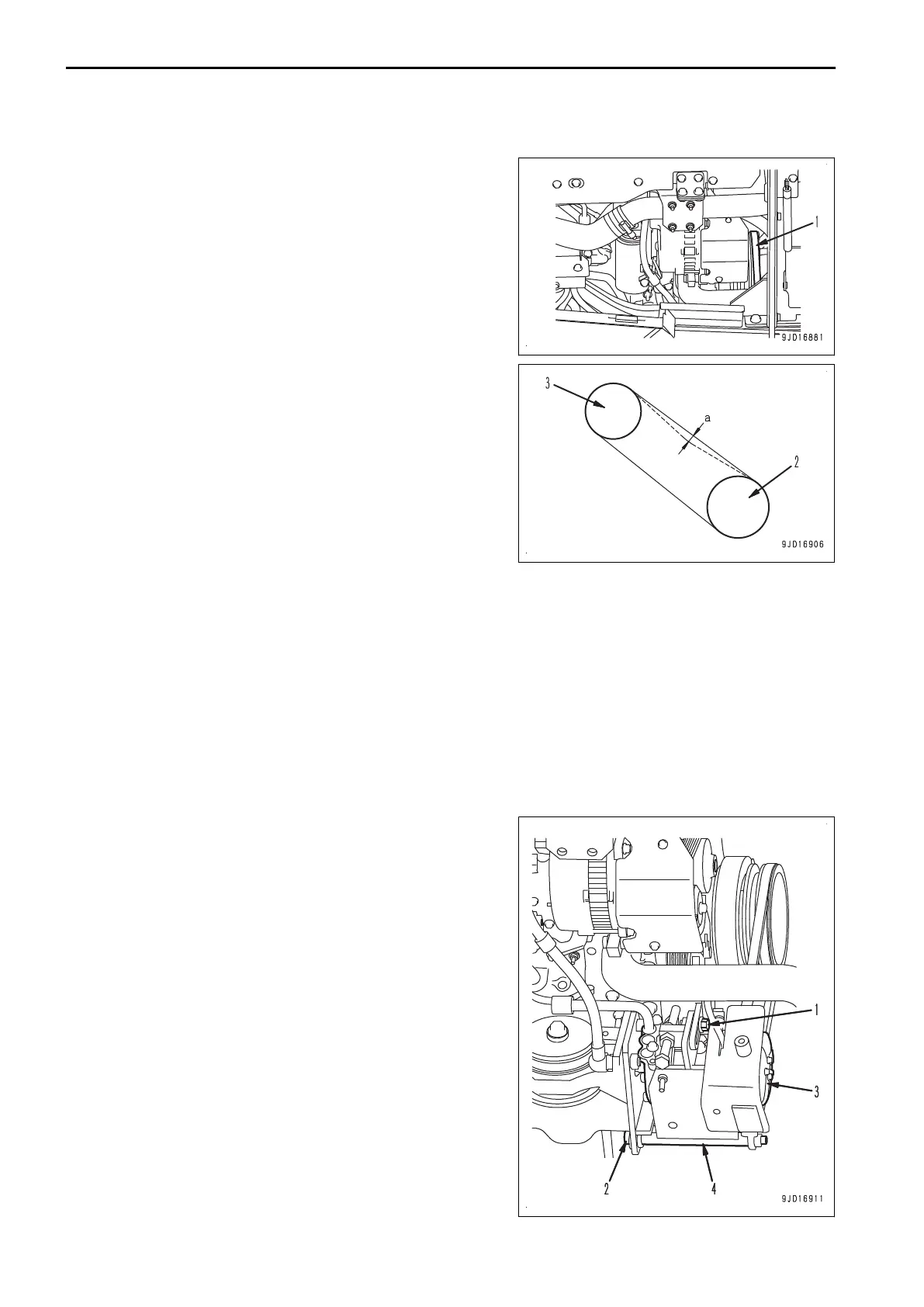

METHOD FOR CHECKING AIR CONDITIONER COMPRESSOR BELT

1.

Open the engine side cover on the left side of the ma-

chine.

2.

Check air conditioner compressor belt (1).

Press the middle point between air conditioner compressor

pulley

(2)

and

crankshaft pulley (3) with your thumb (ap-

proximately 98 N {10 kg}).

If deflection (a) is 11 to 15 mm, the belt tension is normal.

If the deflection is out of the standard range, adjust it into

the standard range.

When you use a belt tension gauge, the tension is normal

if it is in the range of 353 to 530 N {36 to 54 kg}.

METHOD FOR TESTING WHEN AIR CONDITIONER COMPRESSOR BELT IS RE-

PLACED

Press the middle

point between the compressor pulley and crankshaft pulley with your thumb (approximately

98 N {10 kg} ).

The standard deflection is 8 to 11.5 mm.

