43

Disassembly/Inspection and Service

14 690 01 Rev. G KohlerEngines.com

Some important points to remember when servicing

piston rings:

1. Cylinder bore must be de-glazed before service ring

sets are used.

2. If cylinder bore does not need re-boring and if old

piston is within wear limits and free of score or scuff

marks, old piston may be reused.

3. Remove old rings and clean up grooves. Never

reuse old rings.

4. Before installing new rings on piston, place top 2

rings, each in turn, in its running area in cylinder

bore and check end gap. Compare ring gap to

Clearance Specications.

5. After installing new compression (top and middle)

rings on piston, check piston-to-ring side clearance.

Compare clearance to Clearance Specications. If

side clearance is greater than specied, a new

piston must be used.

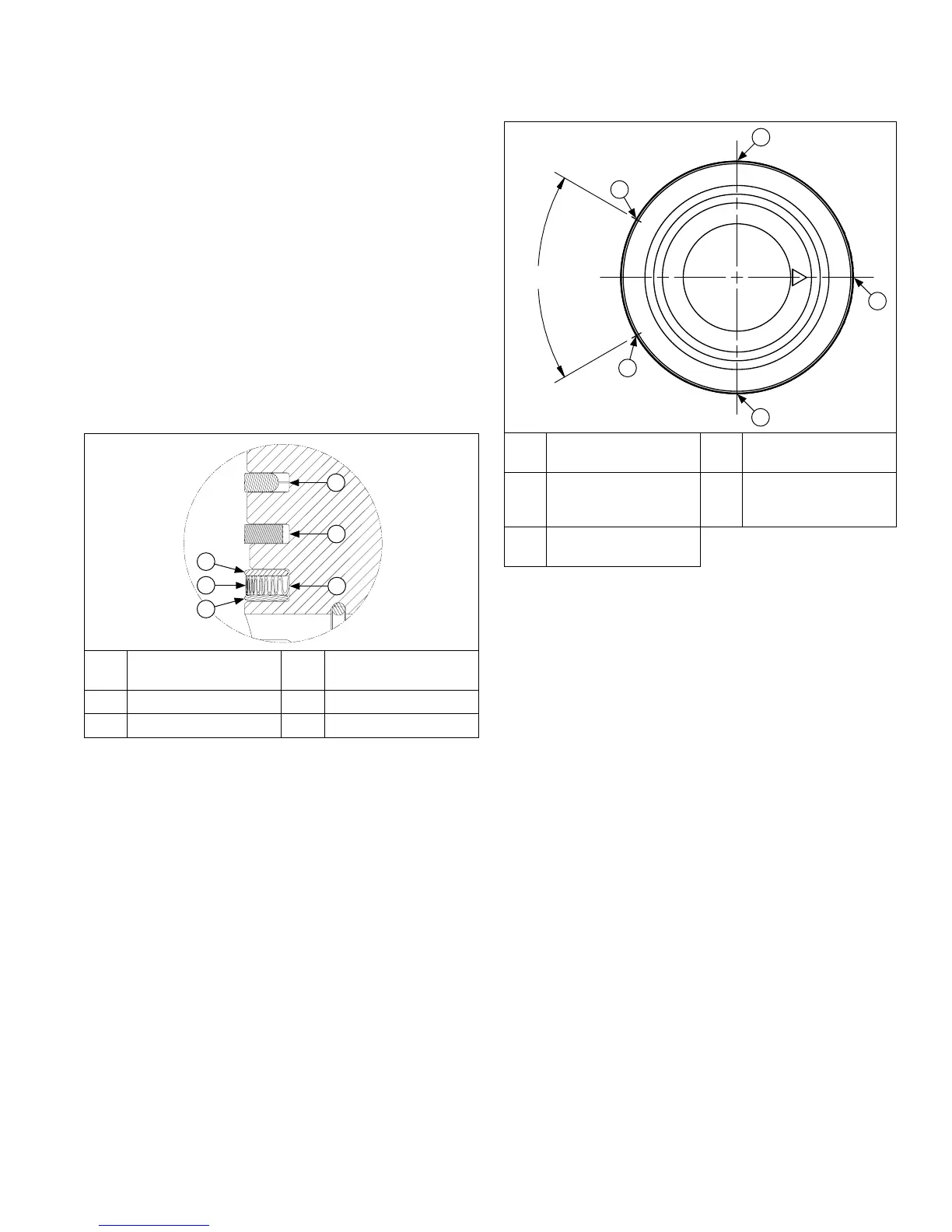

Install New Piston Rings

C

D

E

F

B

A

A

Top Compression

Ring

B

Middle Compression

Ring

C Oil Control Ring D Top Rail

E Expander Ring F Bottom Rail

Piston Ring Orientation

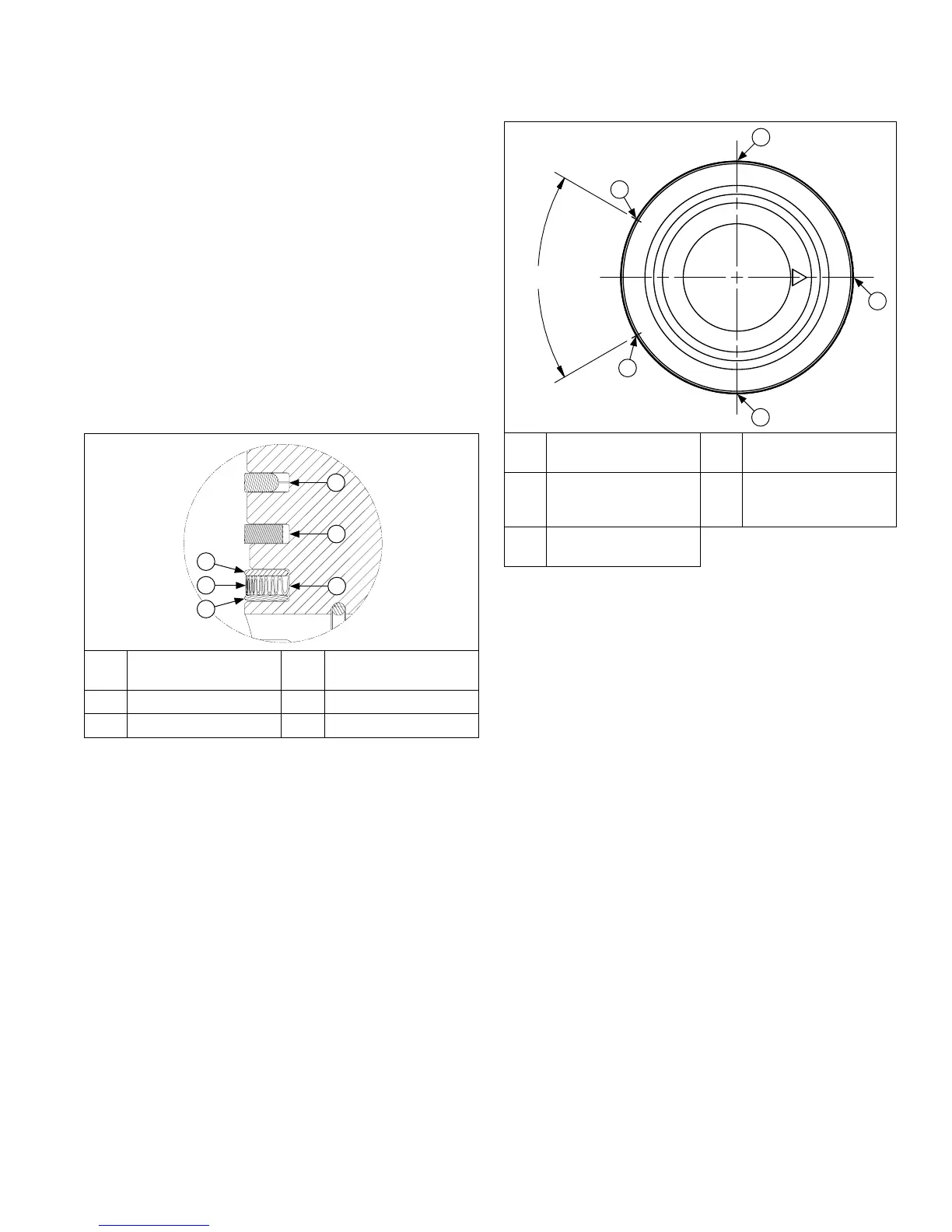

A

B

C

D

E

(≥ 60°)

A

Oil Ring Expander

Gap

B Bottom Oil Rail Gap

C Top Oil Rail Gap D

Intermediate

Compression

Ring Gap

E

Top Compression

Ring Gap

NOTE: Rings must be installed correctly. Install oil

control ring assembly (bottom groove) rst,

middle compression ring (center groove)

second, and top compression ring (top groove)

last. Oil control ring assembly is a three-piece

design, and consists of a top rail, expander ring,

and bottom rail.

Use a piston ring expander to install rings.

1. Oil control ring assembly (bottom groove): Install

expander rst then bottom rail and top rail last. Make

sure ends of expander are not overlapped. Adjust

ring gaps.

2. Middle compression ring (center groove): Install

middle compression ring using a piston ring

expander tool. Make sure identication mark is up or

colored dye stripe (if contained) is left of end gap.

Adjust ring gaps.

3. Top compression ring (top groove): Install top

compression ring using a piston ring expander tool.

Make sure identication mark is up or colored dye

stripe (if contained) is left of end gap. Adjust ring

gaps.

Loading...

Loading...