GAS ADAPTERS (COMBINATION GAS

-

GASOLINE)

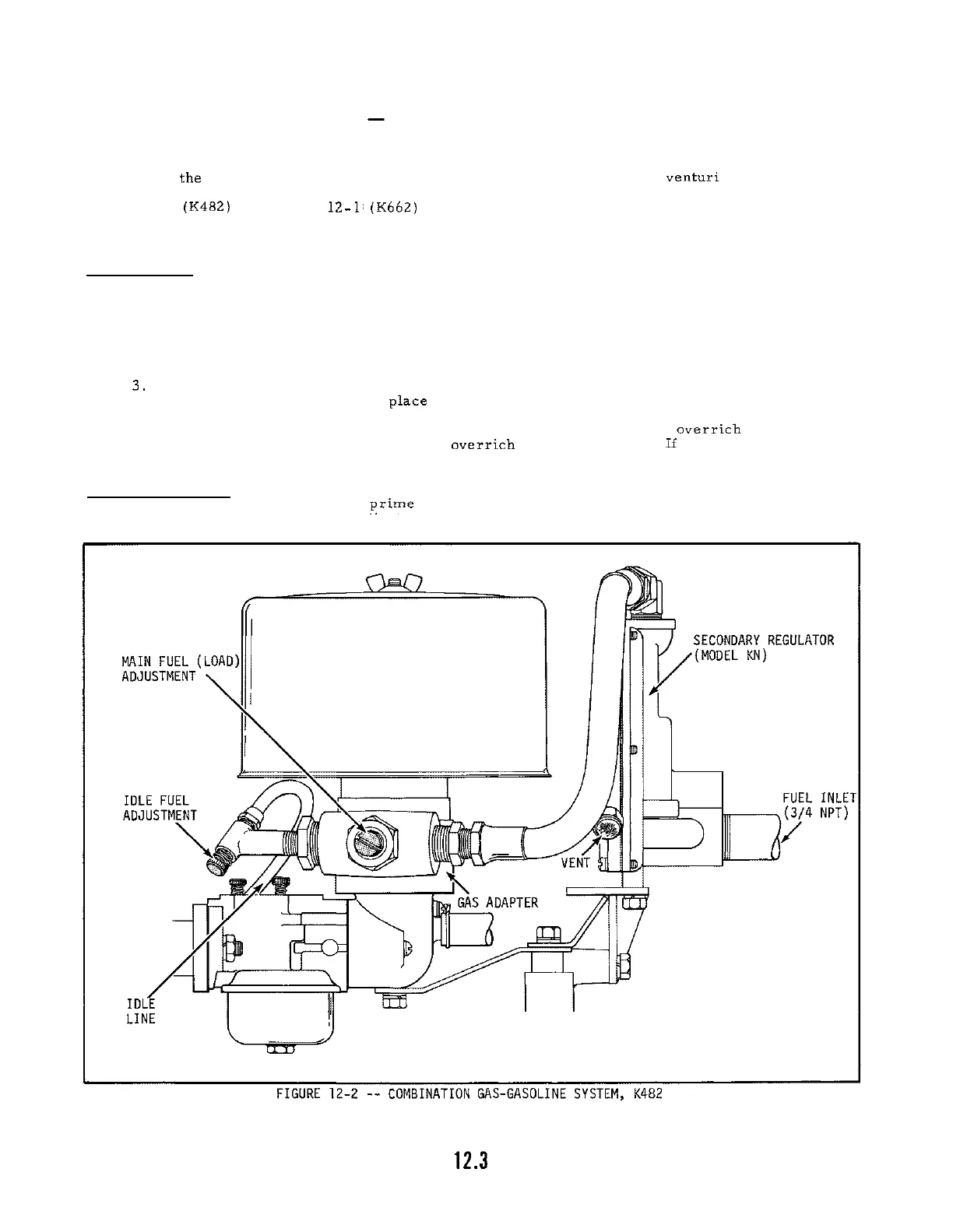

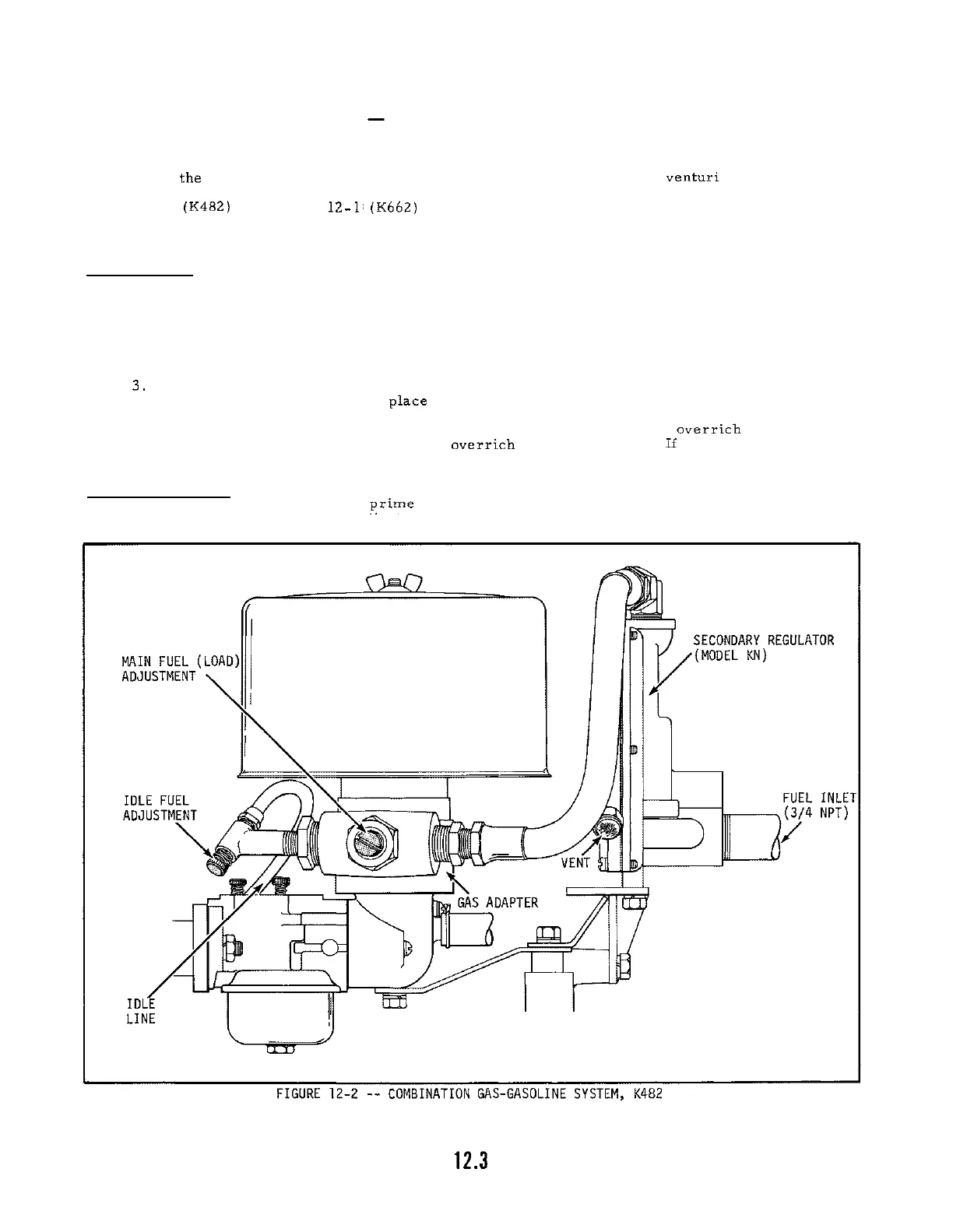

Engines having standard gasoline carburetors are modified to also use gaseous fuels thru the

addition of a gas adapter plus

-

the necessary gas pressure regulatory equipment. The gas adapter is

installed on

the air intake side of the carburetor.

The adapter consists of a

venturi and gas jet

-

arrangement with an external main fuel (load) adjustment and usually an idle fuel adjustment. See

Figure 12

-

2 (K482) and Figure 12-1: (K662) for initial settings. The combination system must also

include fuel shut

-

off valves in both gas and gasoline lines to facilitate switching from one fuel to the

other.

Gas Operation:

Before switching from gasoline to gas, disconnect the automatic choke lead wire on

engines equipped with electric choke. Tape end of lead wire to prevent grounding then proceed as

follows:

1. Close gasoline shut

-

off valve (usually located on fuel filter).

Open gas valve in gas fuel

line.

2.

Depress gas primer (if so equipped) then start engine.

Use Step

3

if final adjustments are

needed.

3.

Allow engine to warm up to normal operating temperatures. Move throttle control to

normal operating speed and

place engine under load.

Loosen locknut then move load adjust

-

ment in until engine. starts to slow down from lean mixture then back out on adjustment past

the point where engine speed picks up then slows down again from

overrich mixture

--

lock

adjustment at point halfway between

overrich and lean settings.

If

engine runs unsteady at

no load,

idle speeds, move idle adjustment screw in or out to attain smoothest idle.

Gasoline Operation: Reconnect electric choke lead (when used) then shut off gas valve and open gaso

-

line valve. If engine is so equipped, qrime gasoline system with priming lever on fuel pump. See

Gasoline Carburetor in Section

4

if adjustment is needed.

Loading...

Loading...