F 5

1001.GB

a) First check of the wheel nuts after approx. 100 operating hours for tight fit. Re-tighten if

necessary. For starting torque, see maintenance plan.

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

c) 1. exchange after 500 hours of operation / if required, change coarse sieve.

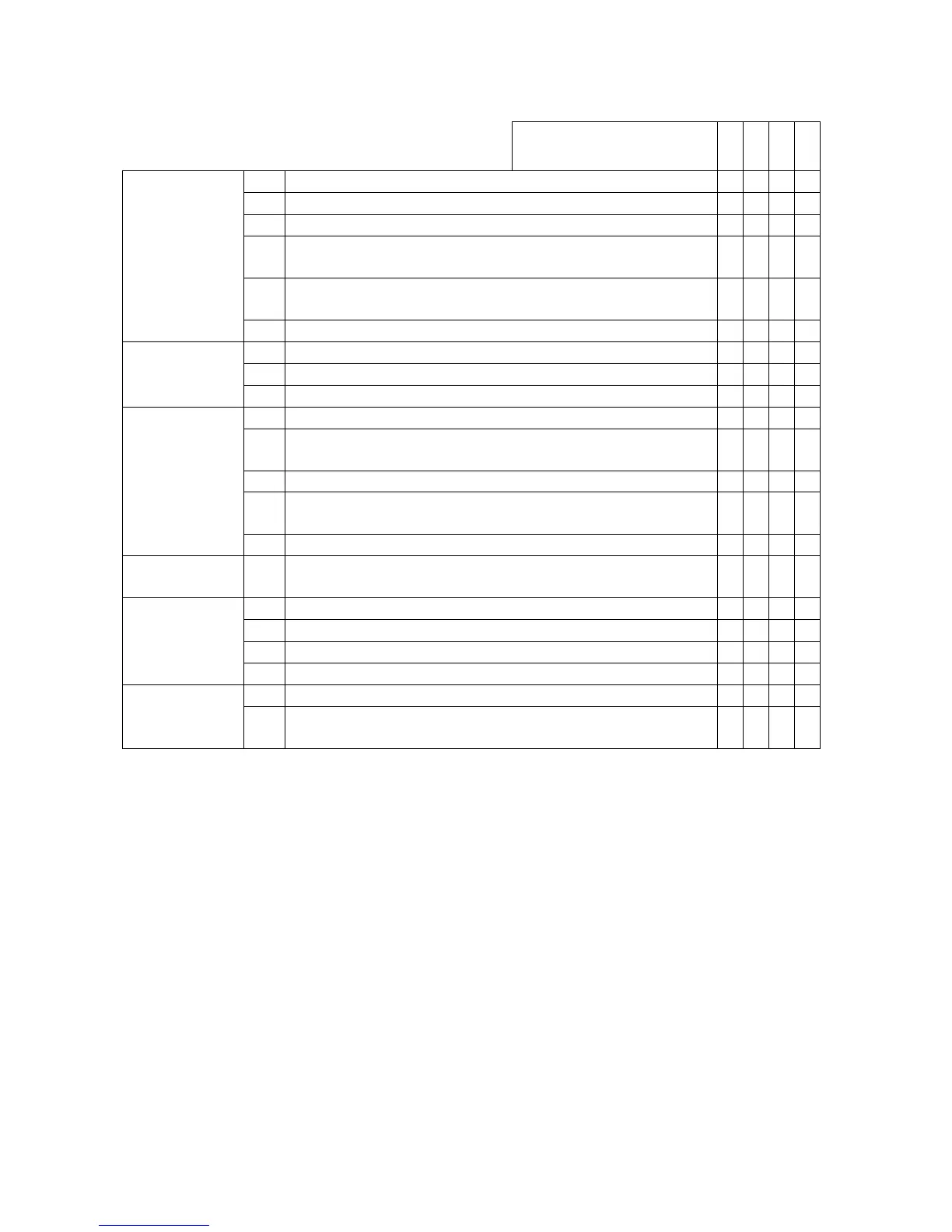

A

The maintenance intervals refer to normal service conditions. If you are working un-

der difficult conditions, reduce the intervals, if required.

Maintenance intervals

Standard = t WMMM

Cold-storage depot = k 13612

Electr.

system:

9.1 Check function t

9.2 Check all cables for secure connection and damage t

9.3 Check the fuses for correct amperage t

9.4 Check switches and trip cams for proper functioning and

seating

t

9.5 Check contactors and relays, replace wearing parts, if

necessary

t

9.6 Check functioning of warning devices and safety circuits kt

Electric

motors:

10.1 Check wear of carbon brushes t

10.2 Check the motor for secure attachment t

10.3 Suck out engine block, check wear of collector kt

Battery: 11.1 Check acid density, acid level and cell voltage lt

11.2 Check the terminals for secure attachment and apply

pole grease

lt

11.3 Clean battery connections, check for tight fit lt

11.4 Check the battery cables for damage and replace, if

necessary

t

11.5 Check the battery lock for proper functioning t

Lubrication

service:

12.1 Grease truck according to lubrication schedule lt

General mea-

surements:

13.1 Check electrical system for short to ground t

13.2 Check driving speed and braking distance t

13.3 Check lifting and lowering speed t

13.4 Check safety facilities and switch-off devices t

Demonstrati-

on:

14.1 Perform a trial run under a nominal load t

14.2 Demonstrate the truck to a person charged with inspec-

tion upon completion of the maintenance of the truck

lt

F 5

1001.GB

a) First check of the wheel nuts after approx. 100 operating hours for tight fit. Re-tighten if

necessary. For starting torque, see maintenance plan.

b) Hydraulic connections to be first checked for leakage after approx. 100 operating hours;

tighten, if necessary.

c) 1. exchange after 500 hours of operation / if required, change coarse sieve.

