IGNITION

SYSTEMS

While the source of energy for the ignition system may be either magnetc or battery (generator

or alternator), most other components are common in function in all systems even though they may not

be alike in appearance or location.

When checking out an ignition system, start with the components that require most frequent

ser

-

vice

or

adjustment. Hard starting, roughness, low power and erratic operation are often attributed to

faulty ignition. All components must be in top condition and the ignition spark must be properly timed

to maintain good performance.

SPARK PLUG

Engine misfire or generally poor operation is often caused by spark plugs in poor condition or

with improper gap setting. Always clean area around spark plugs before removing to prevent dirt

from falling into engine.

The first thing to do after removing a spark plug is to carefully note its con

-

dition as this is often an indicator of the ignition trouble. Plugs fail for various reasons. Often the

porcelain insulator cracks or becomes coated with oil, carbon or other deposits. This can cause the

high voltage ignition impulse to pass from the center electrode to ground without jumping the spark gap.

As an engine operates, the electrodes are gradually burned or worn away.

In time,

the gap becomes

so wide that the available ignition voltage cannot jump the gap and the engine misses.

Spark Plug Service:

Every 100 hours remove plug, check condition and reset gap. Good operating con

-

ditions are indicated if plug has light coating of gray or tan deposit. A dead white, blistered coating

could indicate overheating.

A

black (carbon) coating may indicate an "overrich" fuel mixture caused

by clogged air cleaner or improper carburetor adjustment. Do not sandblast, wire brush, scrape or

otherwise service plug in poor condition

--

best results are obtained with new plug.

