– 30 –

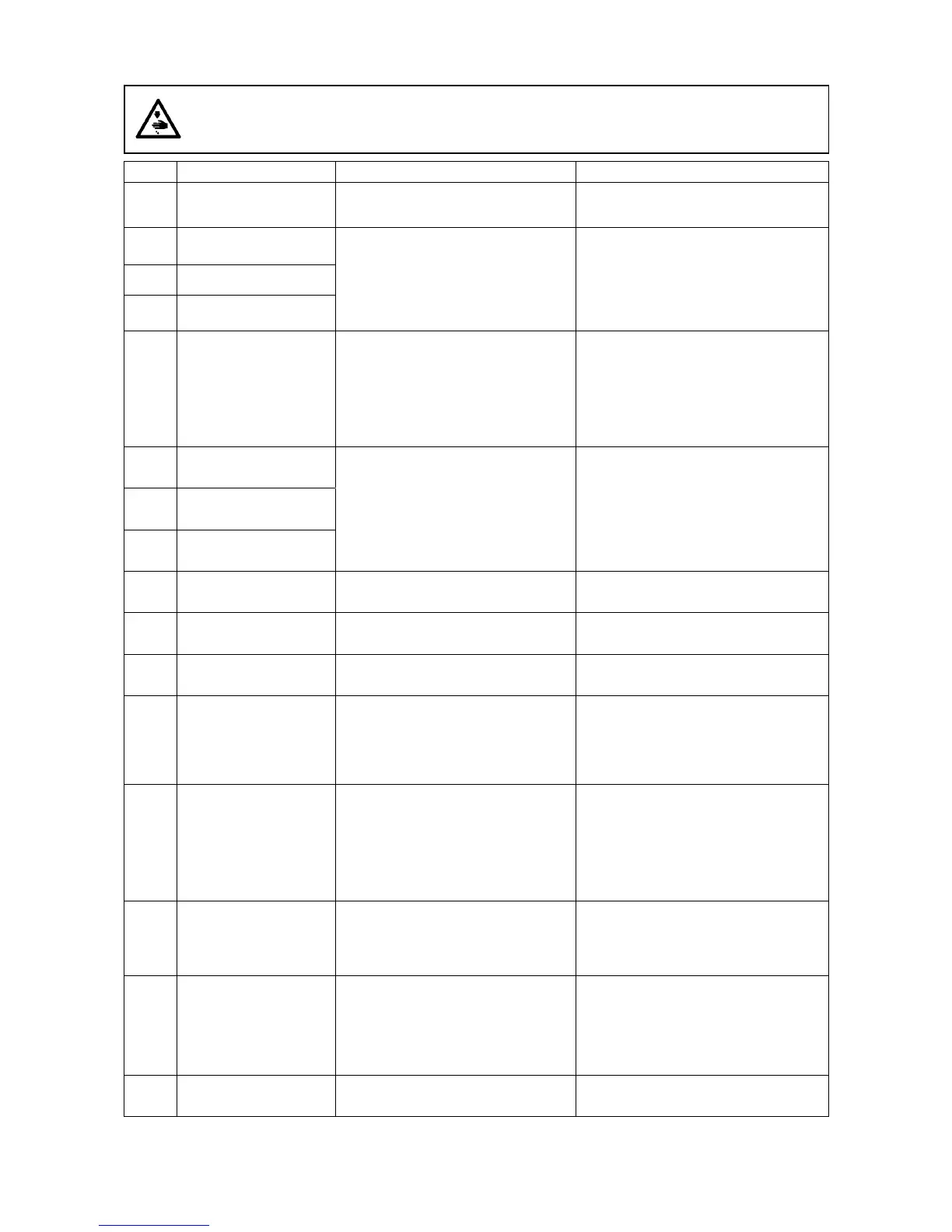

No.

Description of error detected

Cause of occurrence expected Items to be checked

E000 Execution of data ini-

tialization (This is not the

error.)

• When the machine head is changed.

• When the initialization operation is ex-

ecuted

E003 Disconnection of synchro-

nizer connector

• When position detection signal is not

input from the sewing machine head

synchronizer.

• When the synchronizer has broken.

• Belt is loosened.

• Check the synchronizer connector (CN33)

for loose connection and disconnection.

• Check whether the synchronizer cord has

broken since the cord is caught in the

machine head.

• Tension of the belt

E004 Synchronizer lower posi-

tion sensor failure

E005 Synchronizer upper posi-

tion sensor failure

E007 Overload of motor • When the machine head is locked.

•

When sewing extra-heavy material be-

yond the guarantee of the machine head.

• When the motor does not run.

• Motor or driver is broken.

• Check whether the thread has been entan-

gled in the motor pulley.

• Check the motor output connector (4P) for

loose connection and disconnection.

• Check whether there is any holdup when

turning the motor by hand.

E303 Woodruff plate sensor error • When the motor signal is not properly

inputted.

• Check the motor signal connector (CN30)

for loose connection and disconnection.

• Check whether the motor signal cord has

broken since the cord is caught in the

machine head.

E730 Motor hole sensor failure

E731 Bobbin thread remaining

amount sensor unit failure

E808 Solenoid voltage abnor-

mality

• Short-circuit of solenoid cord • Check that cord is caught in the metallic

section.

E809 Presser lifter solenoid

switch abnormality

• When solenoid, the specication of

which is different is used

• Solenoid resistance

E810 Solenoid current abnor-

mality

• Solenoid rare short-circuit. • Solenoid resistance

E811 Overvoltage • When voltage higher than guaranteed

one is inputted.

• 400V is applied to the box of 220V (230V)

In these cases, there is the possibility that

the power circuit board has broken.

• Check whether the applied power voltage

is higher than the rated voltage + (plus)

10% or more.

• Check whether voltage setting of

220/230/240 V is improperly set.

E813 Low voltage • When voltage lower than guaranteed

one is inputted.

• 110V has been inputted to SC-810 of

220V specications.

• 110V is applied to the box of 220V.

• Inner circuit is broken by the applied

overvoltage

• Check whether the voltage is lower than

the rated voltage – (minus) 10% or less.

• Check whether regenerative resistance

connector (CN11) is disconnected.

• Check whether fuse or regenerative resist-

ance is broken.

E904

Solenoid power abnormality

• Solenoid power protection fuse has

broken.

• Conrmation of solenoid power protection

fuse

(Error indication is displayed only for

approximately 0.5 second immediately

after turning ON the power.)

E906 Operation panel transmis-

sion failure

• Disconnection of operation panel cord

• Operation panel has broken.

• Check the operation panel connector

(CN38) for loose connection and discon-

nection.

• Check whether the operation panel cord

has broken since the cord is caught in the

machine head.

E924 Encoder failure • Motor driver has broken.

• Motor overload operation • Motor driver heat is excessive.

Error code list

WARNING :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing machine,

removethecoverafterturningOFFthepowerswitchandalapseof5minutesormore,andconrm

the trouble to manage.