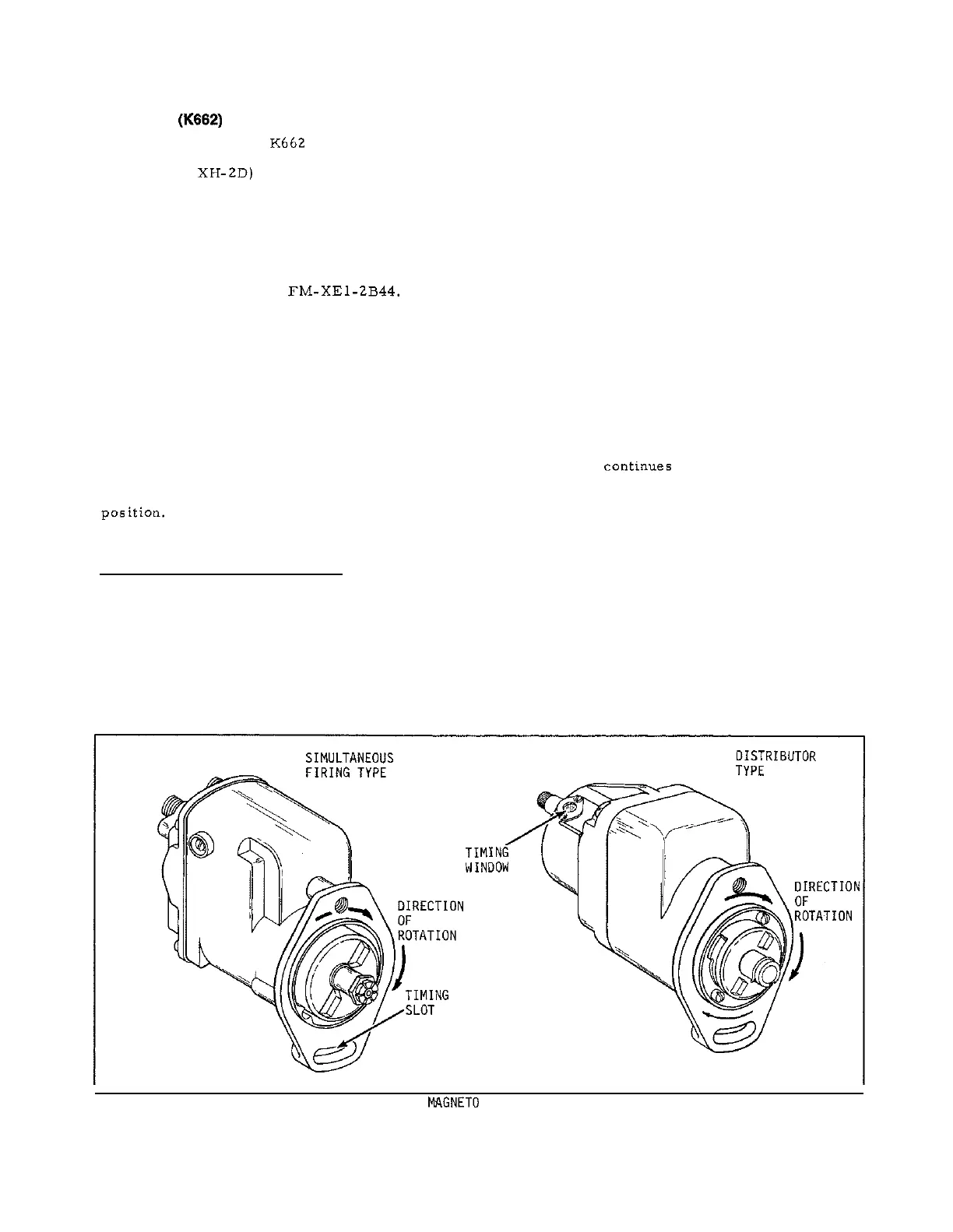

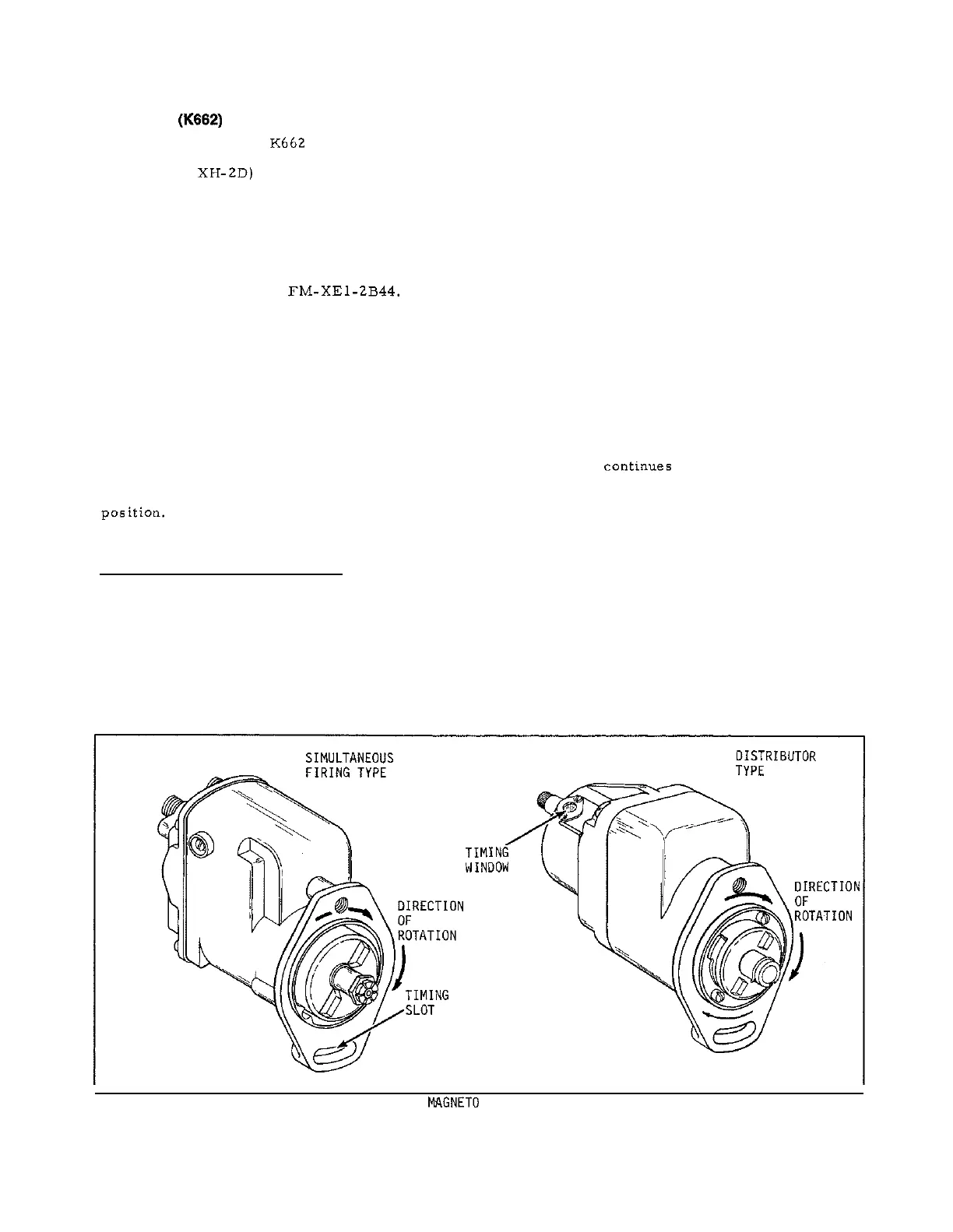

MAGNETO

(K662)

Magnetos on the K662 are external, self contained units which are flange mounted on the gear

housing and driven off the cam gear. Two basic types of magnetos are used.

The standard magneto

(Wico Model

XH-2D) is referred to as a simultaneous firing magneto.

A

special radio shielded simul

-

taneous firing magneto is also used.

This type fires both spark plugs at the same instant.

Ignition

occurs only in the cylinder in which the piston is at the ignition point

--

the spark in the other cylinder

is ineffective since this occurs on the exhaust stroke.

The other magneto is classified as a distributor type magneto.

This has a built in distributor

rotor which switches or directs the ignition voltage to the proper spark plug at the appropriate time.

Two different distributor magnetos are used. One is the Wico Model XHG

-

2 and the other is the

Fairbanks

-

Morse Model FM-XE1-2B44. The Fairbanks

-

Morse

is

a radio shielded magneto which is

used mainly on electric plant applications where any high frequency emission must be suppressed or

contained. Since the service and timing procedure varies for each magneto, each is covered separately

in this manual. Special tools and test equipment are required to properly recondition magnetos. This

work should therefore be done only at a qualified magneto repair station.

Most magnetos use impulse couplings which function to intensify the ignition spark at low speeds

to facilitate starting. The impulse coupling functions as a mechanical reservoir to store energy.

Basically the impulse coupling consists of a shell and a hub connected together by a strong spring.

