– 11 –

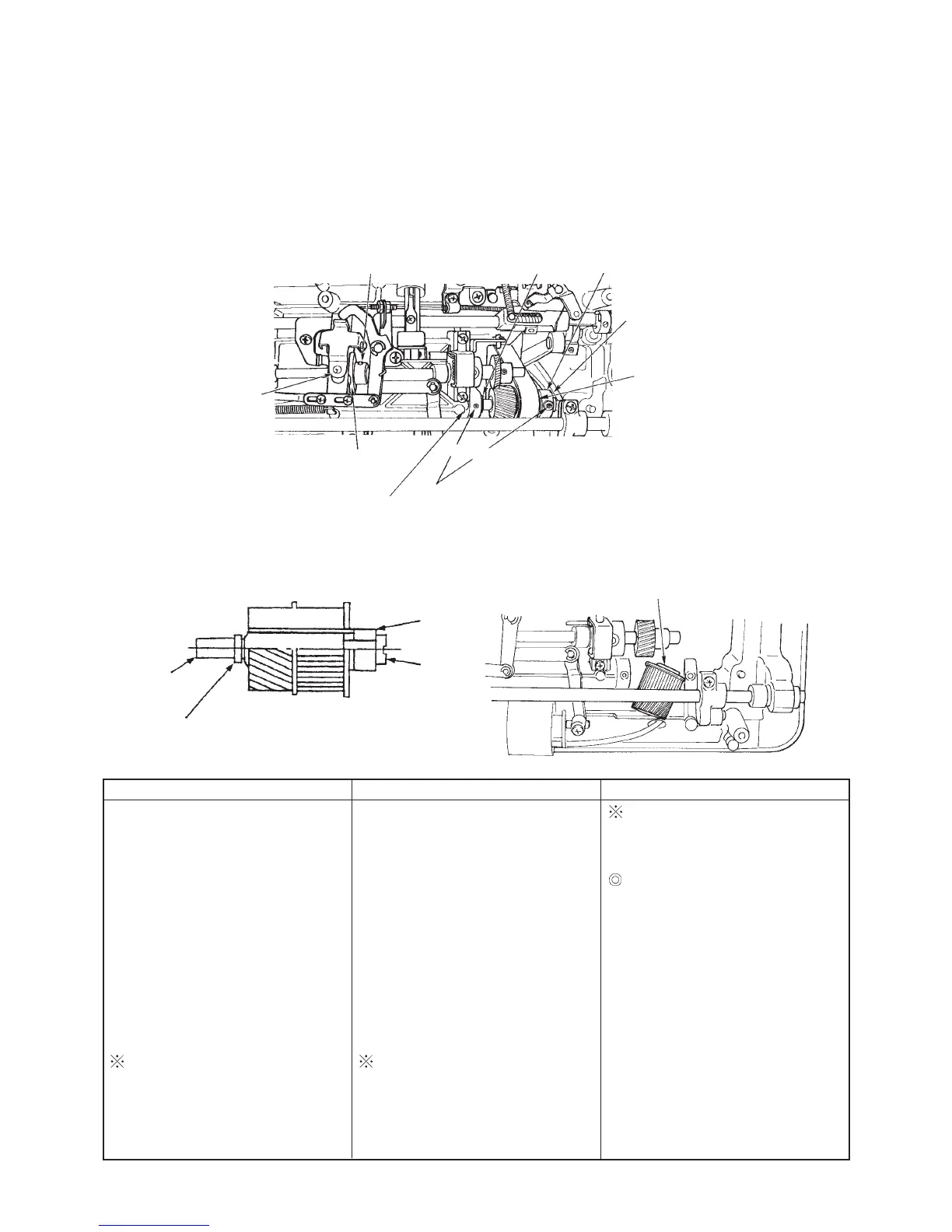

13. Hook driving shaft pulley

Preparation

™ Remove outer components.

(Excluding stop solenoid)

™ Loosen idler.

™ Remove needle.

8 E-ring groove

6

4

5

Make 7 hook driving shaft pulley

come out downward.

!0 Moving knife

roller arm

!1 Thread trimmer cam

2 Hook driving shaft pulley eccentric shaft

setscrew

SM8040602TP

Hexagon 2.0 mm

5 Hook driving shaft pulley eccentric shaft

9 Thread trimmer

cam screw No. 1

3 Hook driving shaft

pulley

E-ring (E-6)

6 Hook driving shaft pulley eccentric

shaft bushing

Slit on 4 hook driving shaft pulley

eccentric shaft

1 Timing belt

A

B

Disassembly

™ Remove timing belt from main

shaft pulley.

Remove belt of 1 and loosen two

setscrews of 2.

Remove E-6 of 3 and turn 4 to find

a place where backlash in hook

driving shaft pulley is large.

Press 5 and push out bushing of 6

to the right side.

