4.

Install gasket and governor then secure to gear cover with two capscrews.

Before closin

g

gear cover sight hole with plug, check to make sure beveled tooth on cam can he observed

in hole.

5.

Ignition timing must be readjusted after governor is installed.

On the K482 and

K532, this

is

done by loosening the capscrews and rotating governor

--

see Ignition Timing instructions

(Section 6) for exact details.

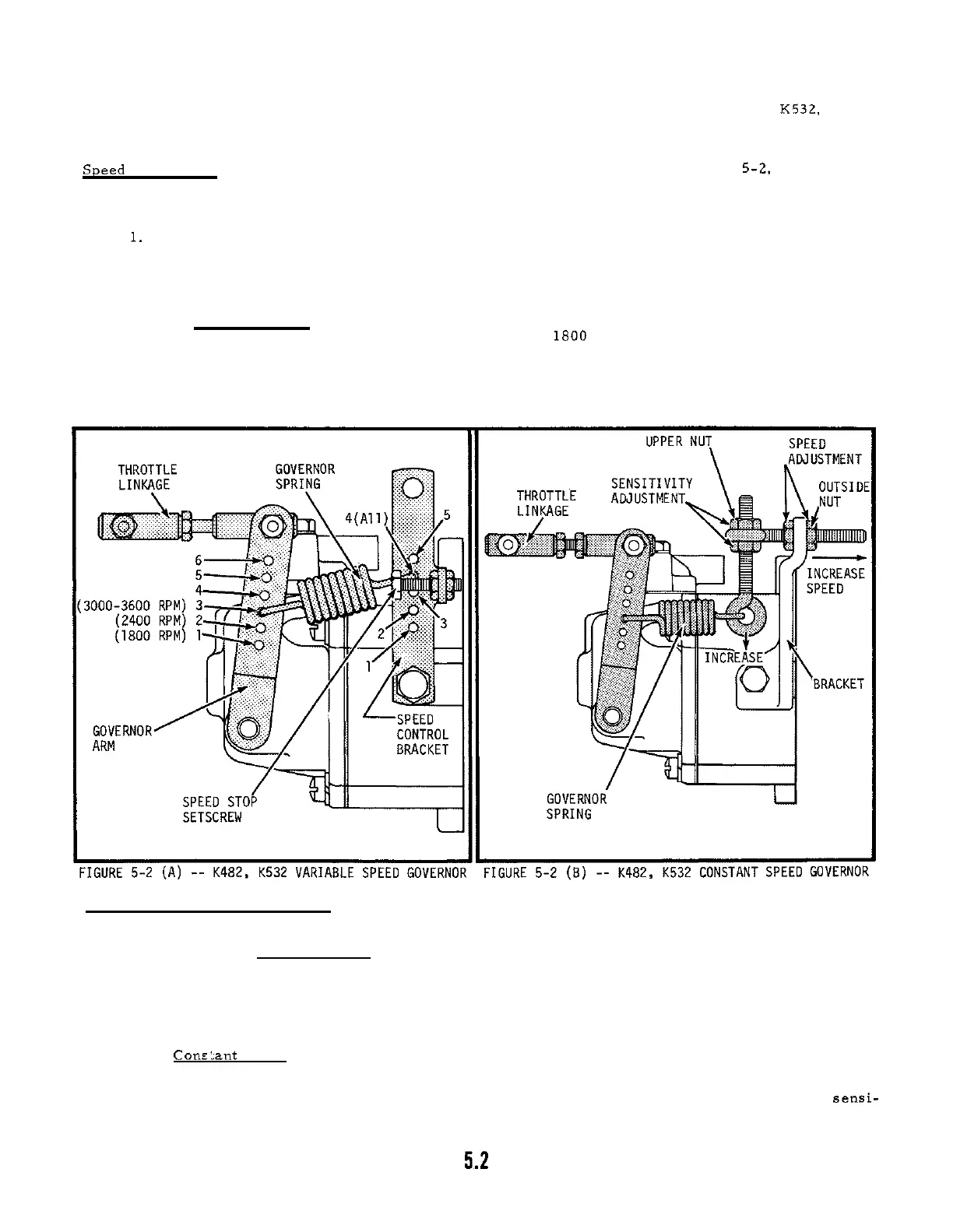

Speed Adjustment:

On most engines with the variable speed type governor (See Figure

5-2, View

A),

maximum speed is set at 3600 RPM no load.

On

some applications, a lower maximum speed is specified

-

-

make sure that the allowable speed for the particular application is not exceeded. Use the following

procedure to readjust speed Limit on engines with the variable speed governor:

1. Start engine and operate at full throttle (no load).

2. Check engine speed with hand tachometer

-

-

if within

50

RPM of specified limit, readjust

-

ment

is

not absolutely necessary.

3.

Loosen locking nuts on speed stop setscrew

-

-

turn screw out or in as necessary to attain

specified top speed. Retighten locking nuts to secure stop at new setting.

