LUBRICATION

The 2 cylinder engines have positive pressure gear type oil

pumps which supply oil through inter

-

nal galleys to main bearing, camshaft bearing, connecting rod and other wear areas.

On

K662 models,

transfer sleeves are used to direct oil to the anti

-

friction type main bearings. On some early K482

engines, oil

is picked up through a floatinq oil screen

-

-

a fixed oil screen is used on most K482 and

K532, K662 models.

-

-

OIL LEVEL

The lubricating oil level must be maintained in the ''safe

"

operating range at all times.

Oil

level

must be between the L (low) and F (full) marks on the dipstick.

Always clean area around dipstick so

that dirt does not fall into engine when dipstick is removed. Check daily and add oil as necessary to

maintain proper level

--

DO NOT OVERFILL

--

oil level must not exceed the F mark.

There are several different types of dipsticks in use. On the shorter type, which consists of a

combined dipstick

-

oil

fill

plug, turn plug all the way out of crankcase, remove and wipe oil off dipstick

then reinsert

-

-

shoulder plug on top of hole (do not turn plug in) before removing for reading.

With the

extended oil

fill

tube and bayonette type dipstick, push or twist cap until dipstick is all the way down

on tube, then remove and take reading.

Check gasket (or

ring) inside cap occasionally to make sure

it

is clean and in good condition.

CAUTION:

New

engines are usually shipped from factory with dry sump

--

check to make sure proper amount

in the engine or added before engine is started for the first time.

(Also add oil as needed

to driven equipment such as wet type clutch.)

OIL

TYPE

use

high

-

quality detergent oil of API (American Petroleum Institute) Service Class SF.

