.

MAINTENANCE

SERVICE PROCEDURE

EVERY 100 HOURS SERVICE

CHECK ALCOHOL LEVEL IN ALCOHOL INJECTOR, ADD ALCOHOL

(Machines equipped with alcohol injector)

During the cold season, check the ethyl alcohol level every 100

hours on the service meter.

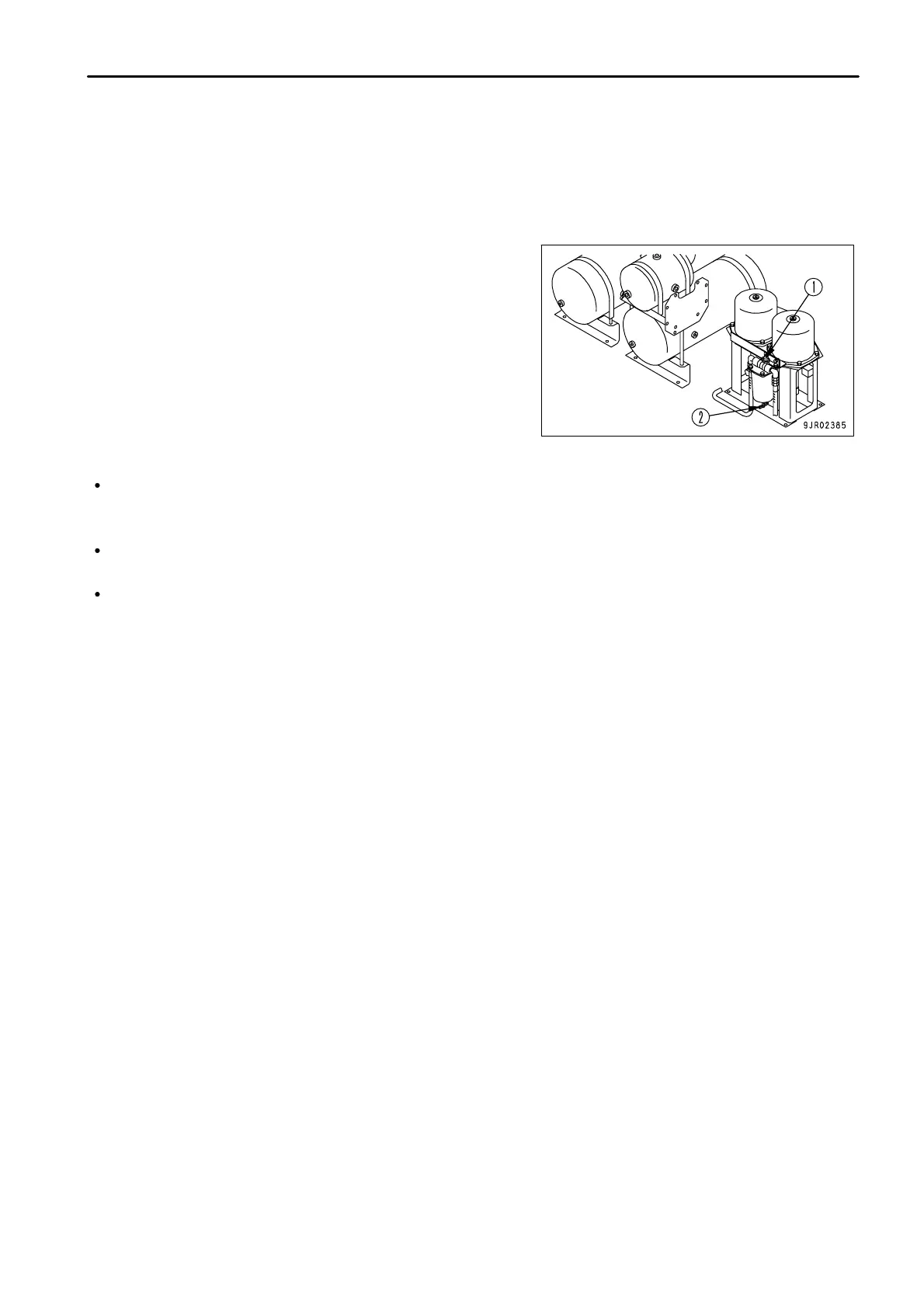

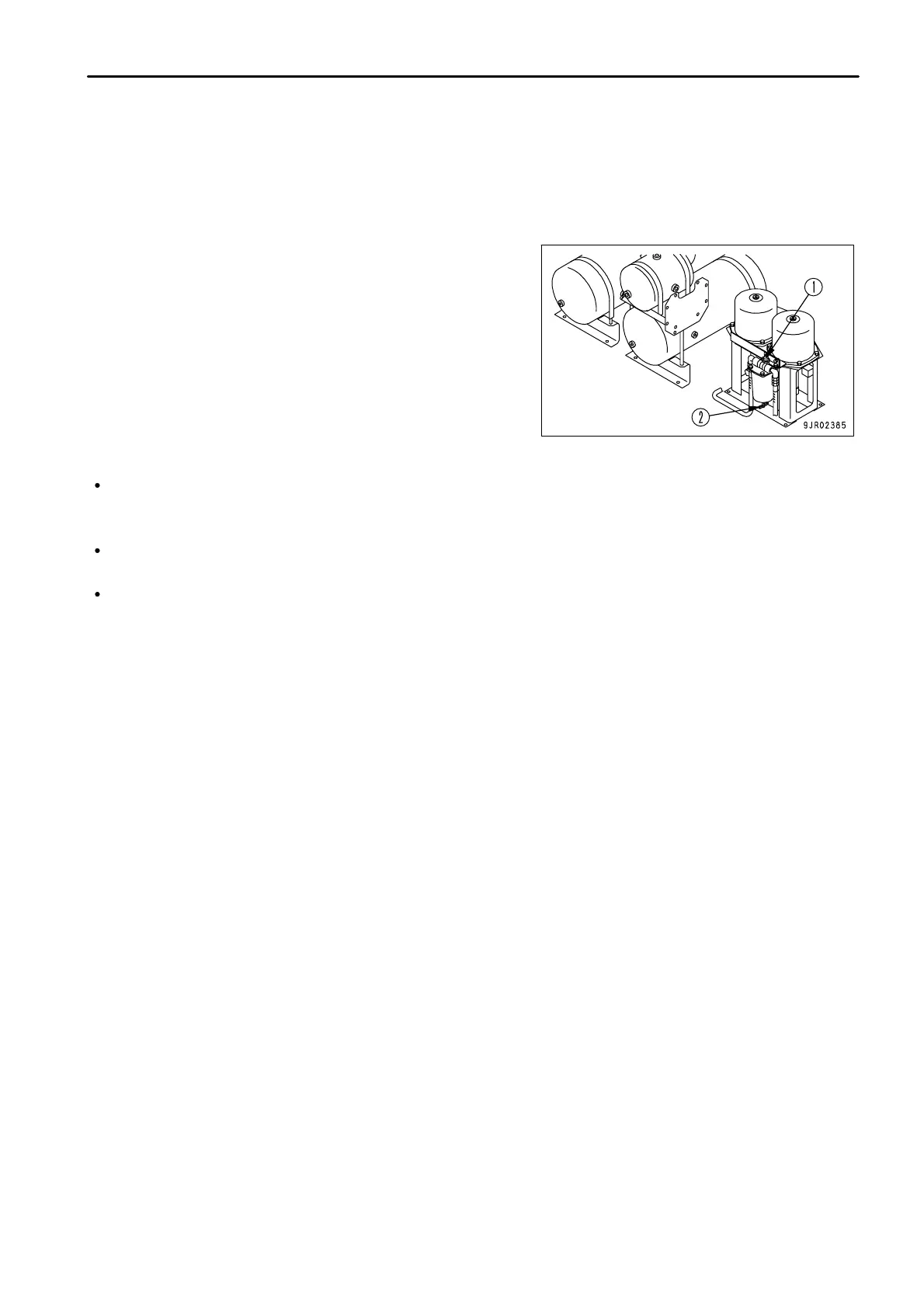

When removing filler cap (1) of the alcohol injector to carry out the

inspection, loosen it slowly to release the remaining pressure

before removing it.

If the alcohol level is low, add alcohol to the bottom surface of the

threaded portion of the filler cap.

REMARK

On this machine, air is used to operate the brakes. When the machine is operated in cold weather, the moisture

in the air will freeze and cause problems such as defective operation of the valve, so add ethyl alcohol to the air

system to lower the freezing point.

When filling the alcohol injector with alcohol before the cold season, release the remaining pressure, remove the

cap, then add 1.4 liters (0.37 US gal) of ethyl alcohol through the filler port.

After the cold season, loosen drain valve (2) and drain the ethyl alcohol.

4 - 37

Loading...

Loading...