I

I

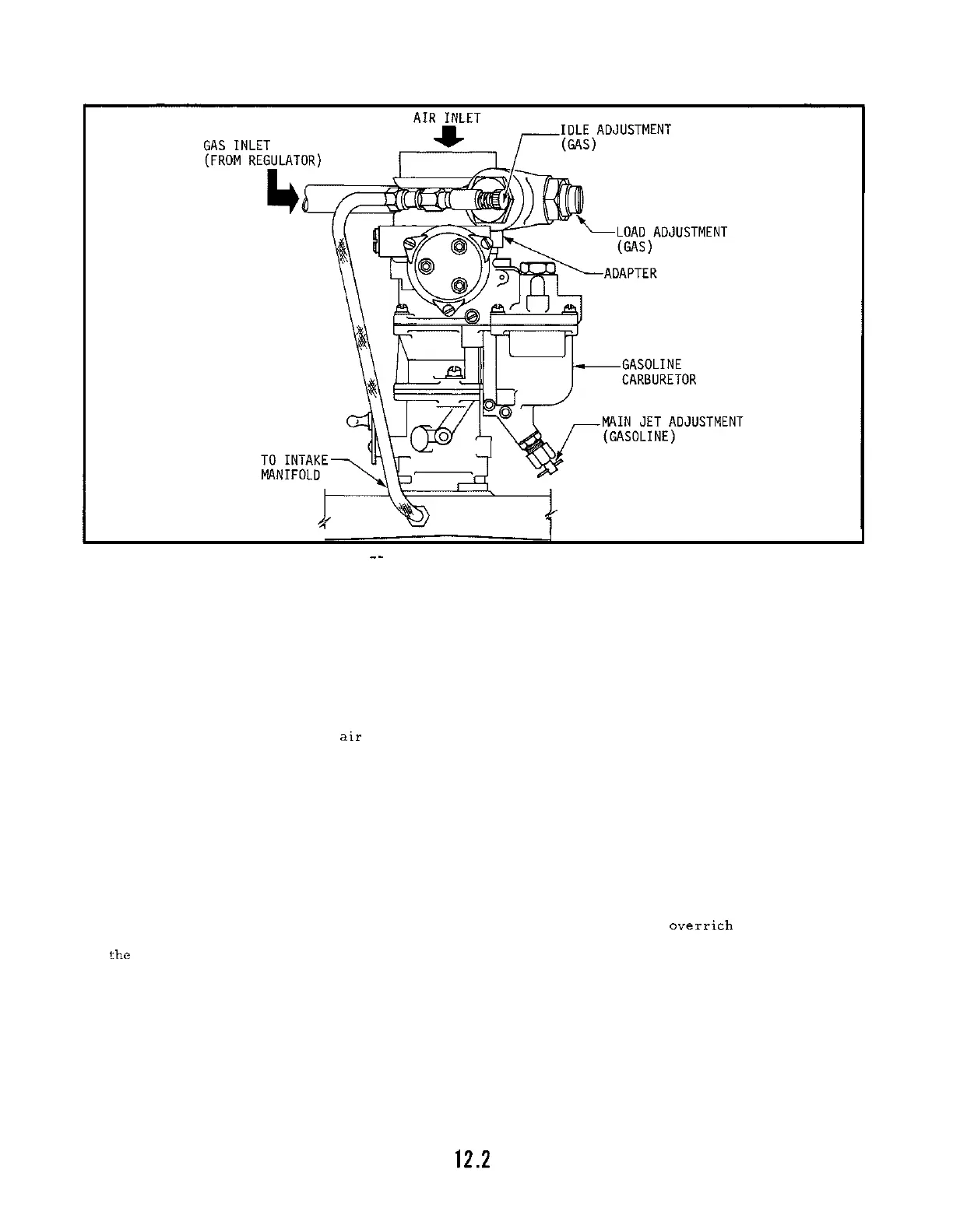

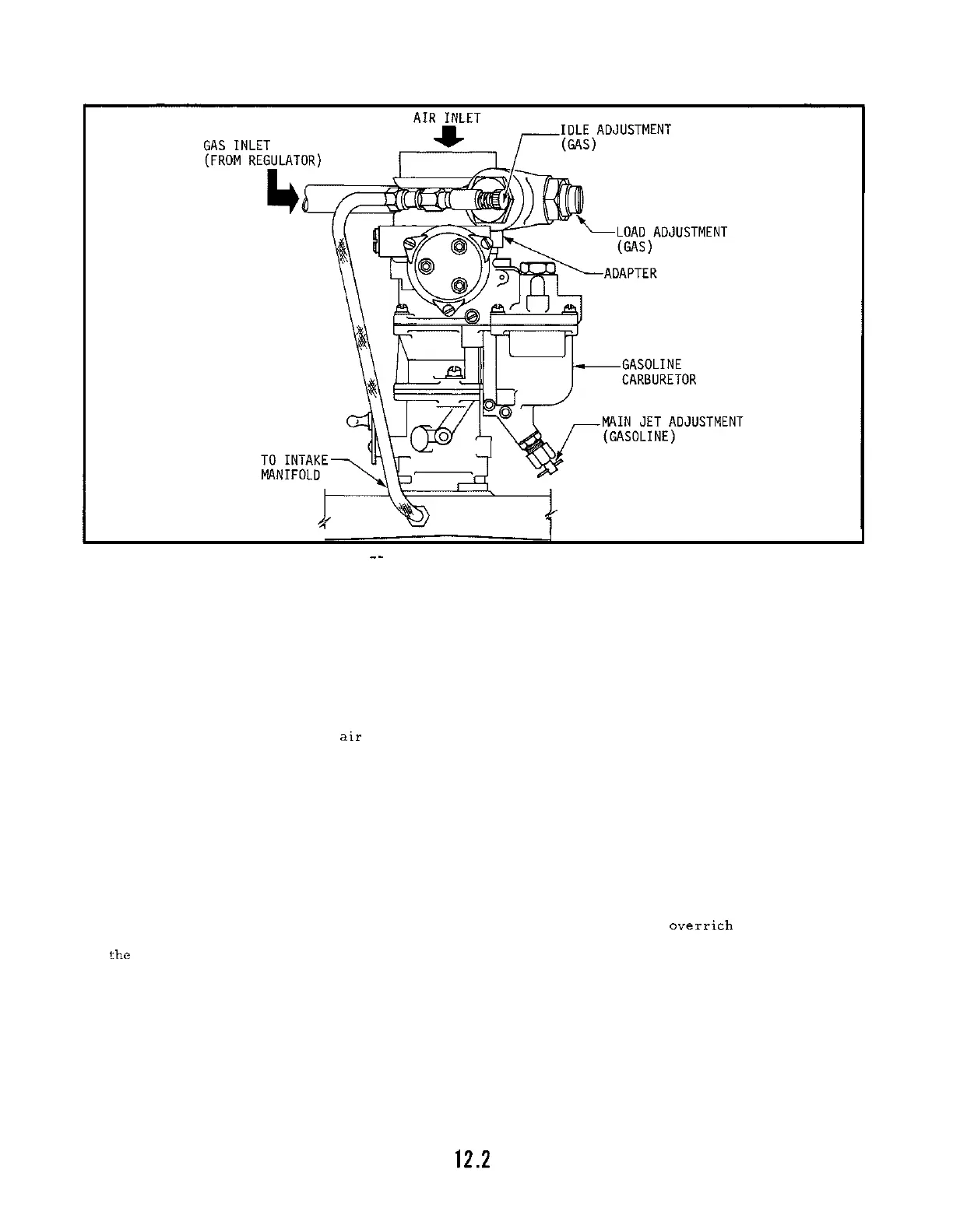

FIGURE

12

-

1

--

COMBINATION GAS

-

GASOLINE SYSTEM,

K662

At idle speed, the velocity of air through a carburetor may not be high enough to draw sufficient

fuel to sustain operation.

For this reason, some carburetors have an idle line which carries a certain

amount of fuel from the secondary regulator to the air intake side of the carburetor where it is intro

-

duced at the lower idle speeds.

When fuel demand drops to a certain point, the regulator diverts fuel

from the main fuel system into the idle fuel system.

On carburetors with this setup, the idle mixture

adjustment is made at the regulator rather than at the carburetor.

The throttle valve within the carburetor regulates the rate of air flow through the carburetor.

When an engine is at top speed, this valve

is

wide open and offers little restriction to air flow. Closing

the throttle causes a decrease in

air flow and lowers engine speed and

power.

As the valve closes.

pressure builds up behind the valve which reduces pressure through the venturi and past the fuel nozzle.

The ratio of air to fuel is thus kept fairly constant at varying speeds.

The diaphragm type uses a diaphragm activated air

-

gas valve to proportion the flow of air and

gas.

A metering valve is linked to the diaphragm, therefore the greater the air flow,

the greater the

valve opening and a corresponding increase in intake of gas. Since the valve was opened only by a

vacuum created by passage of air, it closes completely when the engine

is

stopped.

On engines with the gasoline carburetor, an adapter is installed between the carburetor and air

cleaner. The adapter consists of a gas jet and venturi. Accurate metering of the gas is accomplished

by load and starting

or

idle adjustment screws in the body of the adapter.

On some other systems, a balance line is used to avoid the problem of

overrich fuel mixture

which can be caused by restricted air flow due to a clogged air cleaner. The balance line is connected

to

the atmospheric side of the secondary regulator and to the carburetor air horn. This balance

insures a constant ratio of fuel to air under varying degree of air cleaner restriction.

OPERATING INSTRUCTIONS

-

GAS FUELED ENGINES

Because of the nature of the gaseous fuels, a slightly different procedure should be followed

when starting and making initial adjustment on gas fueled engines. Adjustments vary according to the

type of equipment used.

For example, the idle fuel adjustment is made at the secondary regulator on

some systems while on other types, this

is

done on the carburetor. The different types of carburetors

and regulator equipment are described in the remainder of this section. Adjustment instructions are

stated for each type along with a brief description of the operating principles plus necessary service

and reconditioning information.

Loading...

Loading...