.

MAINTENANCE

SERVICE PROCEDURE

BLEED AIR FROM REAR BRAKE

WARNING

Stop the machine on level ground and put blocks under the wheels before bleeding the air.

To make it easier to bleed the air, warm the oil up to a temperature of at least 40°C (104°F) before bleeding the air.

Bleed the air from the rear brakes in the same way on both the left and right sides.

1. Start the engine, check that the oil in the transmission case is the specified level, and check if the brake oil

pressure caution lamp is out.

2.

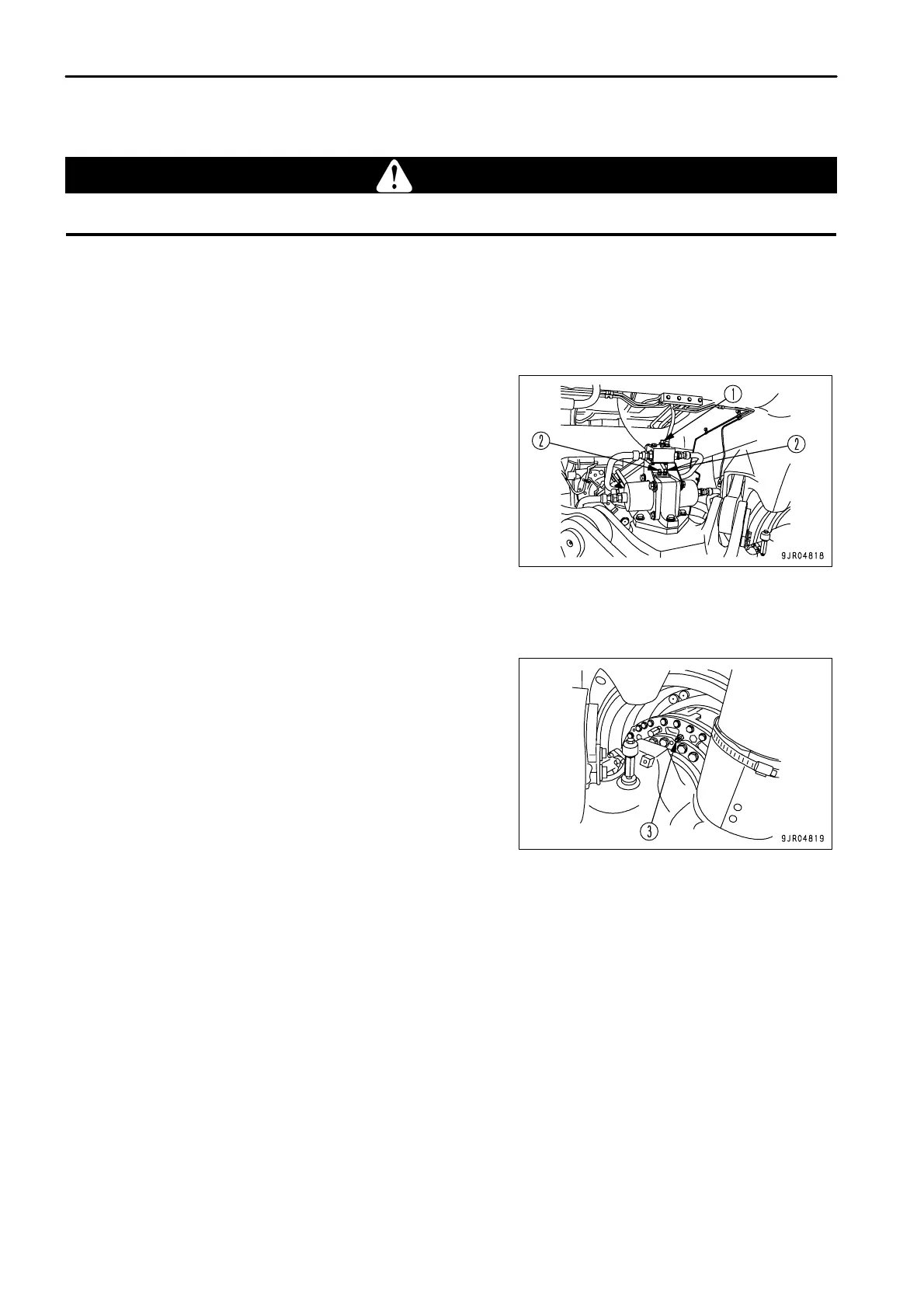

Remove the cap installed to bleeder screw (1) in the block,

then insert a vinyl hose.

Prepare a container with oil in it and put the other end of the

hose approx. 50 mm (2.0 in) into the oil.

(Use a commercially available vinyl hose.)

3.

Depress the brake pedal and loosen bleeder screw (1) approx.

