51

Reassembly

14 690 01 Rev. G KohlerEngines.com

Install Flywheel

CAUTION

Damaging Crankshaft and Flywheel can

cause personal injury.

Using improper procedures can lead to broken

fragments. Broken fragments could be thrown from

engine. Always observe and use precautions and

procedures when installing ywheel.

NOTE: Before installing ywheel make sure crankshaft

taper and ywheel hub are clean, dry, and

completely free of lubricants. Presence of

lubricants can cause ywheel to be over

stressed and damaged when mounting nut is

torqued to specication.

NOTE: Make sure ywheel key is installed properly in

keyway. Flywheel can become cracked or

damaged if key is not properly installed.

NOTE: Always use a ywheel strap wrench to hold

ywheel when tightening ywheel fastener. Do

not use any type of bar or wedge to prevent

ywheel from rotating, as these parts could

become cracked or damaged.

1. Install key, into crankshaft keyway. Make sure key is

fully seated.

2. Install ywheel onto crankshaft aligning keyway with

key.

3. Align teardrop slot on fan with raised teardrop on

ywheel. Align drive cup on ywheel, and install and

hand tighten nut.

4. Using a ywheel strap wrench, hold ywheel still

while simultaneously tightening nut to 51.5 N·m

(38 ft. lb.).

Install Electric Starter (if equipped)

Align and mount electric starter onto crankcase. Install

and torque screws to 9.5 N·m (84 in. lb.).

Install Ignition Module

NOTE: If stud for mounting ignition module was not kept

segregated from 2 studs for mounting fuel tank,

compare their lengths and choose short one.

1. Rotate ywheel so ignition magnets are away from

ignition module legs. Position ignition module on

legs with kill tab down.

2. Loosely thread stud and screw into appropriate leg.

Pull module away from ywheel and tighten stud to

hold it in place. Rotate ywheel so ignition magnet is

aligned with module.

3. Set air gap by placing a 0.254 mm (0.010 in.) plastic

feeler gauge between magnet and module. Loosen

stud and let magnet draw module against feeler

gauge. Torque fasteners to 10 N·m (88 in. lb.).

4. Rotate ywheel to release feeler gauge, and check

module does not come in contact with magnet.

Recheck air gap.

5. Connect kill lead to ignition module kill tab.

Install Fuel Tank

1. Secure fuel tank bracket to crankcase by torquing

nut or screw to 8 N·m (71 in. lb.).

2. Secure top of fuel tank to crankcase by installing

threaded studs. Torque studs to 10 N·m (88 in. lb.).

3. Install spacers on studs.

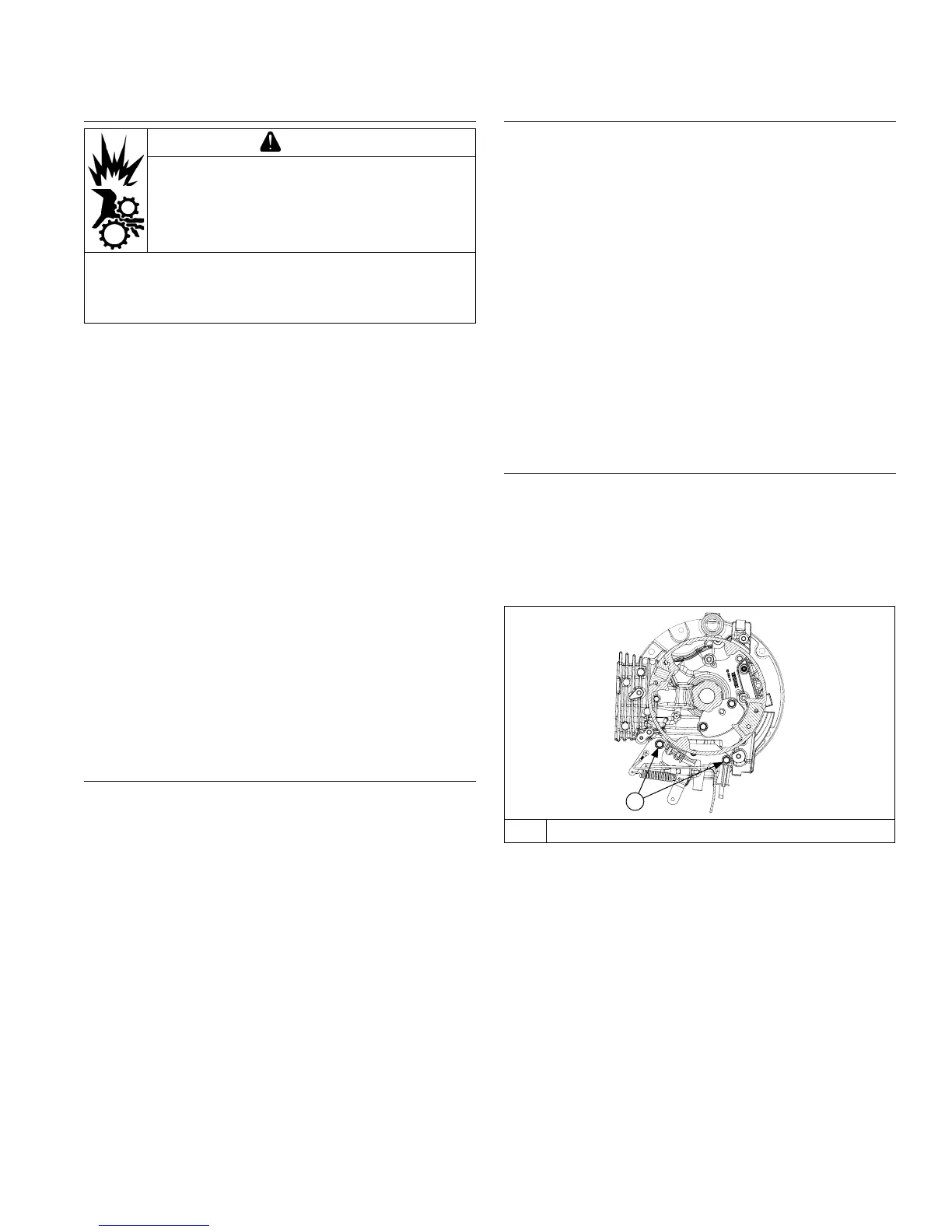

Install Flywheel Brake Spring

A

A Brake Assembly Screws

Using a pliers, attach ywheel brake spring onto bracket

hook.

Loading...

Loading...