Draw out 5 and 6, and remove 7

following the point of 7.

Do not make a flaw on E-ring

groove 8 when removing E-ring

3.

Assembly

™ Enter hook driving shaft pulley

7.

™ Enter eccentric shaft 5 and 6.

™ Set E-ring 3.

™ Remove the play in hook driving

shaft with 6 and tighten setscrew

2 B.

™ Turn shaft slit 4 to adjust

backlash in pulley and tighten

setscrew 2 A.

™ Set belt 1.

Adjust backlash in eccentric shaft

by right rotation.

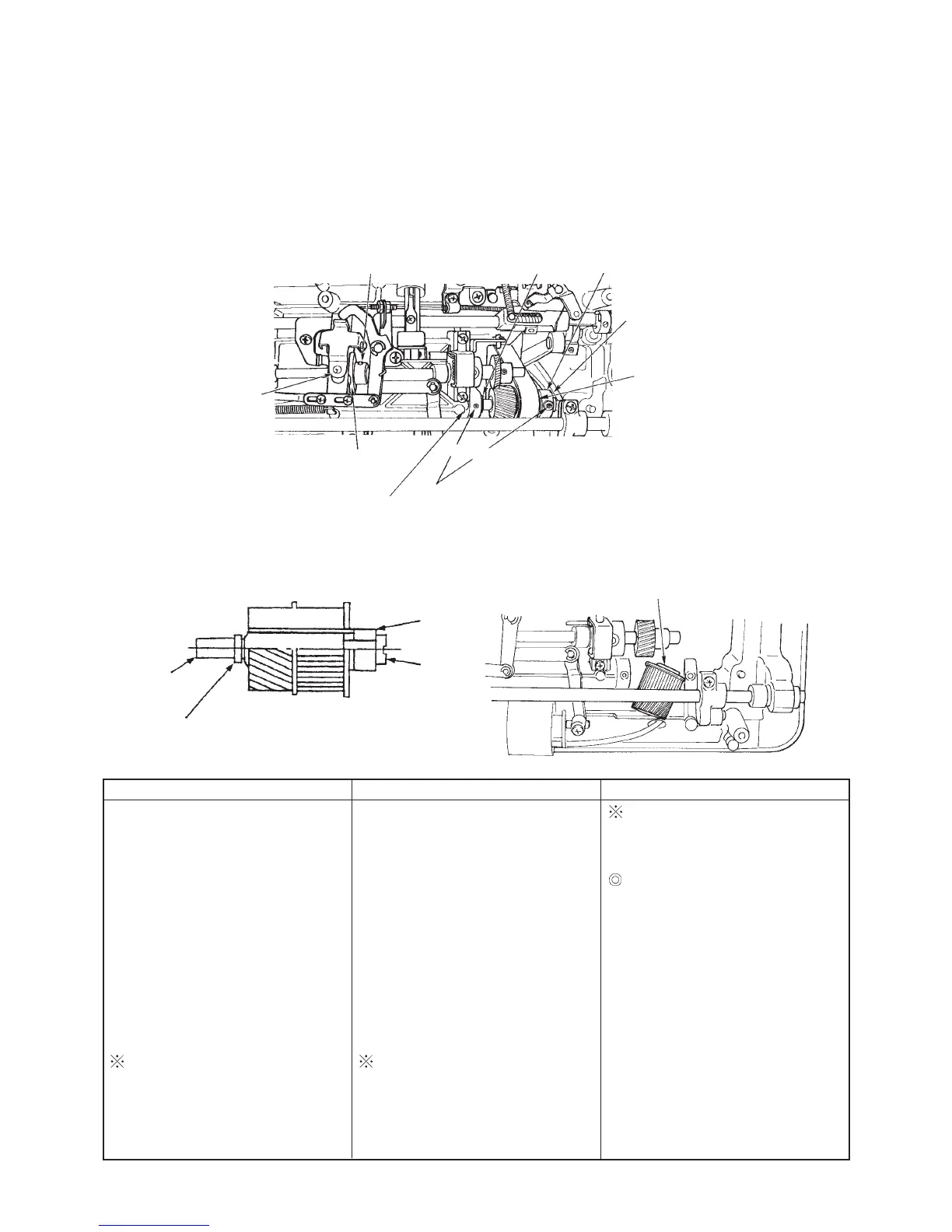

Point

When setting bushing 6, do not

make a flaw on the end face of

bushing.

When setting belt onto main shaft,

refer to thread trimming timing.

(Simple method)

™ Lower needle bar 1.93 mm from

its upper dead point.

™ Turn hook driving shaft and orient

screw No. 1 9 to this side (just

front).

™Enter contact of roller arm !0 to

groove of cam !1.

™ Turn hook driving shaft in the

reverse direction and set belt at

the position where it stops.

(Illustration of hook driving shaft pulley)

Loading...

Loading...