3/4 turns. Keep the pedal depressed until no more bubbles

come out from the vinyl hose.

4.

Pull the retarder control lever and loosen bleeder screw (1)

approx. 3/4 turns. Keep the retarder control lever depressed

until no more bubbles come out from the vinyl hose.

5.

After bleeding the air, tighten bleeder screw (1) securely and fit the cap.

6.

Repeat the above procedure in Step 4 to bleed the air from bleeder screw (2) of the slack adjuster.

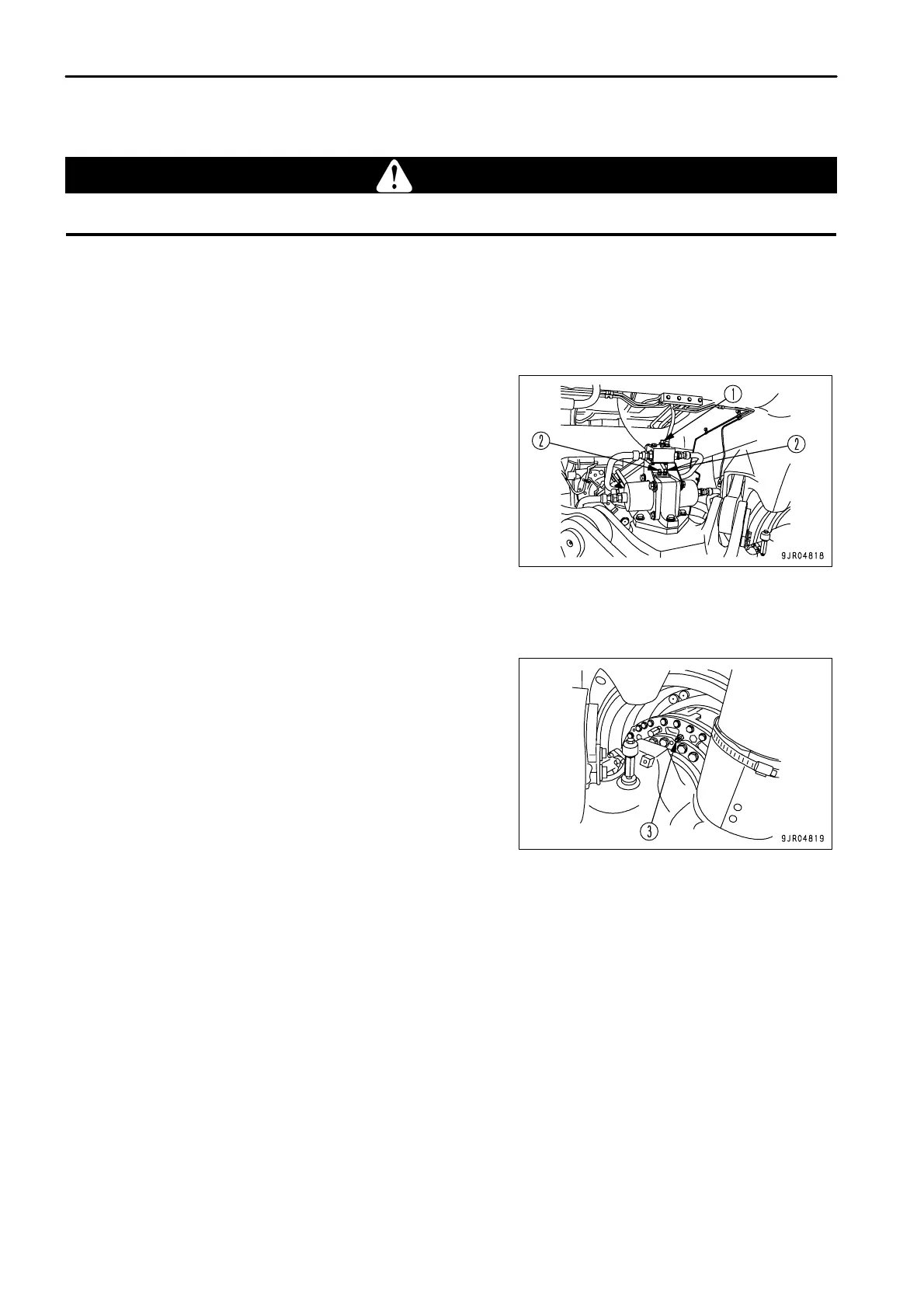

7. Repeat the above procedure in Step 4 to bleed the air from

bleeder screw (3) of the rear brake.

8.

Add oil. For details, see "CHECK OIL LEVEL IN

TRANSMISSION CASE, ADD OIL (PAGE 3-76)".

4 - 40

Loading...

Loading...