One half of the coupling (the shell) is fitted to a drive member on the engine drive shaft. while the

other half (the hub) is keyed to the magneto rotor shaft. In operation at slow speeds, a pawl on the

magneto half of the coupling engages a stop pin mounted on the magneto frame which acts to prevent

further movement of the rotor while the engine half of the coupling

cont~nues to rotate.

The relative

change in position winds the connecting spring.

When ignition spark is required, the pawl is released

and the drive spring permitted to snap the magneto rotor forward at high speed through its firing

~osition.

As the speed of the engine picks up, the centrifugal force acting on the pawls withdraws

them in a position where they no longer engage the coupling stop pin and the impulse coupling then acts

as a solid drive member.

Standard Magneto (Wico XH

-

ZD):

After every

500

hours of operation, remove end cap and lubricate

cam wick with Rycon grease then check condition of breaker contacts. If dirty, clean with solvent

such as lacquer thinner and a coarse cloth.

If a slight amount of metal transfer or pitting is noted,

dress contacts with either a small tungsten file or a fine stone. Contact point gap must be readjusted

after replacement or performance of any service on contacts.

Use

following procedure to adjust:

1.

Turn engine over by hand until points are wide open (at highest point on cam).

2.

Loosen the two clamp screws until contact plate can be moved.

3.

Insert blade of screwdriver in adjusting slot and move plate until

.

015

"

maximum clearance

is measured (feeler gauge) between contacts. After proper gap is attained, securely tighten

clamp screws to lock plate at this setting.

I

I

FIGURE

6

-

2

--

FWGNETO

TYPES

-

-

K662

ENGINE

6.3

Loading...

Loading...