Disassembly

5162 690 01 Rev. C KohlerEngines.com

Lapping Valves

Reground or new valves must be lapped in, to provide

proper fi t. Use a hand valve grinder with a suction cup

for fi nal lapping. Lightly coat valve face with a fi ne grade

of grinding compound, then rotate valve on its seat with

grinder. Continue grinding until a smooth surface is

obtained on seat and on valve face. Thoroughly clean

cylinder head in soap and hot water to remove all traces

of grinding compound. After drying cylinder head, apply

a light coating of SAE 10 oil to prevent rusting.

Valve Stem Seals

These engines use valve stem seals on intake and

exhaust valves. Always use new seals when valves

are removed from cylinder head. Seals should also be

replaced if deteriorated or damaged in any way. Never

reuse an old seal.

Remove Breather Assembly

1. Remove four fasteners securing breather assembly,

breather adapter (style based on spec), and gaskets

to crankcase.

2. Carefully break gasket seals and remove all parts.

Do not pry on sealing surfaces as it could cause

damage resulting in leaks. Note assembly and

orientation of parts.

Remove Oil Reservoir and Pickup Screen

1. Remove eight screws securing oil reservoir and

gasket to engine.

2. Remove mounting screw and carefully work pickup

screen off end of pickup tube.

Remove Closure Plate Assembly

1. Remove fourteen hex fl ange screws securing

closure plate to crankcase.

2. Locate two protruding tabs on closure plate.

Carefully tap to break gasket seal. Do not pry on

sealing surfaces as this could cause leaks. Separate

closure plate from crankcase. Remove old gasket.

Inspection

Inspect oil seal in closure plate and remove it if it is worn

or damaged.

Inspect main bearing surface for wear or damage.

Replace bearing or closure plate assembly if required.