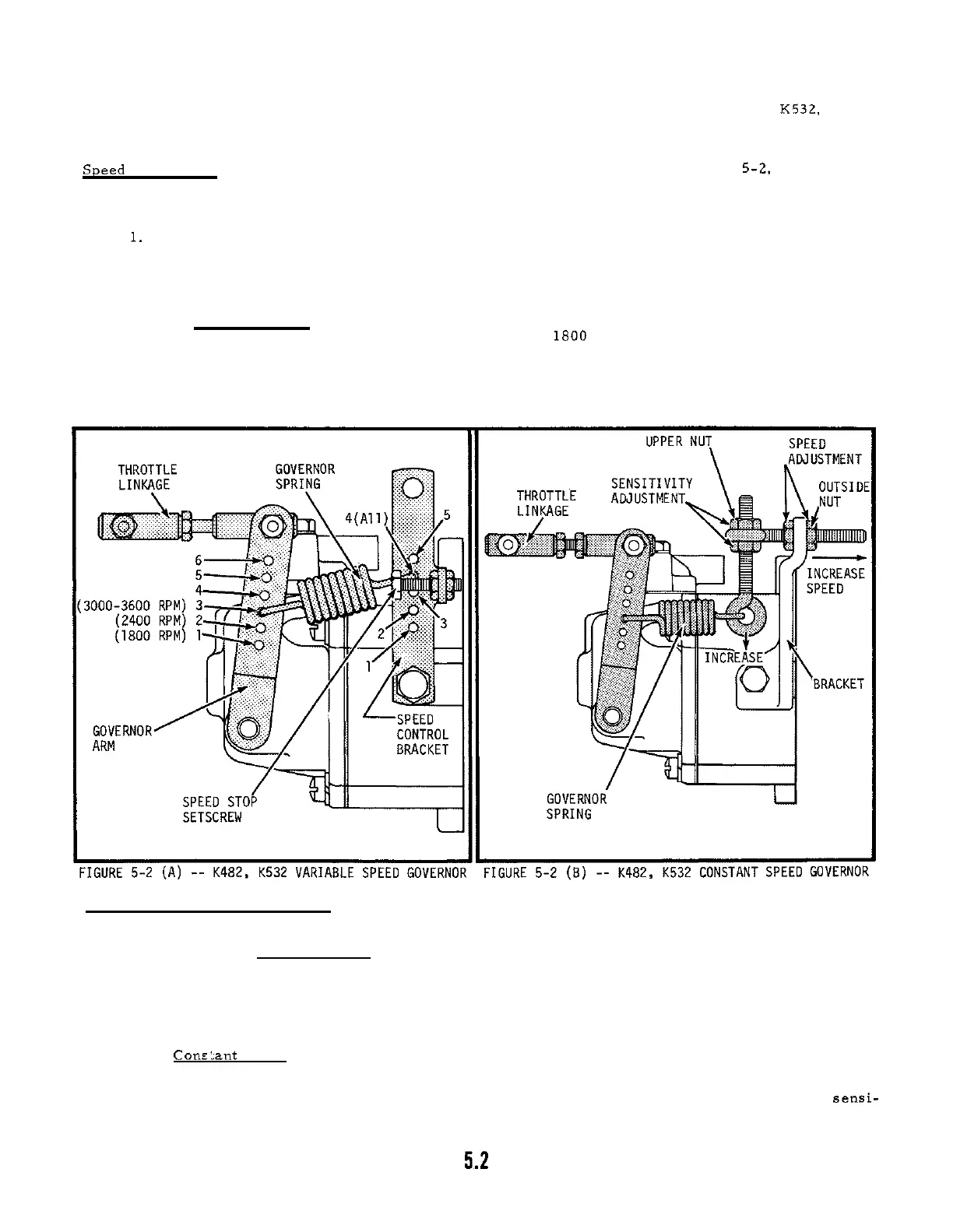

With the Constant Speed type governor (Figure 5

-

2

-

-

View

B),

the throttle shaft is fixed at a

definite length to establish a specific operating speed such as

1800 RPM for 60 cycle electric plants.

Any variation in speed causes frequency changes in output of the generator

--

for this reason, only slight

readjustment of speed

is

possible with constant speed governors.

To increase speed, loosen the inside

speed adjusting locking nut and tighten the outside nut to draw the eye of the holt closer to the bracket

-

-

to aecrease speed, loosen the outside nut and tighten the inside nut.

After speed is correct, tighten

the nut that was loosened to lock the eye bolt at the new setting.

Governor Sensitivity Adjustment:

If the governor is too sensitive, speed surging will occur with change

in load.

If a big drop in speed occurs when normal load is a

pp

lied, the governor should be set for

greater sensitivity.

On engines with Variable Speed governors, sensitivity can be adjusted by repositioning the gover

-

nor spring in different holes in the governor arm.

Normal hole settings for different operating speeds

are shown in View A of Figure 5

-

2.

To make governor control more sensitive, move spring hook into

holes higher up on the governor arm.

To make governor control less sensitive, move spring hook in

holes spaced further apart. Move spring one hole at a time and recheck sensitivity and speed after

each move.

With

Conrlant Speed governors, sensitivity is changed by repositioning the sensitivity adjusting

eye holt as shown in Figure 5

-

2

--

View

B.

To make governor control more sensitive, loosen the upper

nut and tighten the lower nut to force the eye bolt downward.

To make control less sensitive, draw the

eye holt upward by loosening the lower nut and tighten the upper nut.

Recheck speed after making

sensi-

tivity adjustment. Retighten nut that was loosened to lock eye bolt at the new setting.

Loading...

Loading...