Select

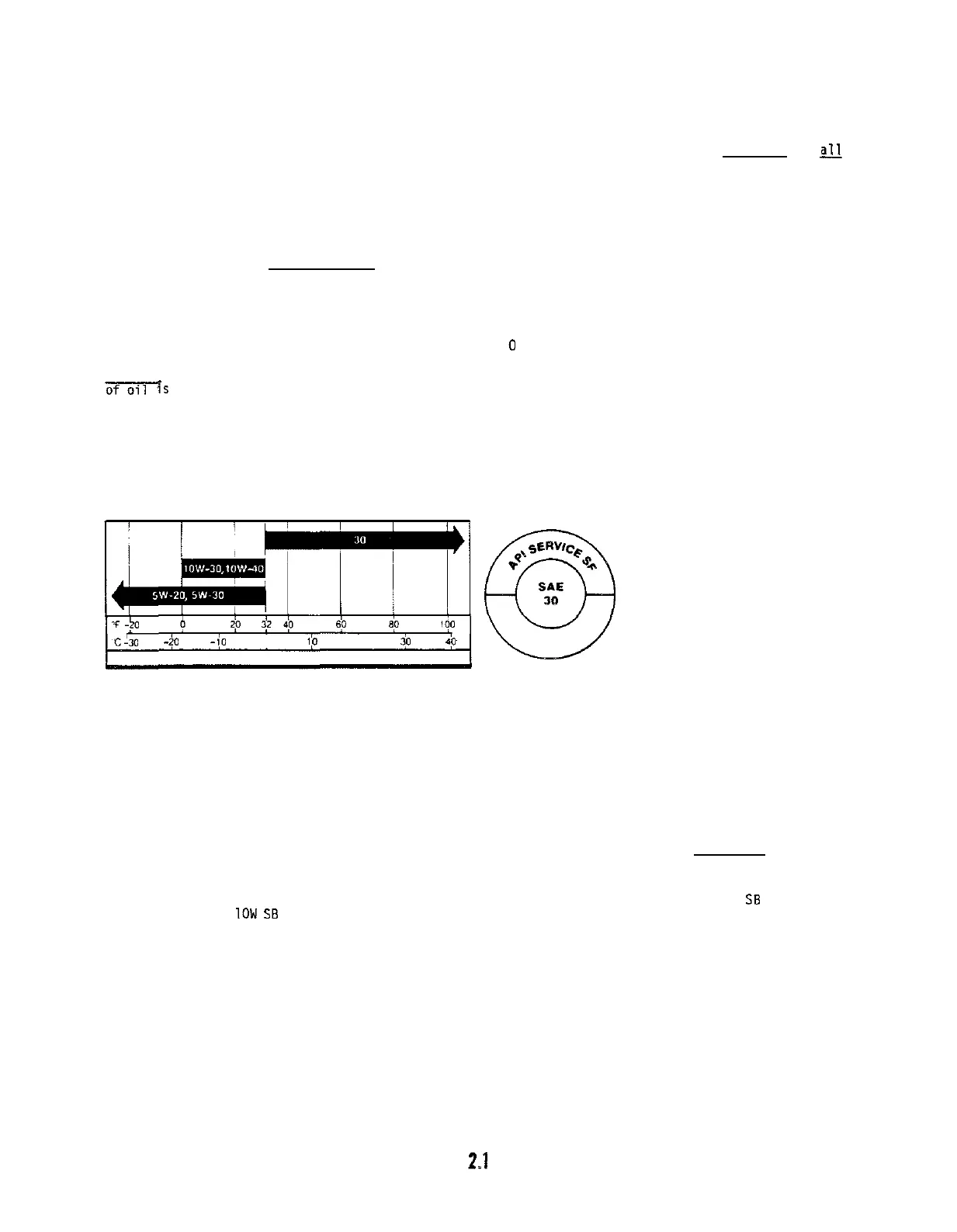

viscosity based on the air temnerature at the time of operation as shown below:

RECOMMENDED SAE VISCOSITY GRADES

0

20

TEMPERATURE RANGE EXPECTED BEFORE NEXT

OIL

CHANGE

A logo or symbol on oil containers identifies the API

service class and SAE viscosity

grade.

The top portion of the symbol

shows service class, such as API

SERVICE SF in the example. The

symbol

may

show additional

categories, such as SE, SF/CC,

CD.

The center portion shows the

viscosity grade, such as SAE 30 in

the example.

Straight 30

-

weight oil is preferred.

If

multiviscosity is used, be aware of the resulting increase in

oil consumption and combustion deposits when used in temperatures above 32°F (O°C).

CAUTION: Using other than Service Class SF oil or extending oil

-

change intervals longer than recommended

could cause engine damage

which is not covered

by

the engine warranty.

RUN

-

IN

OIL

A

special

"

break

-

in

"

oil is used in the factory during the test and run

-

in period. After factory

"

run

-

in

"

, the special oil is drained and the engine is fogged with a special preservative oil.

Further

use of

"

break

-

in

"

oil is

not required nor

recommended for new Kohler Engines.

Engines should be run

-

in

on the detergent type oil listed in the foregoing chart.

Engines should be placed under load from the

very first as this promotes final seating of the rings. Change oil after the initial five hours of

operation.

On overhauled engines or those rebuilt with new short blocks or mini blocks, use 30W

or SC oil

during

sumner and or SC oil during winter for the first five hours of operationto promote

seating

of the piston rings.

If

these oils are unavailable, any 30W oil may be used. After this

initial

run

-

in period, change to the oils listed above.

OIL

CHANGE

On a new or rebuilt engine, change oil after the first 5 hours of operation and then every 50

operating hours thereafter. Change oil more frequently under dirty, dusty conditions.

Drain oil when engine is warm

-

it

flows more freely, carrying away more impurities.

After

draining oil reinstall drain plug. Remove dipstick and add the proper viscosity of oil for the

temperature in which your engine

will

be operating.

Fill to the

"F" mark on the dipstick as opposed

to adding a given quantity of oil. Check level on dipstick before adding more oil.

Oil

capacity is

3.0 quarts.

Add an additional

1/2

quart when oil filter is changed on the K482, K532 and K582 models.

Add an additional 1 quart on K662 models when oil filter element or cartridge is replaced.

Loading...

Loading...