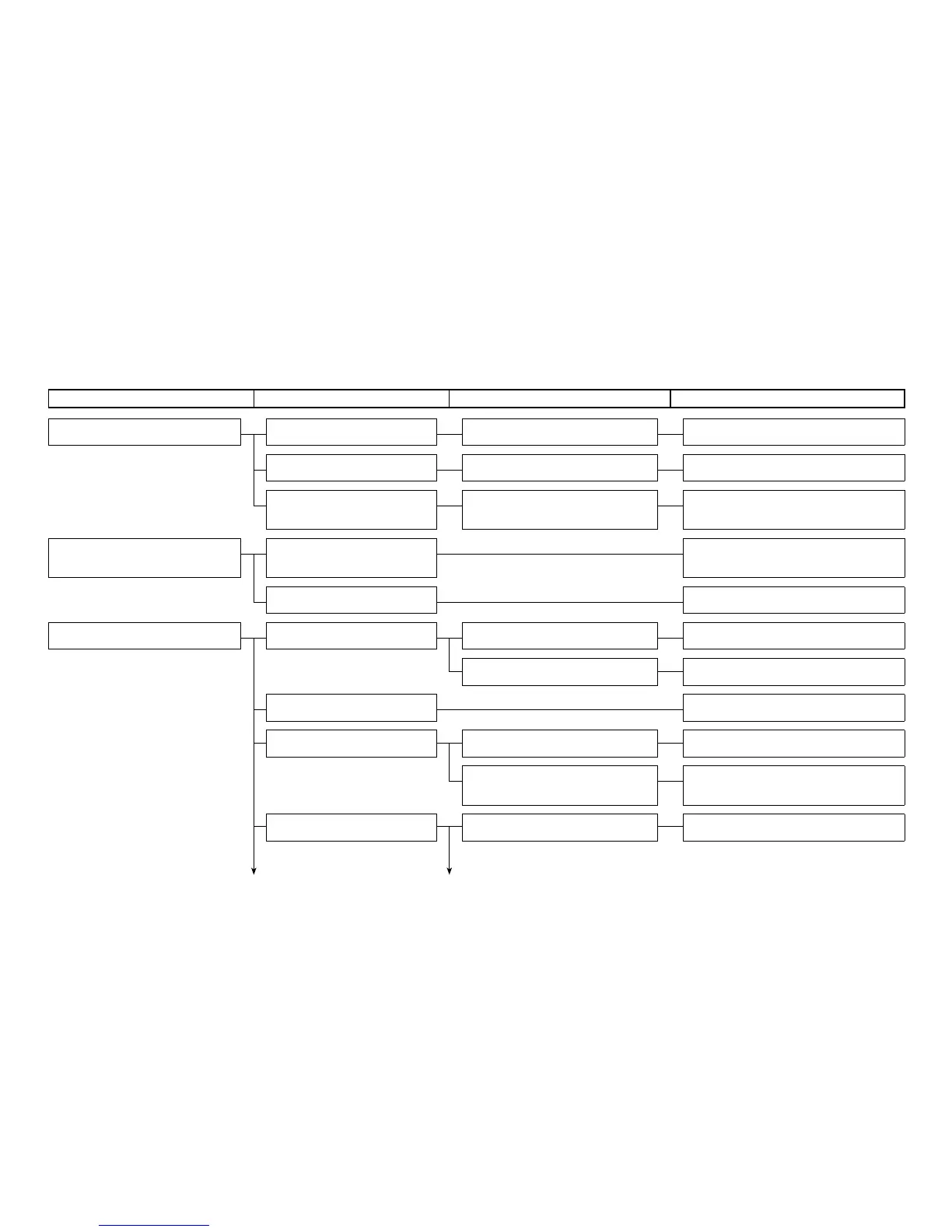

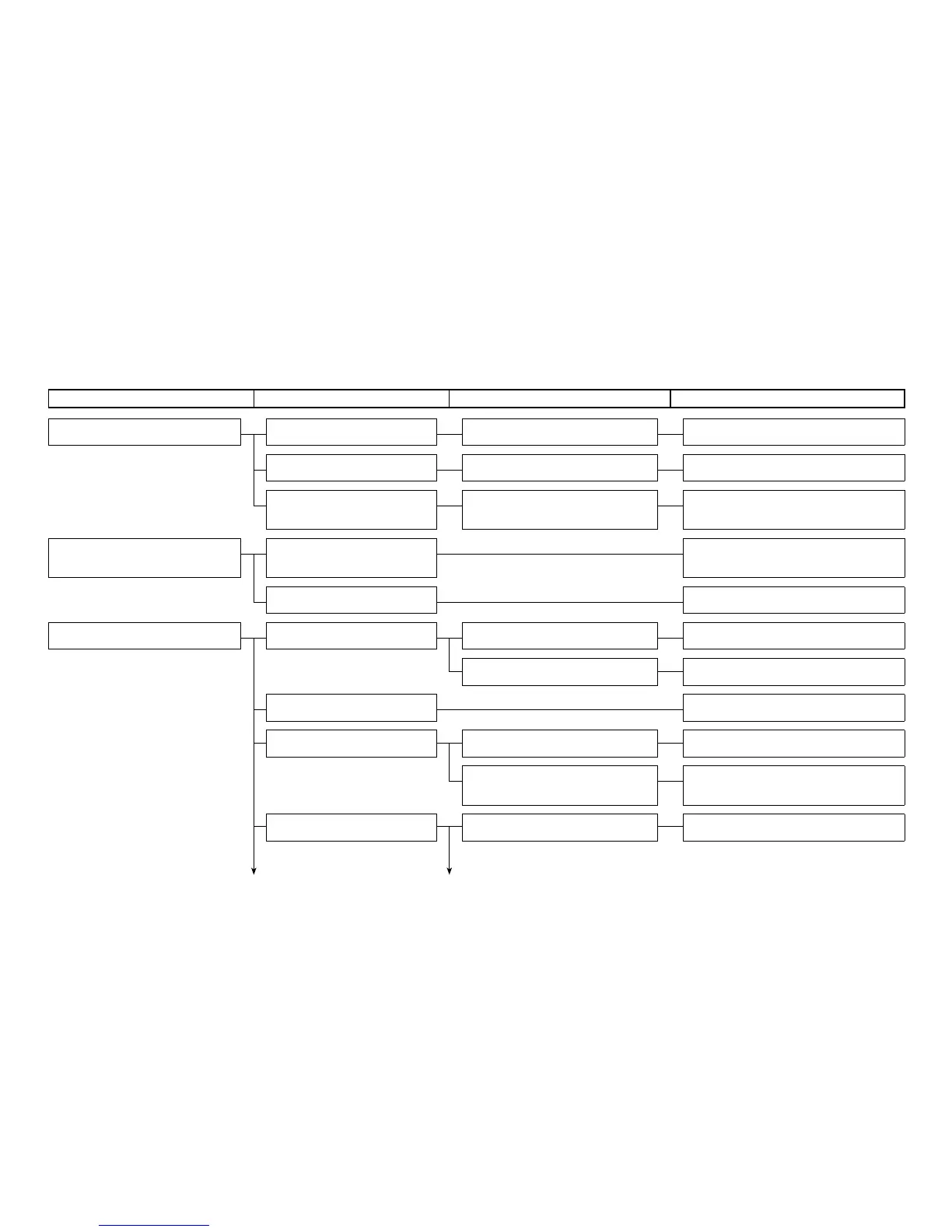

Trouble Cause (1) Cause (2) Check and corrective measures

1. Wiper cannot spread a thread. 1-1) Interference between wiper

and needle

1-A) Wiper mounting position is inad-

equate.

Adjust the wiper position.

1-2) Displacement of front-rear

wiper position

2-A) Wiper mounting position is inad-

equate.

Adjust the wiper position.

1-3) Thread holding before

wiper action

3-A) The right left wiper mounting po-

sition is inadequate (insufcient

distance to the needle).

Adjust the wiper position.

2. Abnormal noise 2-1) Backlash between the

oscillator and the shuttle

driver shaft is large.

Check oscillator gear positioning and adjust

the lower shaft gear backlash.

2-2)

Too much clearance between

inner hook and shuttle driver

Adjust the clearance between inner hook

and shuttle driver

3. Deformation in sewn patterns 3-1) Too much backlash in the

Y feed gear

1-A) Backlash is too much in the Y

feed arm and the motor base.

Adjust backlash of motor base.

1-B)

Backlash is too much in the Y feed

pulse motor and the motor base.

Adjust backlash of Y feed pulse motor.

3-2) Too much backlash in the

X feed gear

Adjust backlash of the X feed gear.

3-3) Travelling torque in X di-

rection is excessive.

3-A) The motor is pressed against the

X feed arm too strongly.

Adjust backlash of the motor.

3-B) The feed plate or the work clamp

foot is caught by the needle hole

guide.

Tighten the set screw further for the needle

hole guide.

3-4) Travelling torque in Y direc-

tion is excessive.

4-A)

The pulse motor is pressed against

the Y feed shaft too strongly.

Adjust backlash of the feed motor gear.

To the next page To the next page

11. Troubles and corrective measures

(1) Mechanical parts

Loading...

Loading...