FUEL

PUMPS

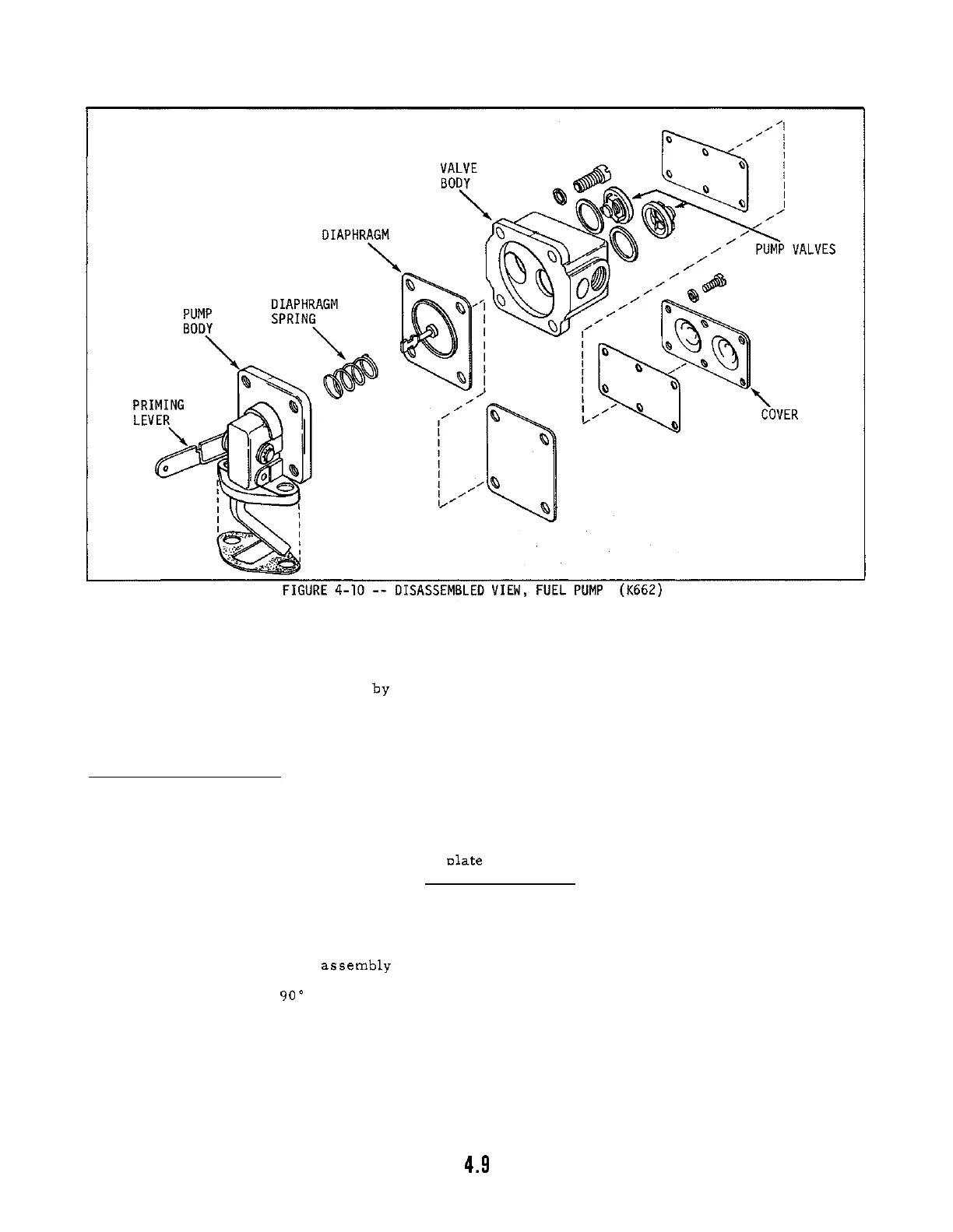

All Kohler Two Cylinder Engines have a mounting pad and provision on top of crankcase for a

mechanically operated fuel pump. Mechanical fuel pumps are furnished by Kohler

--

certain applications

use pulse pumps which are furnished

by the equipment manufacturer.

The mechanical pump operates

off a cam on the camshaft. The fuel pump lever rides on the cam and transmits this mechanical action

to a diaphragm within the pump body.

Most mechanical pumps have an external lever for priming.

Repair kits are available for reconditioning fuel pumps.

Reconditioning Procedure

1.

Remove fuel lines and mounting screws holding pump to engine.

2.

With a file, make an indicating mark across a point at the union of fuel pump body and

cover.

This

is

a positive marking to assure proper reassembly.

Remove assembly

screws and remove cover.

3.

Turn cover over and remove valve date screw and washer. Remove valve retainer, valves,

valve springs and valve gasket, noting their position.

Discard valve springs, valves and

valve retainer gasket.

4.

Clean fuel head thoroughly with solvent and a fine wire brush.

5.

Holding pump cover with diaphragm surface up, place new valve gasket into the cavity.

Now assemble the valve spring and valves into the cavity and reassemble valve retainer

and lock in position by inserting and ti

g

htening fuel pump valve retainer screw.

6.

Place pump cover assembly in a clean place and rebuild the lower diaphragm section.

7.

Holding mounting bracket, press down on the diaphragm to compress spring under it, then

turn bracket

90' to unhook diaphragm so it can be removed.

8.

Clean mounting bracket with a solvent and a fine wire brush.

9.

Replace the diaphragm operating spring,

stand new spring in casting, position diaphragm

and press down on diaphragm to compress spring and turn

it

90

"

to reconnect diaphragm.

10.

Hold mounting bracket, then place the pump cover on it (make sure that indicating marks

are in line) and insert the screws. DO NOT TIGHTEN.

With the hand on the mounting

bracket only, push the pump lever to the limit of its travel and hold in this position while

tightening the four screws.

This

is

important to prevent stretching the diaphragm.

11. Mount the fuel pump on engine, using the new mounting gaskets.

Reconnect the fuel lines.