When you use a belt tension gauge, the tension is normal if it is in the range of 530 to 745 N {54 to 76 kg} .

REMARK

When the belt

is replaced with a new one, the above value is employed as the initial tension since a stronger

tension is required.

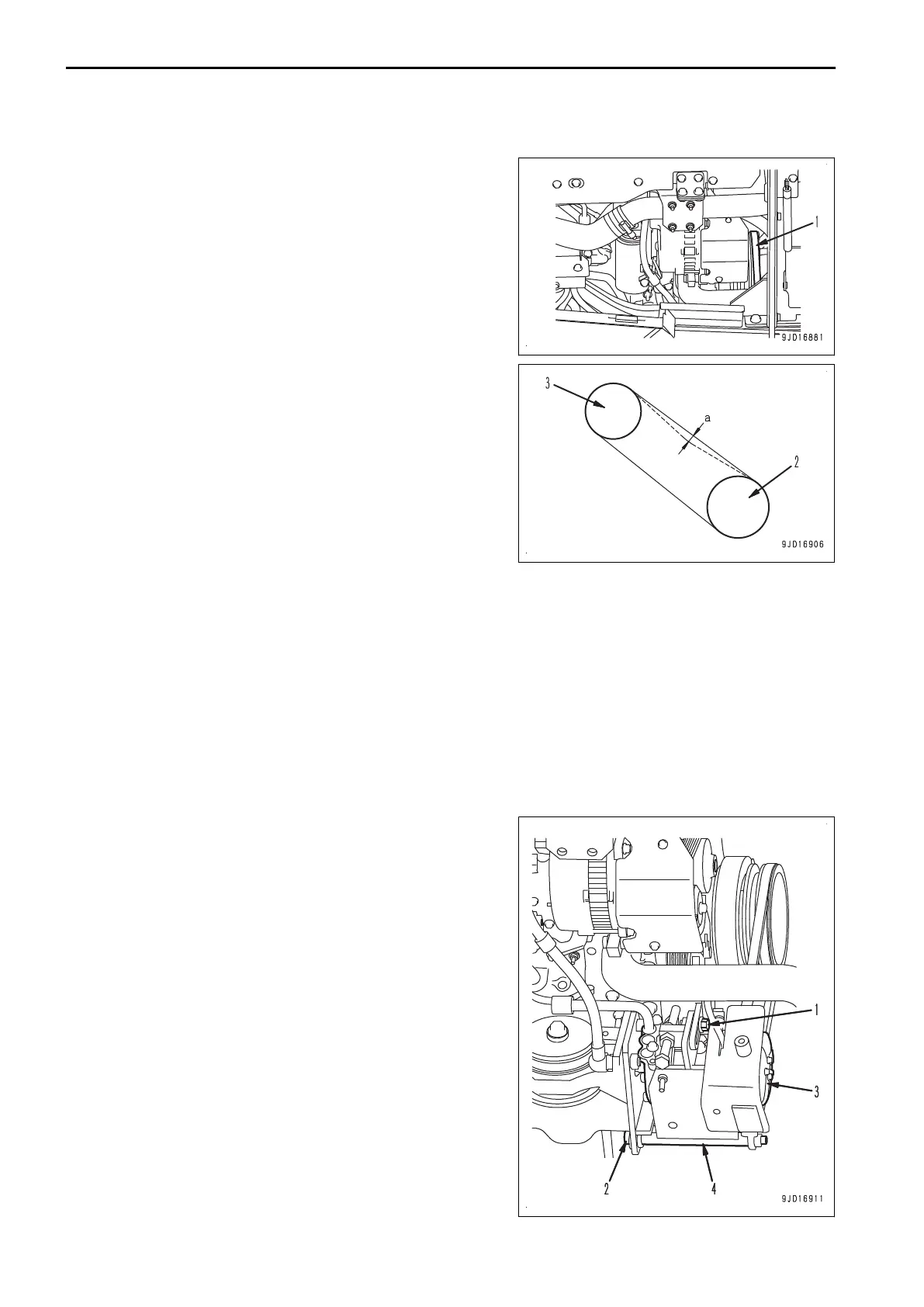

METHOD FOR ADJUSTING AIR CONDITIONER COMPRESSOR BELT

1.

Open the engine side cover on the right side of the ma-

chine.

2.

Loosen bolts (1) and (2).

REMARK

When the bolts

(1) and (2) are loosened, bracket (4) to

which compressor (3) is installed can move, using the

mounting position of bolt (2) as a fulcrum.

MAINTENANCE PROCEDURE MAINTENANCE

4-46

Loading...

Loading...