TP-5393 9/933-6 Scheduled Maintenance

Spark Plugs

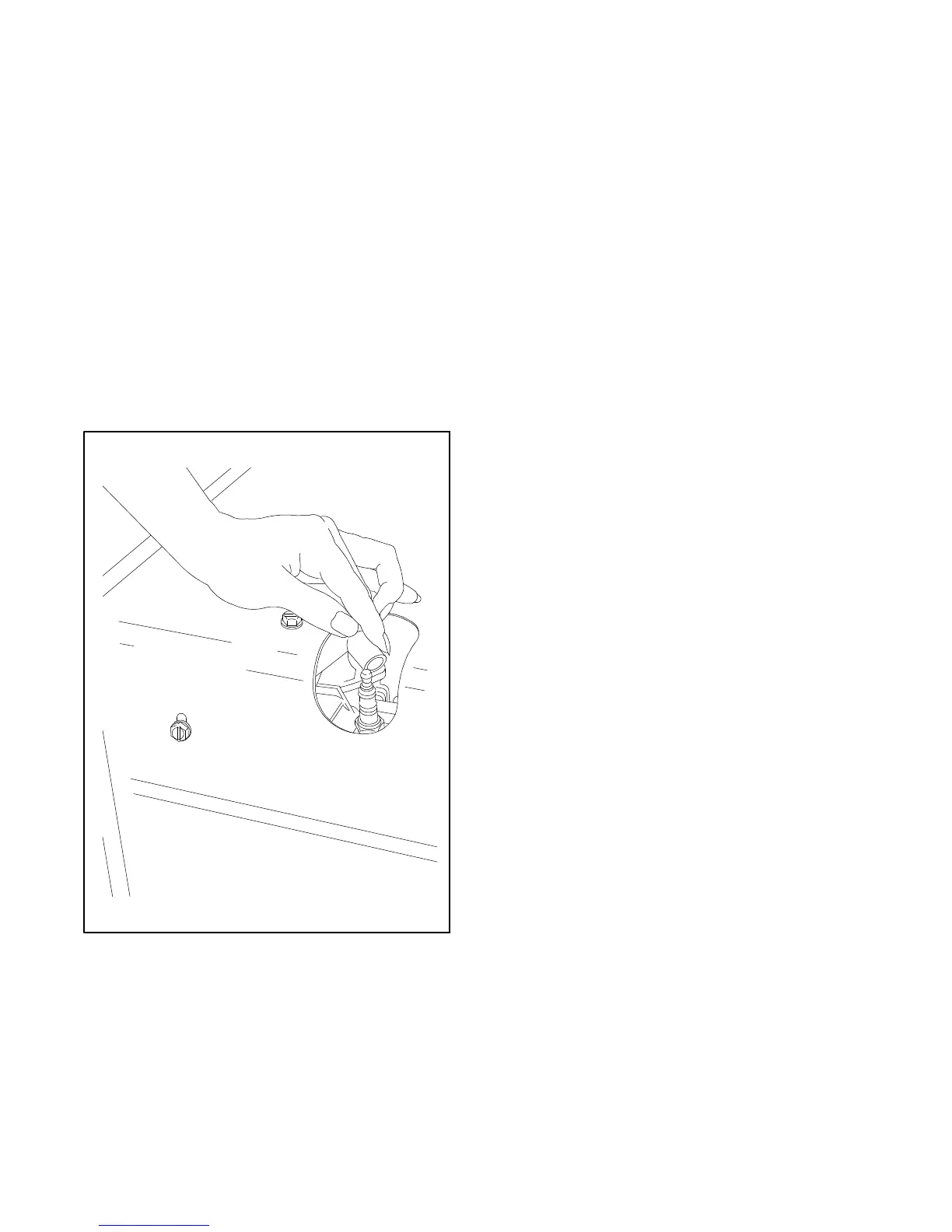

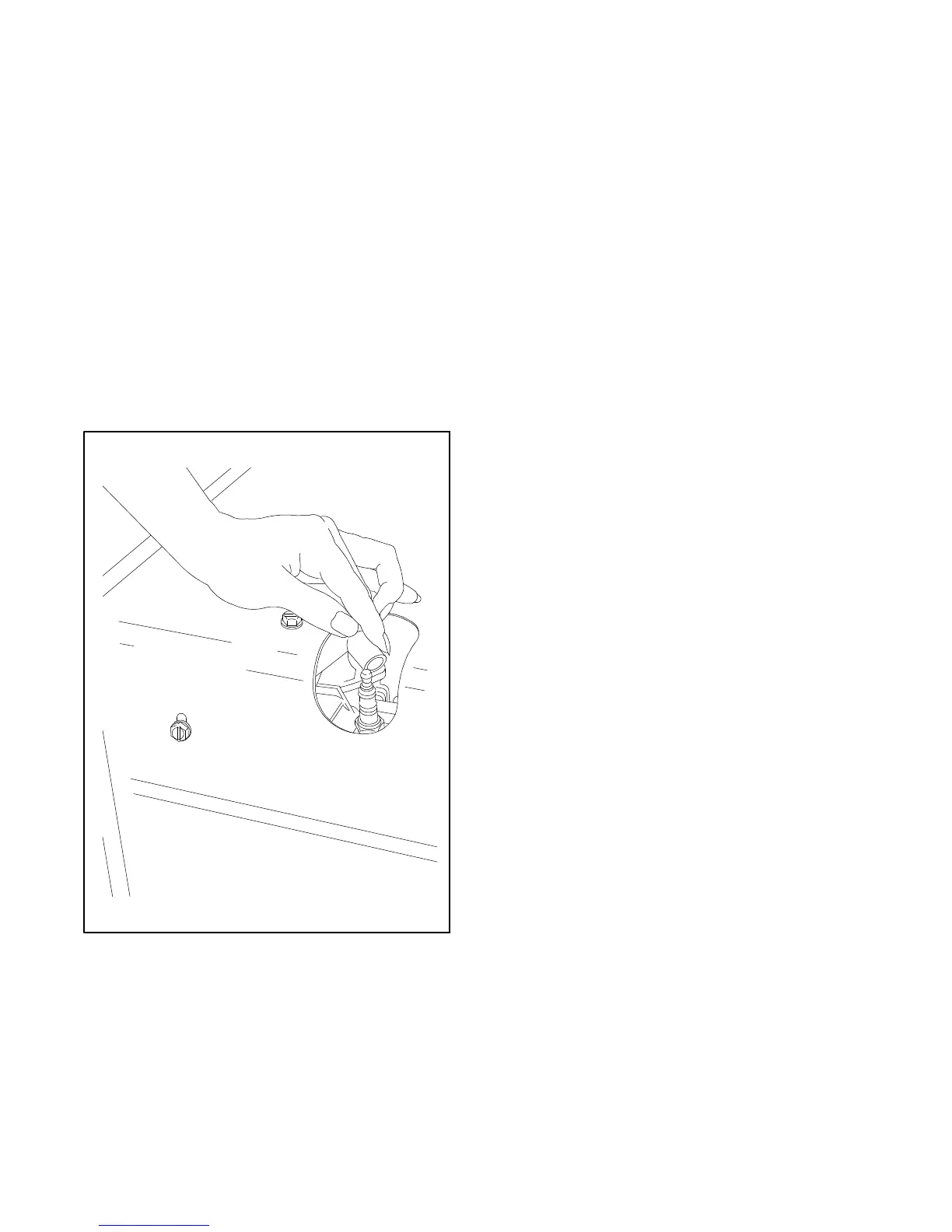

Every 100 hours remove both spark plugs and check

condition (see Figure 3-7). Reset gap or replace plug if

needed. Proper generator operation is indicated by a

lightdepositofgrayortanmaterialonplugelectrodes. A

dead white, blistered coating could indicate

overheating. A black (carbon) coating may indicate an

“overrich” fuel mixture caused by a clogged air cleaner

or improper carburetor adjustment.

NOTE

Do not sandblast, wire brush, scrape, or otherwise

service plug in poor condition—best results are

obtained with a new plug. Use only resistor-type plugs.

Set spark plug gap at 0.025 in. (0.64 mm) on gasoline

fueled sets and 0.018 in (0.46 mm) on LP gas fueled

sets. Tighten plug to 10-15 ft. lbs. (13.6-20) when

installing.

1-905

Figure 3-7. Removing Spark Plug

Gasoline Fuel System

Specification—Gasoline

For best results, use only clean fresh, regular grade

unleaded gasoline with a pump sticker octane rating of

87 or higher in the U.S.A. In countries using the

research rating method, it should be 90 octane

minimum.

Unleaded gasoline is recommended since it leaves

fewer combustion chamber deposits. Regular grade

leaded gasoline may also be used; however, be aware

that the combustion chamber and cylinder head will

require more frequent service. Gasohol containing no

more than 10% ethanol can be used if unleaded

gasoline is unavailable. Never use gasohol containing

more than 10% ethanol or gasoline containing

Methanol. Oil must not be mixed with the fuel.

Usefreshgasolinetoensureitisblendedfortheseason,

and to reduce the possibility of gum deposits forming

which could clog the fuel system. Do not use gasoline

left over from the previous season.

Loading...

Loading...