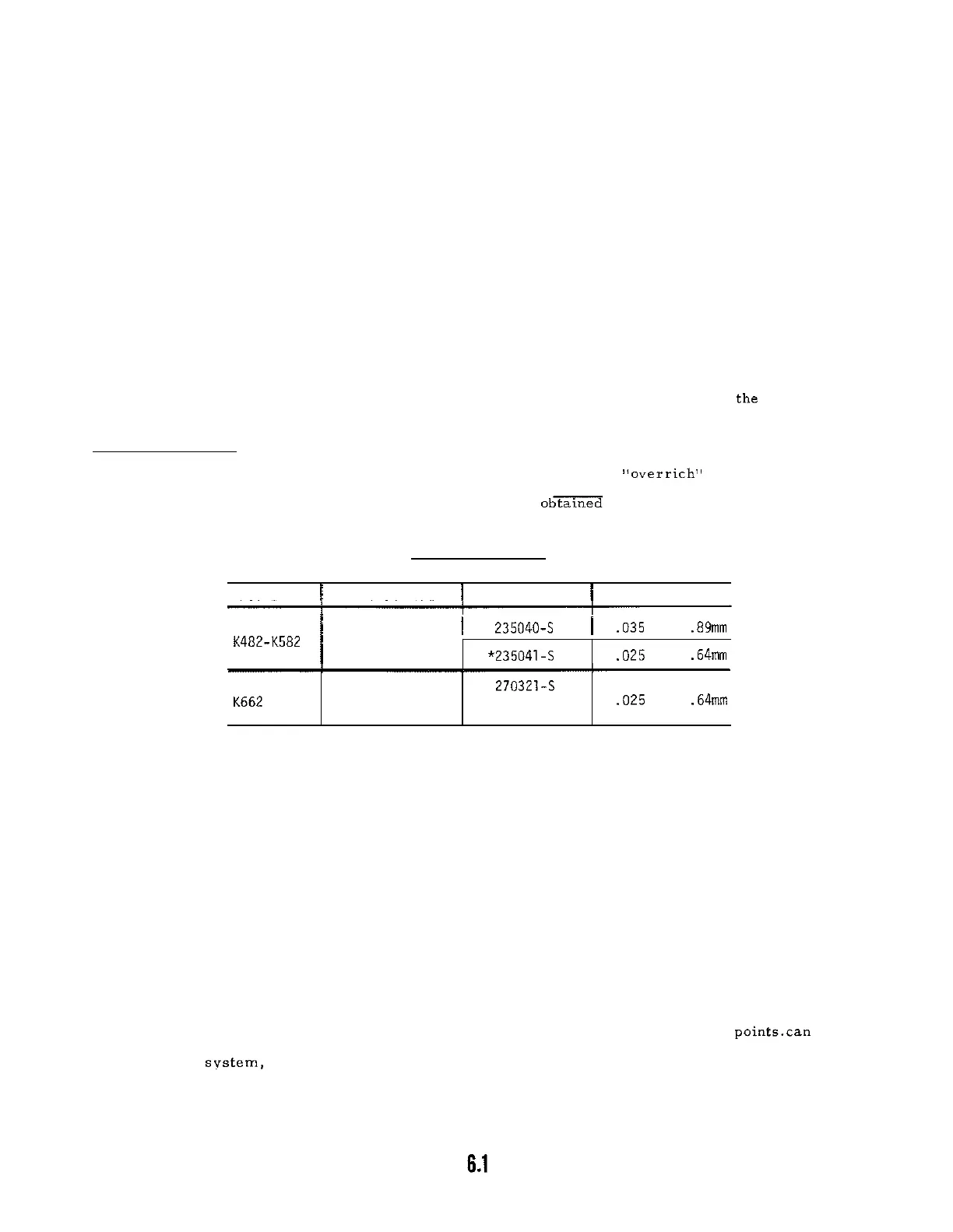

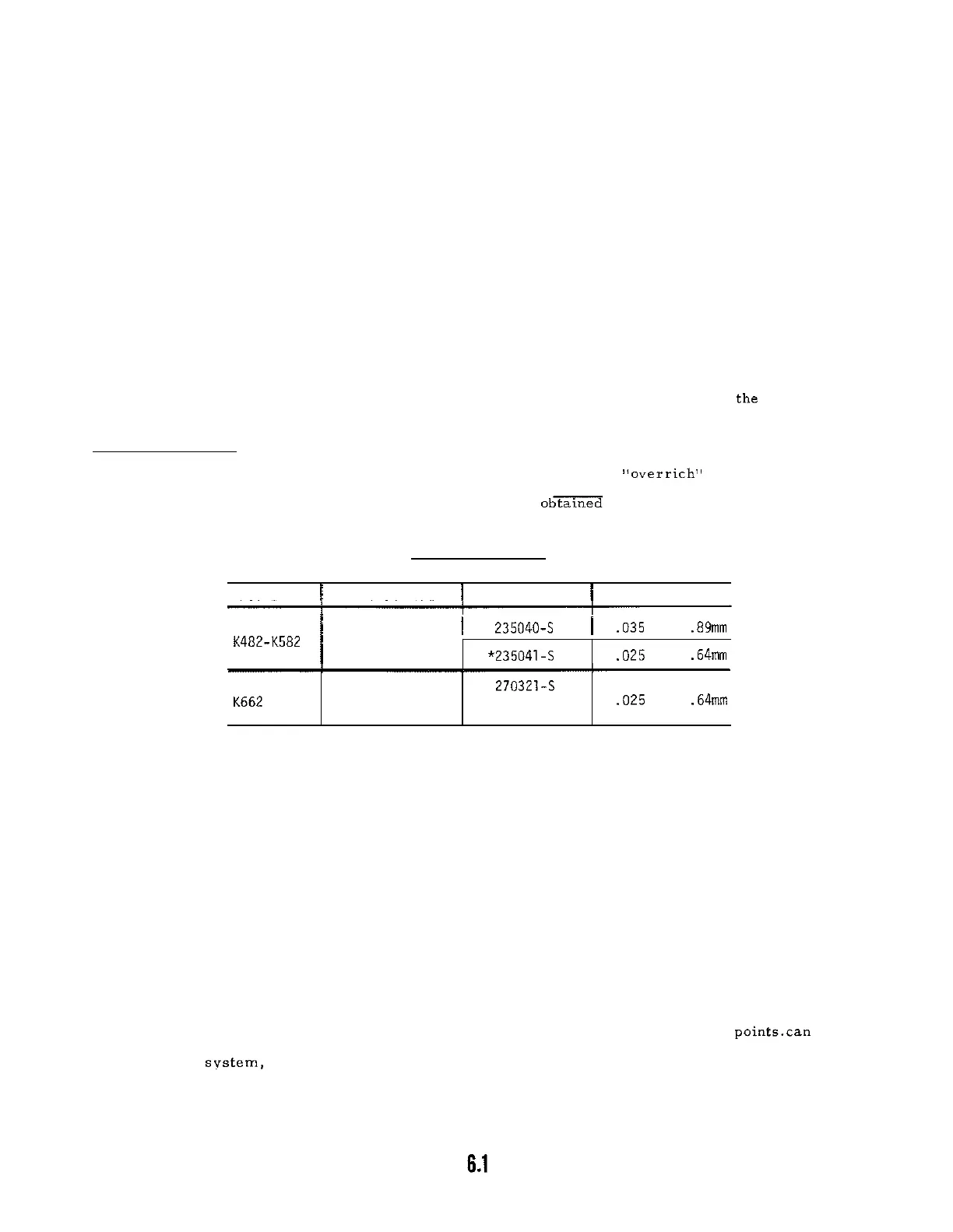

SPARK PLUG DETAILS

MODEL

/

IGNITION TYPE

I

PART NO.

1

GAP

1 1

235040-8

1

,035

in.

.89mrn

K482-K582

/

Battery

"

Standard resistor

plug.

BREAKER POINTS

K662

Engine operation is greatly affected by breaker point condition and adjustment of the gap.

If

points are burned or badly oxidized, little or no current will pass and as a result the engine may not

operate at all, or if it does run it is likely to miss particularly at full throttle.

Adjusting breaker

point gap affects the time that the contacts are opened and closed.

If

the points are adjusted to a wider

gap, they will open earlier and close later in terms of cam movement. A definite time is required for

the magnetic field within the ignition coil to build up to sufficient value. If the contact points are

closed for too short a time, a weak spark will be produced by the coil.

If points are set too wide, they

will open before the primary current reaches the maximum value and on the other hand if set too close,

they will open after the primary current has passed its maximum value.

I

Always replace badly burned or pitted breaker points.

A certain amount of build up or metal

transfer occurs under normal operating conditions; however, if this occurs too frequently and becomes

excessive, the condenser may be at fault

--

see Condenser Service for details. Slightly pitted points

can he dressed down with a point file, although this should be done only as a temporary field fix since

points may tend to arc more readily after filing. Replace points at first opportunity after filing.

If the

points are oxidized, rub a piece of coarse cloth between the surfaces.

Dirty or oily

points.can be

cleaned with cloth but make sure no particles of lint are left between surfaces. On engines equipped with

the Alternator

svstem, the breaker points are externally mounted on the governor and operated off

a

cam on the governor driveshaft.

On engines with the external unit magnetos, the breaker points are

located inside the magneto.

Refer to Magneto or Alternator headings (depending on type used on the

engine) in this section for specific details on breaker points or contacts.

*235041-S

Magneto

,025

in.

.64mm

270321-5

*41 132 06

,025

in.

.64mm

Loading...

Loading...