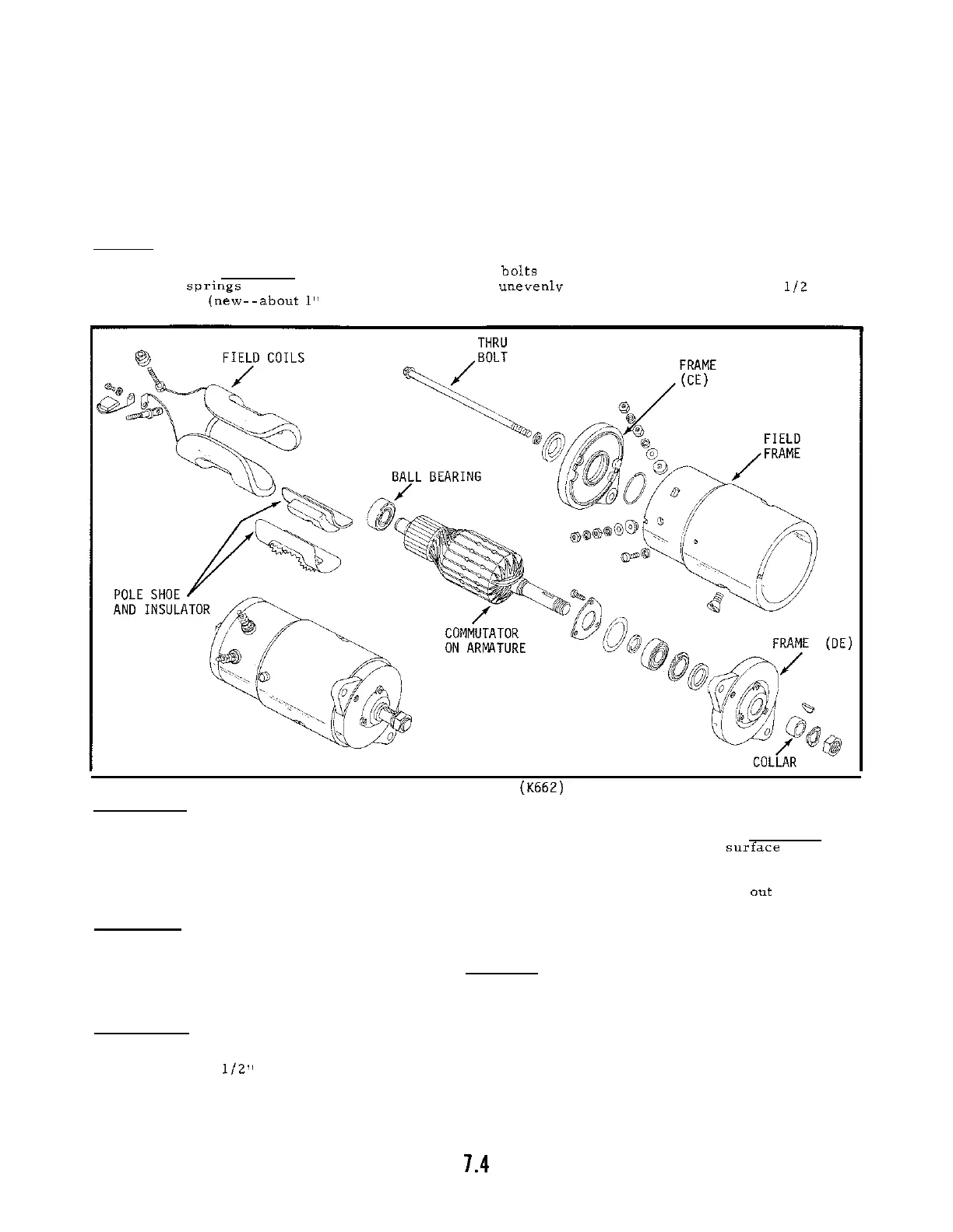

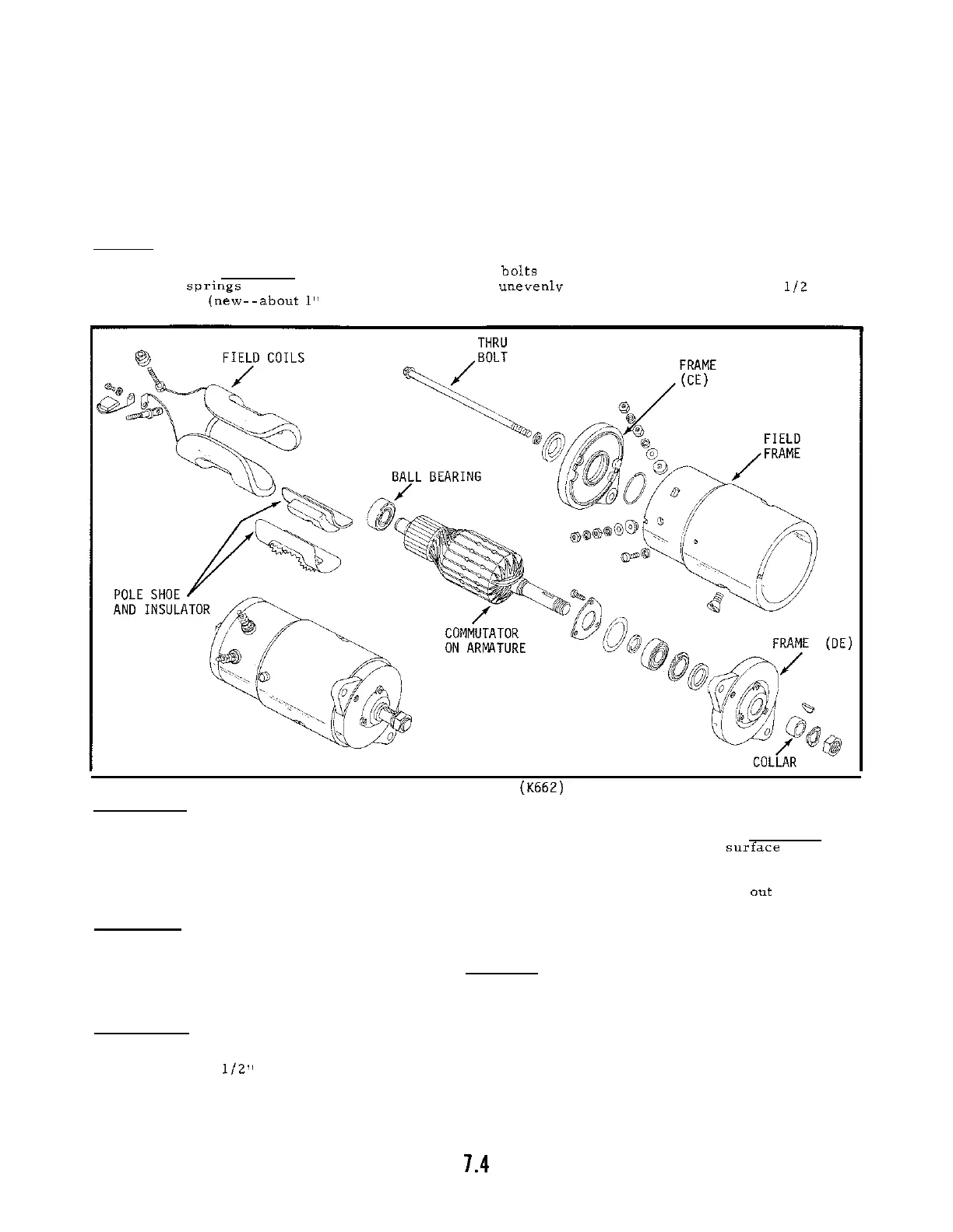

GENERATOR

Most of the generators used on the

K662

are of the

3

brush, shunt wound type DC generators for

12

volt electrical systems.

Some earlier generators have hinged oiler caps and require lubrication at

regular intervals, although most have sealed bearings which do not require regular servicing.

On all

generators, the brushes and commutator must be checked at specific intervals.

Service generators at

the intervals stated in the following service steps.

Brushes

After each 500 hours of operation, remove thru

bolts and take off end frame to observe condition

of brushes,

sprines and holders.

Replace brushes if

unevenly worn or if worn to less than 112 their

original length

(n'w--about 1" long). 'Replace springs if corroded or if blued or discolored from exces

-

sive heat.

Brush arms and brushes must move freely without tendency to bind

or

cock in holders.

L

I

FIGURE

7

-

4

-

-

TYPICAL DC GENERATOR

(K662)

DISASSEMBLED VIEW

Commutator

Observe condition of the commutator at the same time the brushes are serviced (500 hours).

If

dirty, clean with No. 00 Sandpaper.

Make sure dust is removed after cleaning.

If suriace is grooved,

rough or out of round, remove armature and place in lathe so that commutator can be turned down.

Remove only enough material to make commutator smooth and round. After resurfacing, undercut the

mica insulation 1/32

"

deep.

Finish with No. 00 Sandpaper after undercutting and blow

out all dust.

Lubrication

On generator having the hinged cap oilers, add several drops of SAE 20 weight oil to both caps

(at commutator and drive end frames) after each 200 hours of operation or every fourth oil change

period.

CAUTION:

Do not add too much oil as this may cause overheating of the bearing.

Add only a

few drops at each service period.

Belt Tension

Occasionally check condition

of

belt and also check belt tension.

Belt should be adjusted so that

it deflects about

1/2" when depressed with finger at midpoint on upper span. Too little tension results

in belt slippage and rapid wear of the belt. Excessive tension also causes rapid wear and can damage

generator bearings. Loosen generator mounting bracket and move generator until proper tension is

attained.

Loading...

Loading...