– 18 –

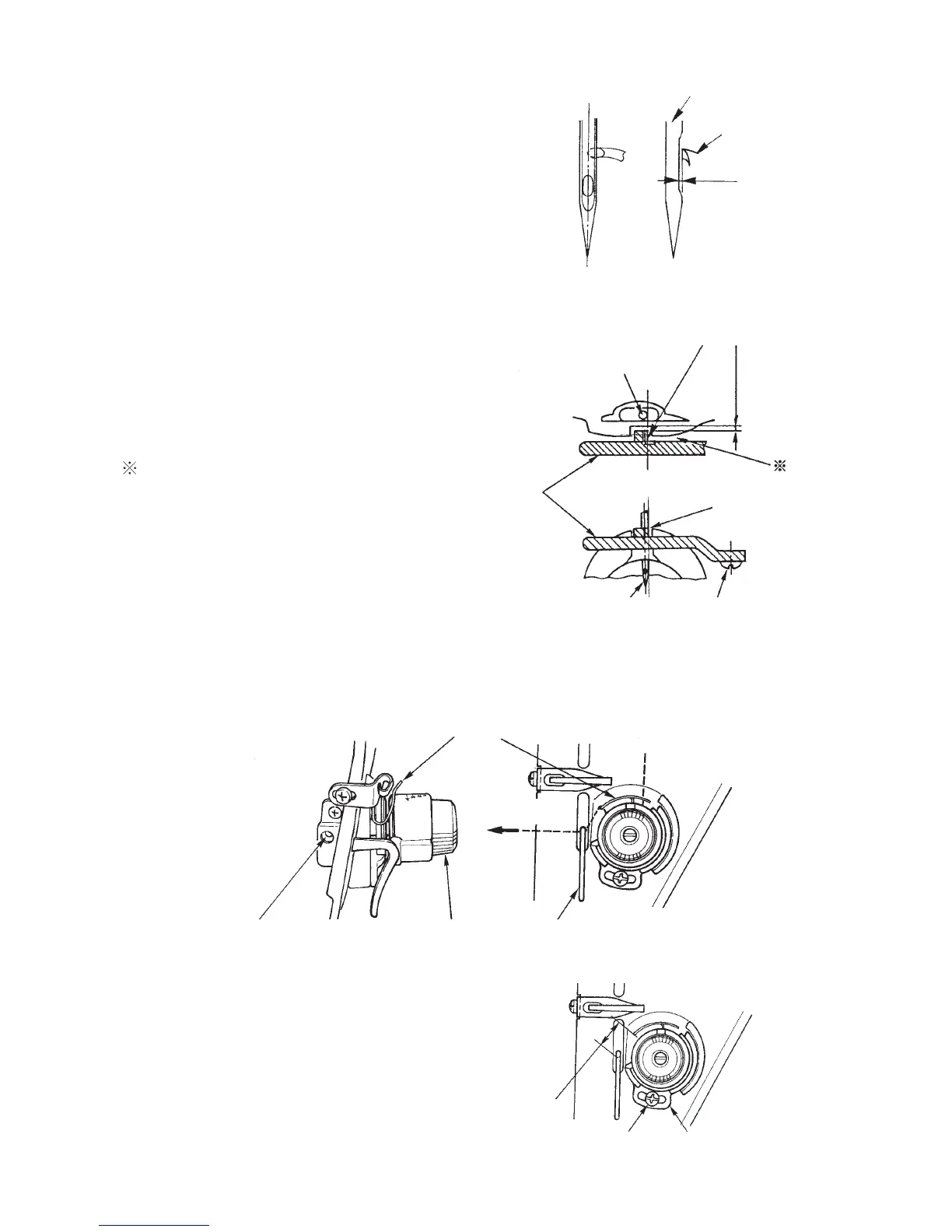

7. Clearance between needle and hook

™ Loosen three setscrews in hook.

™ Align blade point of hook with center of needle.

™ Adjust clearance provided between blade point of

hook and needle to 0.05 to 0.1 mm.

™ Temporarily tighten setscrews, check the timing,

and securely tighten setscrews.

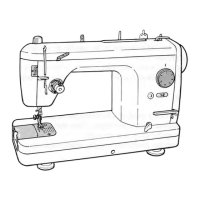

8. Position of bobbin case positioning finger

™

Loosen bobbin case positioning finger setscrew 1.

™ Align right end of convex of bobbin case positioning

finger spring with right end of needle.

™ Temporarily tighten setscrews, hold a clearance of

0.6 to 0.8 mm between inner hook and bobbin case

positioning finger, and securely tighten setscrew

2.

Bobbin case positioning finger should not come in

contact with hook.