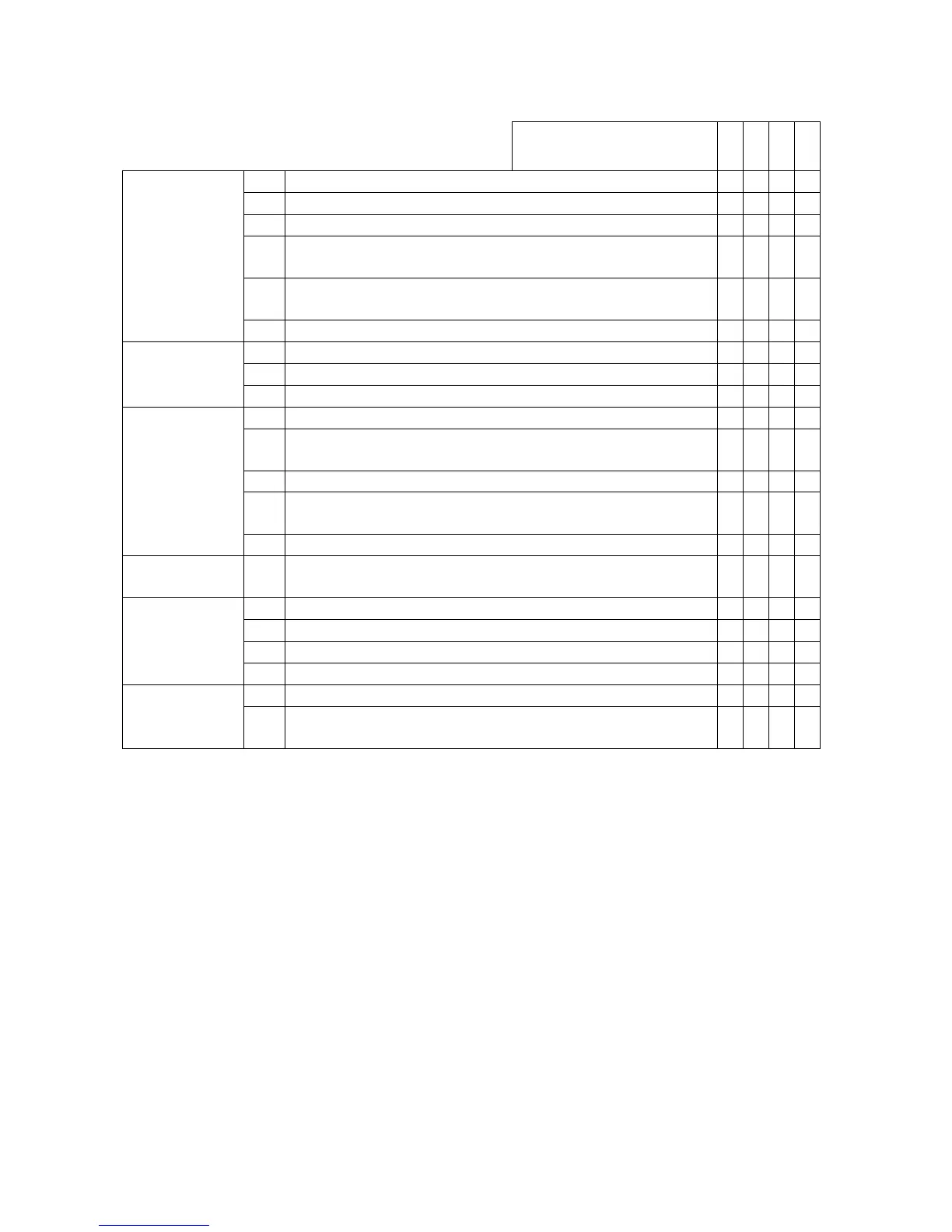

A

The maintenance intervals refer to normal service conditions. If you are working un-

der difficult conditions, reduce the intervals, if required.

Maintenance intervals

Standard = t WMMM

Cold-storage depot = k 13612

Electr.

system:

9.1 Check function t

9.2 Check all cables for secure connection and damage t

9.3 Check the fuses for correct amperage t

9.4 Check switches and trip cams for proper functioning and

seating

t

9.5 Check contactors and relays, replace wearing parts, if

necessary

t

9.6 Check functioning of warning devices and safety circuits kt

Electric

motors:

10.1 Check wear of carbon brushes t

10.2 Check the motor for secure attachment t

10.3 Suck out engine block, check wear of collector kt

Battery: 11.1 Check acid density, acid level and cell voltage lt

11.2 Check the terminals for secure attachment and apply

pole grease

lt

11.3 Clean battery connections, check for tight fit lt

11.4 Check the battery cables for damage and replace, if

necessary

t

11.5 Check the battery lock for proper functioning t

Lubrication

service:

12.1 Grease truck according to lubrication schedule lt

General mea-

surements:

13.1 Check electrical system for short to ground t

13.2 Check driving speed and braking distance t

13.3 Check lifting and lowering speed t

13.4 Check safety facilities and switch-off devices t

Demonstrati-

on:

14.1 Perform a trial run under a nominal load t

14.2 Demonstrate the truck to a person charged with inspec-

tion upon completion of the maintenance of the truck

lt

Loading...

Loading...