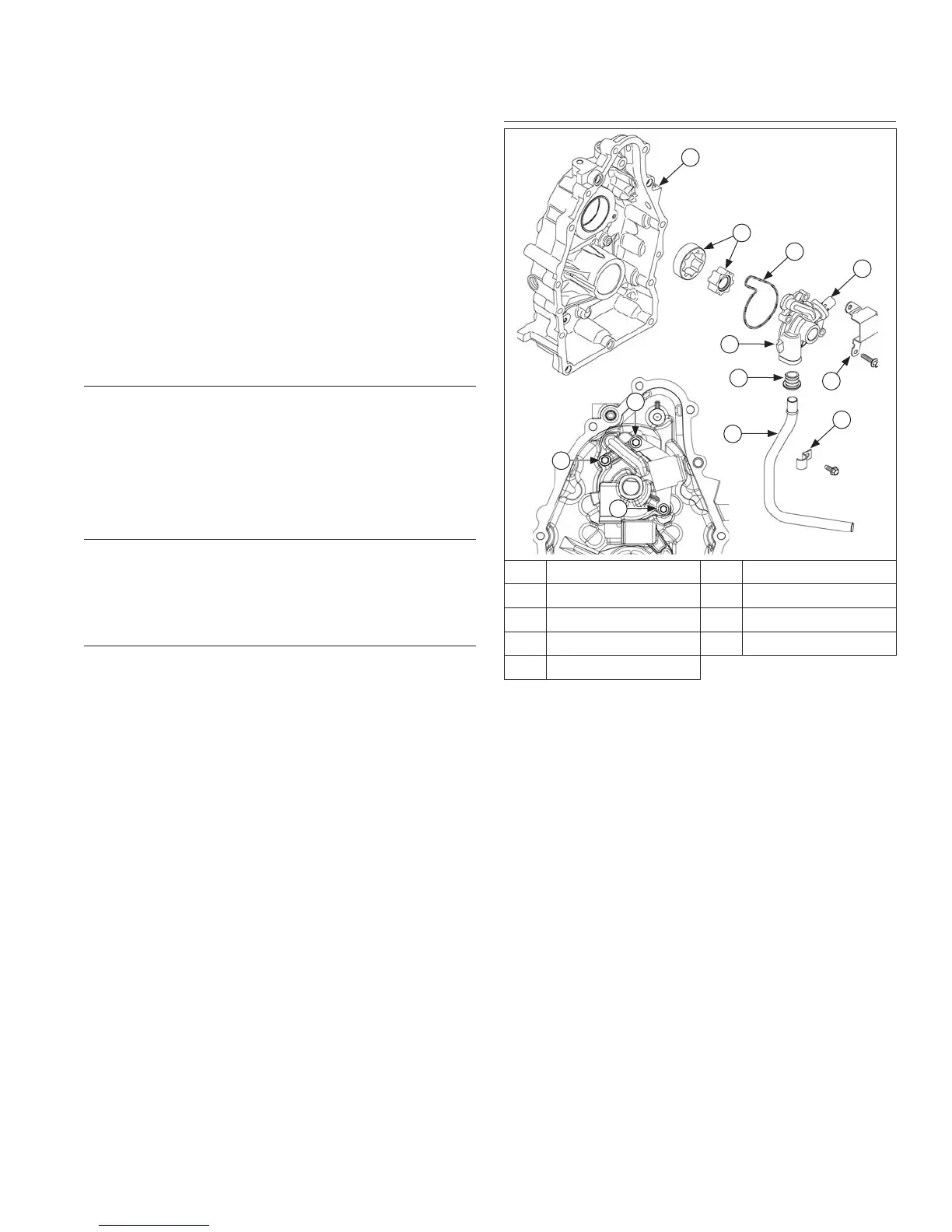

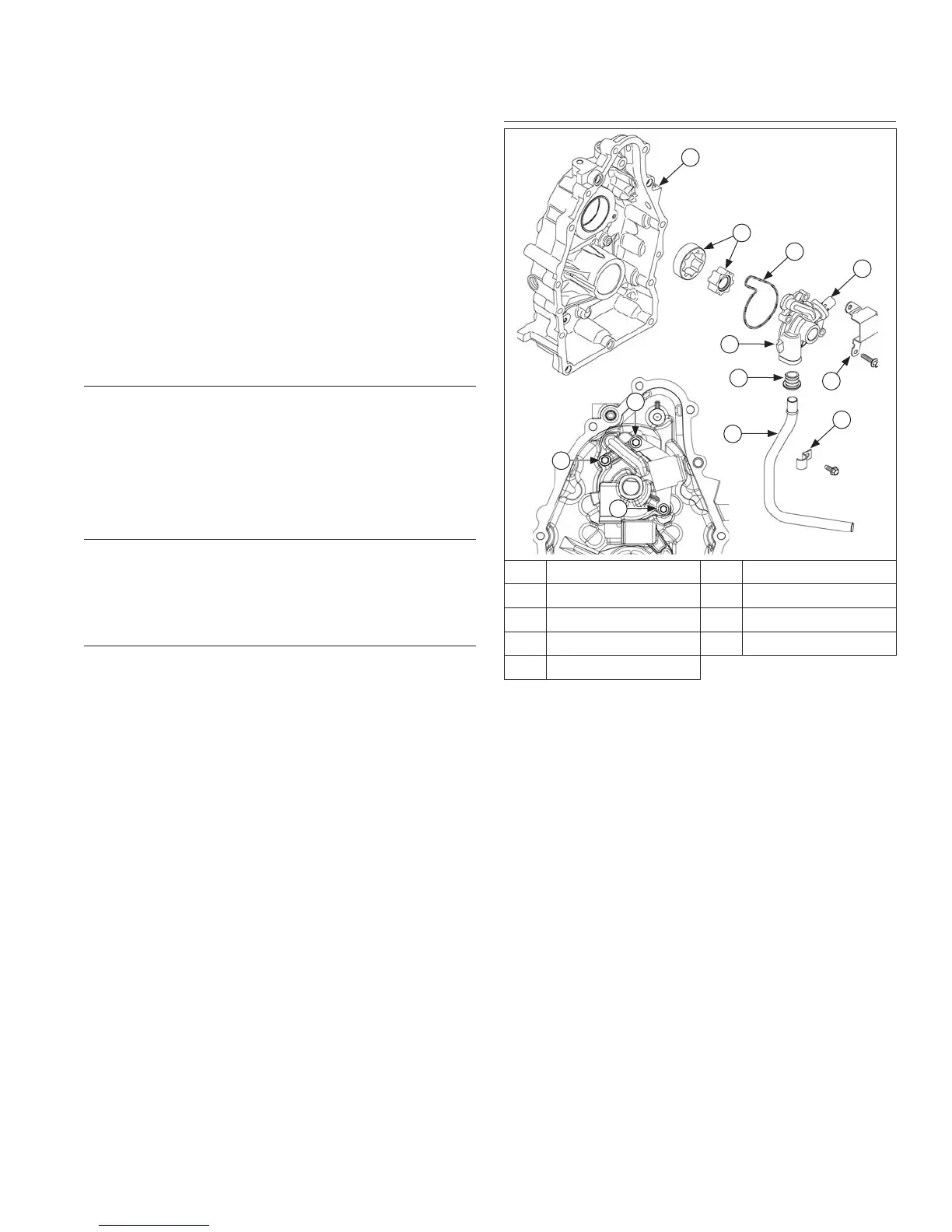

Oil Pump Assembly

A

B

C

D

F

E

H

G

3

2

1

I

A Closure Plate B Gerotor Gears

C Oil Ring D Relief Valve

E Oil Pump F Inlet Seal

G Relief Valve Baffl e H Clamp

I Pickup Tube

Disassembly

1. Remove three hex fl ange screws securing oil pump

housing including relief valve baffl e, and single

screw with clamp for pickup tube.

2. Remove oil pump housing and pickup tube from

closure plate.

3. Remove oil pump gerotor gears from closure plate

recess.

4. Remove oil pickup by pulling it free from oil pump

body.

5. Relief valve is a one-piece style, staked to oil pump

housing; removal should not be attempted, nor is

internal servicing possible. If a problem with relief

valve is encountered, oil pump should be replaced.

Inspection

Inspect oil pump housing, gerotor gears, and closure

plate recess for nicks, burrs, wear, or any visible

damage. Inspect inlet seal for pickup tube in housing. If

any parts are worn or damaged, replace seal, oil pump

or closure plate as required.

Loading...

Loading...