– 29 –

ENGLISH

I

n addition, there are the following error codes in this device. These error codes interlock (or limit function) and inform the problem so

that the problem is not enlarged when any problem is discovered. When you request our service, please conrm the error codes.

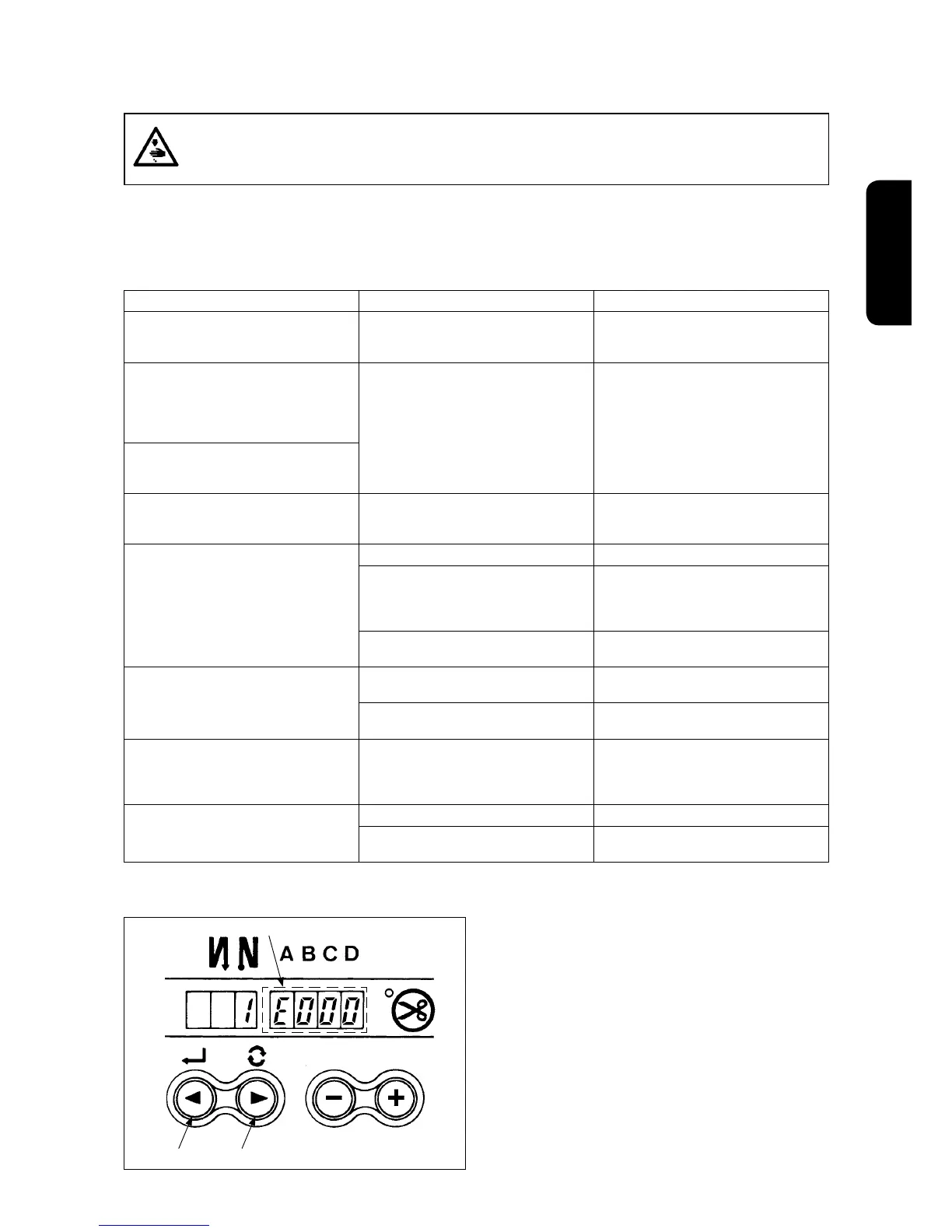

Checking procedure of the error code

1) Pressing switch

1

in the control box, turn ON the

power switch.

2) LED becomes display

5

with the sound of “peep”

and the latest error code is displayed.

3) Confirmation of the contents of previous error

can be performed by operating switches

1

or

2

.

(Caution) When operating switch

1

, one before

the existing error code is displayed.

When operating switch

2

, one after the

existing error code is displayed.

2. Error codes

In case of the following, check again before you judge the case as trouble.

WARNING :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing machine,

removethecoverafterturningOFFthepowerswitchandalapseof5minutesormore,andconrm

the trouble to manage.

Phenomenon Cause Corrective measure

Solenoids for thread trimming, reverse feed,

wiper, etc. fail to work. Hand lamp does not

light up.

When the fuse for solenoid power protection

has blown out

Check the fuse for solenoid power protection.

Even when depressing the pedal immedi

-

ately after turning ON the power, the sewing

machine does not run. When depressing the

pedal after depressing the back part of pedal

once, the sewing machine runs.

Neutral position of the pedal has varied.

(Neutral position may be shifted when chang-

ing spring pressure of the pedal or the like.)

Execute the automatic neutral correction

function of the pedal sensor.

The sewing machine does not stop even

when the pedal is returned to its neutral

position.

Stop position of the sewing machine varies

(irregular).

When tightening the screw in the handwheel

is forgotten at the time of adjustment of nee

-

dle stop position.

Securely tighten the screw in the handwheel.

Presser foot does not go up even when

auto-lifter device is attached.

Auto-lifter function is OFF.

Select “FL ON S” by auto-lifter function selection.

Pedal system is set to KFL system. When lifting the presser foot by depressing

the back part of pedal, change the setting to

PFL setting. (For the setting procedure, refer

to the Engineer’s Manual.)

Cord of auto-lifter device is not connected to

connector (CN37).

Connect the cord properly.

Touch-back switch fails to work. Presser foot is going up by auto-liter device. Operate the switch after the presser foot

lowered.

Auto-lifter device is not attached. However,

auto-lifter function is ON.

Select “FL OFF” when auto-lifter device is not

attached.

UP position move fails to work when all

lamps on the panel light up.

The mode is in the function setting mode.

The switch on the CTL p.c.b. is pressed by

the bound cords and the aforementioned

mode resulted.

Remove the front cover, and arrange the

cords by the regular binding procedure de-

scribed in the Instruction Manual.

Sewing machine fails to run. Motor output cord (4P) is disconnected.

Connect the cord properly.

Connector (CN30) of motor signal cord is

disconnected.

Connect the cord properly.

* This device is designed so that "system-down" occurs to protect the breakdown of electrical components

when high-voltage such as thunders, etc. is applied for a short time.

At this time, the indication goes out and the sewing machine does not operate.

<Corrective measure>

Turn OFF the power switch, remove the cause and turn ON the power switch after the red LED inside the

control box that can be seen from the power connector section has gone out.

2

1

5

Loading...

Loading...