TP-6735 7/1764 Section 5 Component Testing and Adjustment

5.5 Slip Rings

Slip rings acquire a glossy brown finish in normal

operation. Do not attempt to maintain a bright,

newly-machined appearance on the slip rings.

Cleaning with a dry, lint-free cloth is usually sufficient.

Use very fine sandpaper (#00) and apply light pressure

to remove roughness. Do not use emery or

carborundum paper or cloth. Clean all carbon dust from

the generator after sanding the slip rings. If the rings are

black or pitted, remove the rotor and use a lathe to

remove some of the s lip ring surface material.

5.6 Brushes

The brushes transfer current to the slip rings. The

brushes should last the life of the generator. However,

abrasive dust on the slip ring can shorten the life of the

brushes.

Excessive arcing at the brushes could damage the

controller. Weak springs, damaged slip rings, sticking

brushes, a loose brush holder, or poor brush contact

causes arcing.

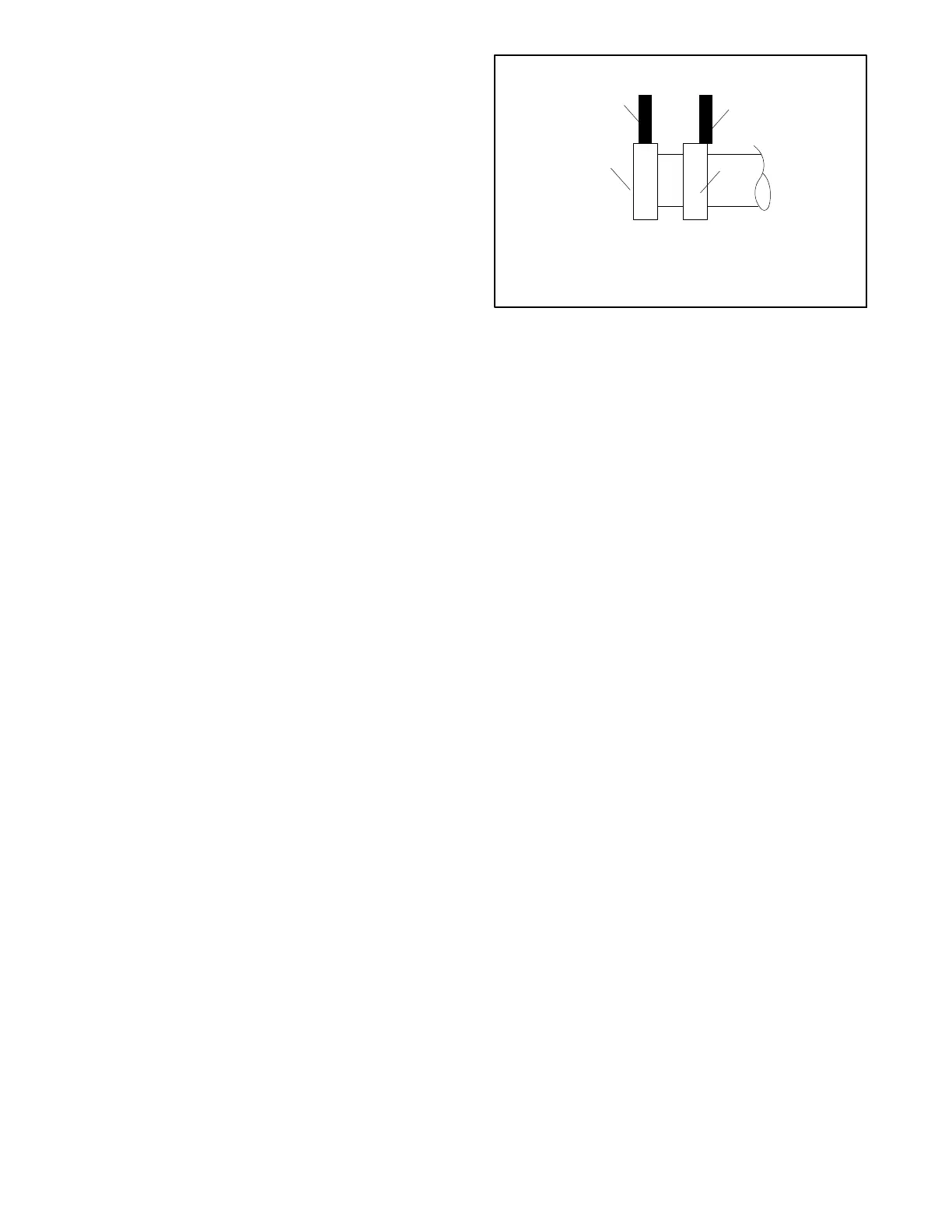

The brush holder assemblies are illustrated in

Figure 5-9 and Figure 5-10. The brushes must be free

to move within the holder and be held in contact with the

slip rings by the springs. When correctly positioned,

spring pressure on the brush surface causes the brush

to wear evenly. The entire brush must ride on the r ing or

arcing occurs and causes burned rings or voltage

regulator failure. Figure 5-8 shows the correct

positioning of the brushes. Add or remove shims as

necessary to center the brushes on the slip rings.

Replace the brushes if they show uneven wear or are

worn to one half their original length.

Check the resistance through the brushes. Resistance

through the brushes should be low, 0.1--0.2 ohms

without meter lead resistance.

1. Correctly positioned brush

2. Incorrectly positioned brush

3. Slip rings

TP5867

Side View

1

2

3

3

Correct Incorrect

Figure 5-8 Brush Position

Loading...

Loading...