.

MAINTENANCE

SERVICE PROCEDURE

EVERY 250 HOURS SERVICE

CHECK OIL LEVEL IN DIFFERENTIAL CASE, ADD OIL

WARNING

The parts and oil are at high temperature after the engine is stopped, and may cause serious burns. Wait for the temperature

to go down before starting the operation.

If there is still pressure remaining inside the case, the oil or plug may fly out. Turn the plug slowly to release the pressure, then

remove it carefully.

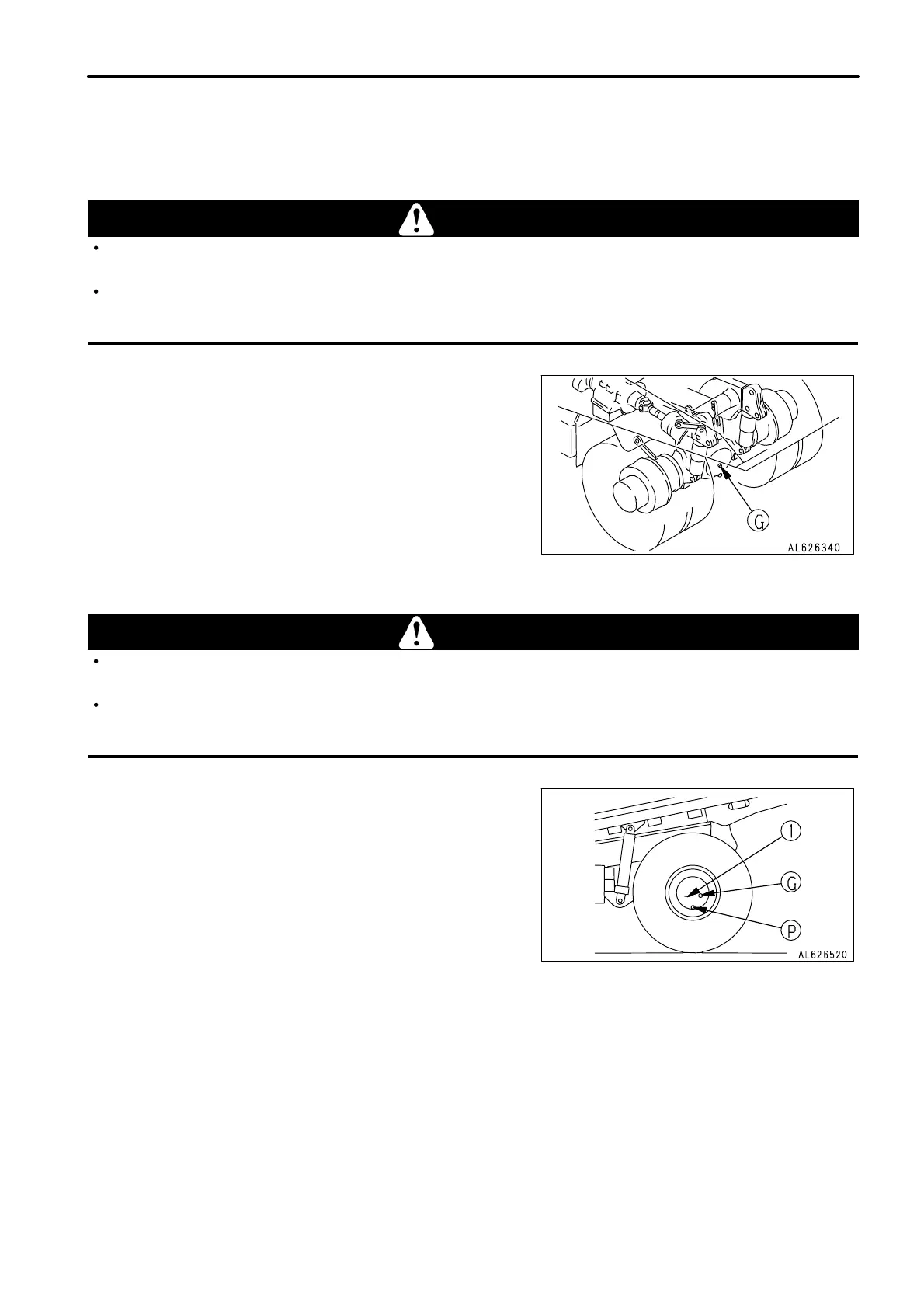

1.

Remove plug (G) and check that the oil level is near the bottom

of the plug hole.

2.

If the oil level is too low, add oil through the plug hole until the

oil overflows.