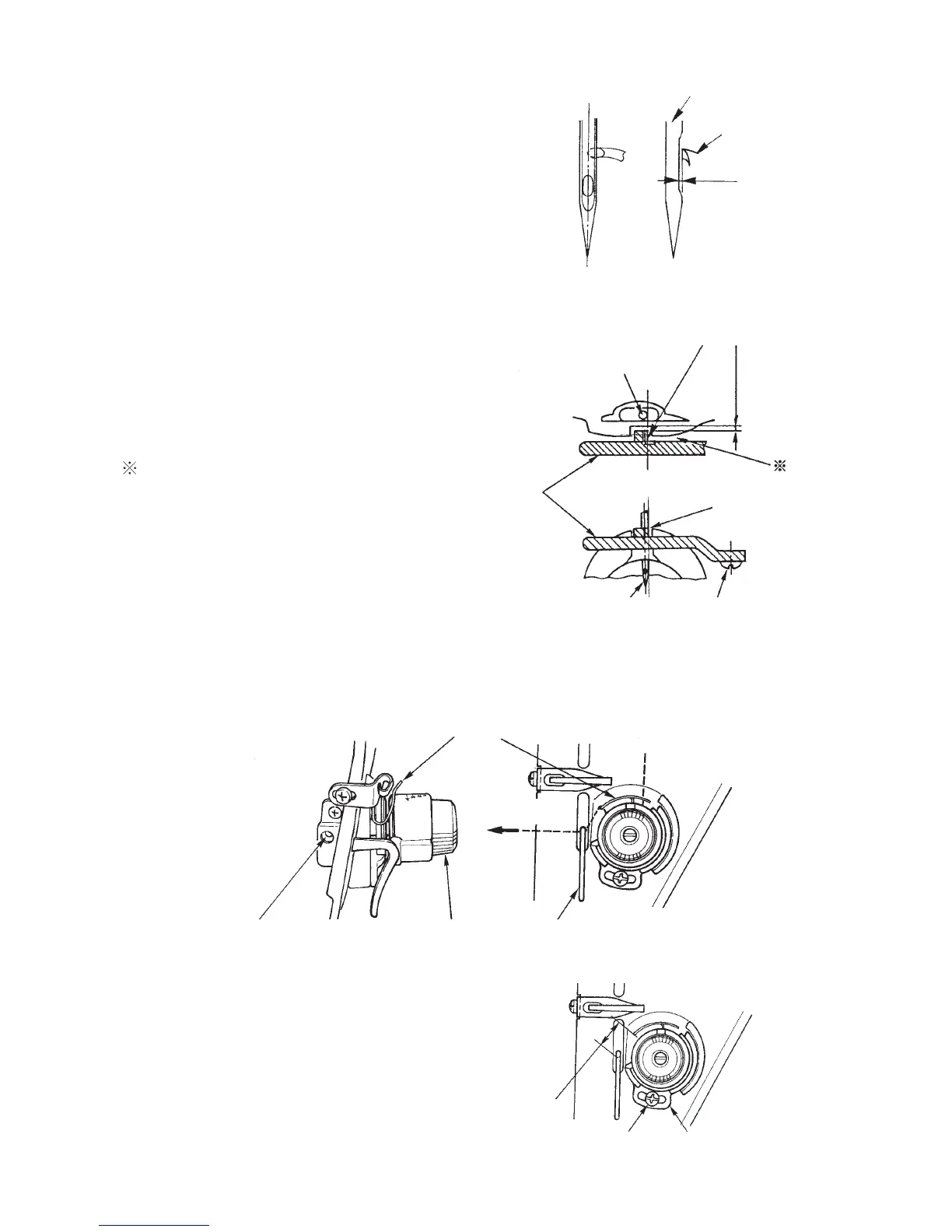

9. Tension of thread take-up spring

™ Pass needle thread up to thread tensioner thread guide 1.

™ Lower presser foot and draw needle thread.

™ Adjust tension of thread take-up spring to 0.127 to 0.157N when thread take-up spring starts lowering.

™ For adjustment, loosen thread tensioner setscrew and turn thread tensioner 3.

™ Turning clockwise = increasing tension of thread take-up spring 4.

10. Momentum of thread take-up spring (absorbing amount of thread)

™ Pass needle thread up to thread take-up and lower

presser foot.

™ Draw needle thread from start of motion of thread

take-up spring to end of its motion.

™ Needle thread is absorbed when it is returned.

Absorbing amount : 10.5±0.5 mm

™ Perform adjustment with thread take-up spring

adjusting plate 1.

0.05 to 0.1 mm

Needle (HA x 1 #14)

Blade point

1 Bobbin case positioning

finger setscrew.

Top view

Bobbin case

positioning

finger

Needle

Front view

Needle

Bobbin case positioning

finger spring

0.6 to 0.8 mm

Align right end of

convex of bobbin case

positioning finger

spring with right end of

needle.

Setscrew

1 Thread take-up spring

adjusting plate.

10.5±0.5 mm

2 Thread tensioner

setscrew

1 Thread tensioner

thread guide

3 Thread tensioner

asm.

4 Thread take-up spring

2

Needle thread

Loading...

Loading...