62

Reassembly

KohlerEngines.com 62 690 01 Rev. C

Install Outer Cylinder Baffl es

1. Install outer cylinder baffl es. Make sure spark plug

lead is routed through corresponding opening in

each baffl e. Start each screw. Tighten M6 shoulder

screws going through backing shroud assembly into

extruded holes in baffl es to torque specifi cations.

Tighten M6 screws going into cylinder head and

crankcase to torque specifi cations.

Install Oil Cooler

1. Connect two hoses between oil fi lter adapter and oil

cooler. Secure with new clamps.

2. Align oil cooler with bosses in backing shroud

assembly. Secure with two screws and washers.

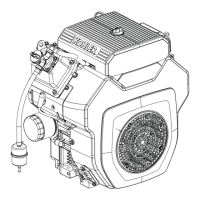

Install Cooling Fan and Grass Screen

F

E

D

C

B

A

A Special Washers B Stiffener

C Fan Screws D Fan

E Mounting Studs F Grass Screen

CAUTION

Failure to utilize or reassemble grass screen as

designed could result in grass screen failure and serious

personal injury.

1. Position cooling fan onto fl ywheel aligning mounting

locations. Apply a small amount of Loctite

®

243™

Threadlocker to threads and install three long

mounting screws. Tighten screws to torque

specifi cation.

2. Apply a small amount of Loctite

®

243™ Threadlocker

to external threaded section, (unless new parts with

preapplied locking compound are being used).

Thread four grass screen hex studs into mounting

holes in fl ywheel. Tighten each stud to torque

specifi cation.

3. Install stiffener followed by metal grass screen onto

four hex studs. Secure with four special washers and

mounting screws using Loctite

®

243™ Threadlocker

on threads. Tighten screws to torque specifi cation.

Install Electric Starter

1. Install electric starter motor using two hex fl ange

screws.

2. Tighten hex fl ange screws to torque specifi cation.

3. Connect leads to solenoid.

Install Flywheel

WARNING: Damaging Crankshaft and Flywheel Can

Cause Personal Injury!

Using improper procedures to install fl ywheel can

crack or damage crankshaft and/or fl ywheel. This not

only causes extensive engine damage, but can also

cause personal injury, since broken fragments could be

thrown from engine. Always observe and use following

precautions and procedures when installing fl ywheel.

NOTE: Before installing fl ywheel make sure crankshaft

taper and fl ywheel hub are clean, dry, and

completely free of any lubricants. Presence of

lubricants can cause fl ywheel to be over

stressed and damaged when hex fl ange screw

is torqued to specifi cations.

NOTE: Make sure fl ywheel key is installed properly in

keyway. Flywheel can become cracked or

damaged if key is not properly installed.

1. Install woodruff key into crankshaft keyway. Make

sure key is properly seated and parallel with shaft

taper.

2. Install fl ywheel onto crankshaft, being careful not to

shift woodruff key.

3. Install hex fl ange screw and washer.

4. Use a fl ywheel strap wrench or holding tool to hold

fl ywheel. Tighten hex fl ange screw to torque

specifi cation.

Install Ignition Modules

1. Rotate fl ywheel to position magnet away from

ignition module bosses.

2. Connect ground lead to single kill tab and install

modules onto crankcase bosses so tab is away from

you (in). Spark plug lead should be towards you

(out). Mount wiring harness clamp with loop up, on

starter (No. 1) side inner module screw and route

harness through it. Attach rectifi er-regulator ground

lead to outer screw.

3. Slide modules up as far away from fl ywheel as

possible and snug screws to hold them in position.

4. Rotate fl ywheel to position magnet directly under

one ignition module.

5. Insert a 0.30 mm (0.012 in.) fl at feeler gauge

between magnet and ignition module. Loosen

screws enough to allow magnet to pull module down

against feeler gauge.

6. Tighten screws to torque specifi cation.

7. Repeat Steps 4 through 6 for other ignition module.

8. Rotate fl ywheel back and forth, checking for

clearance between magnet and ignition modules.

Make sure magnet does not strike modules. Check

gap with a feeler gauge and readjust if necessary.

Final Air Gap: 0.280/0.330 mm (0.011/0.013 in.).

9. Make sure leads are under molded clip on starter

side.

Loading...

Loading...