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL

WARNING

The parts and oil are at high temperature after the engine is stopped, and may cause serious burns. Wait for the temperature

to go down before starting the operation.

If there is still pressure remaining inside the case, the oil or plug may fly out. Turn the plug slowly to release the pressure, then

remove it carefully.

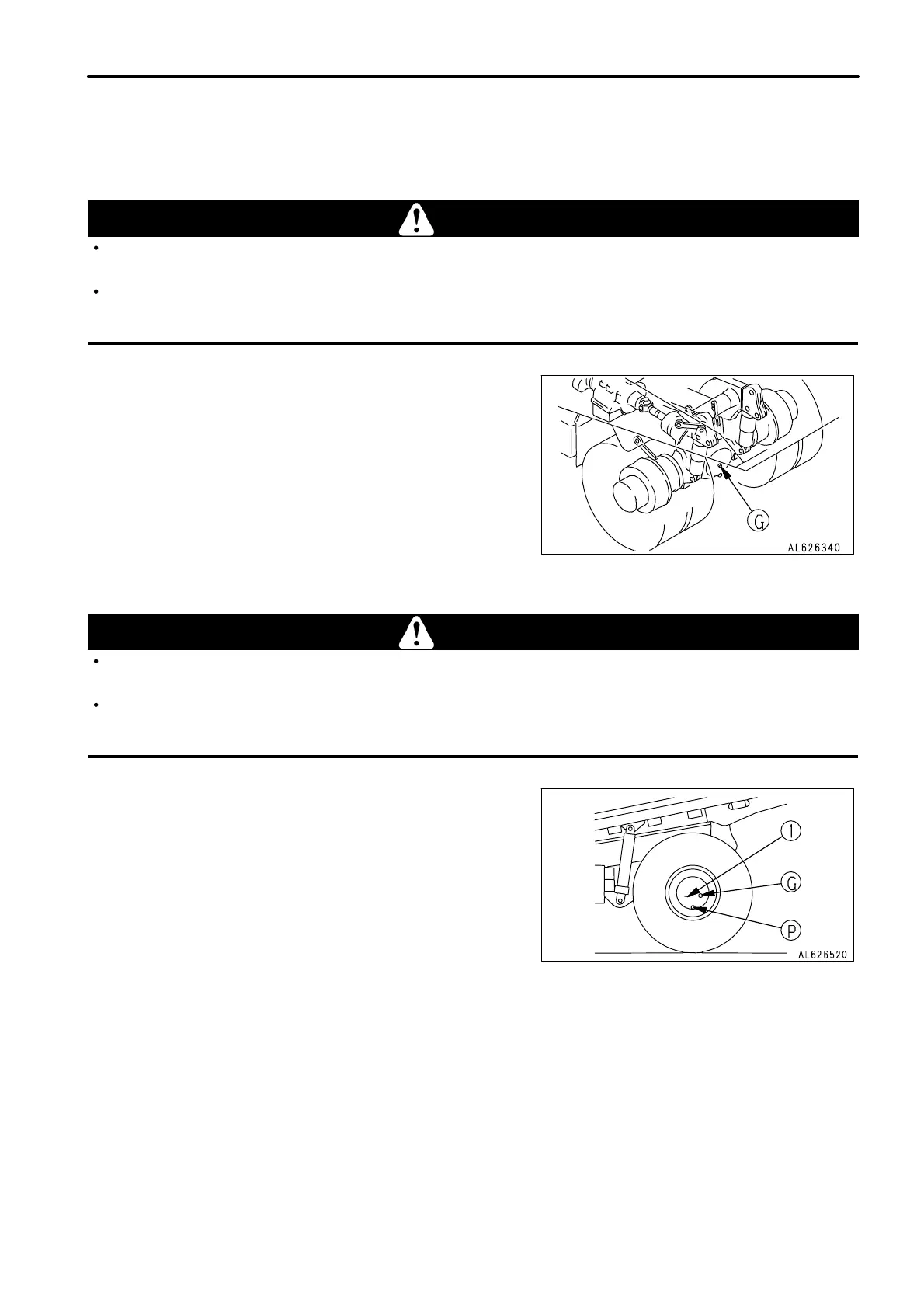

1. Stop the machine so that casting line (1) is horizontal and drain

plug (P) is immediately at the bottom.

2.

Remove plug (G) and check that the oil level is near the bottom

of the plug hole.

3.

If the oil level is too low, add oil through the plug hole until the

oil overflows.

4 - 49

Loading...

Loading...