30

⿎

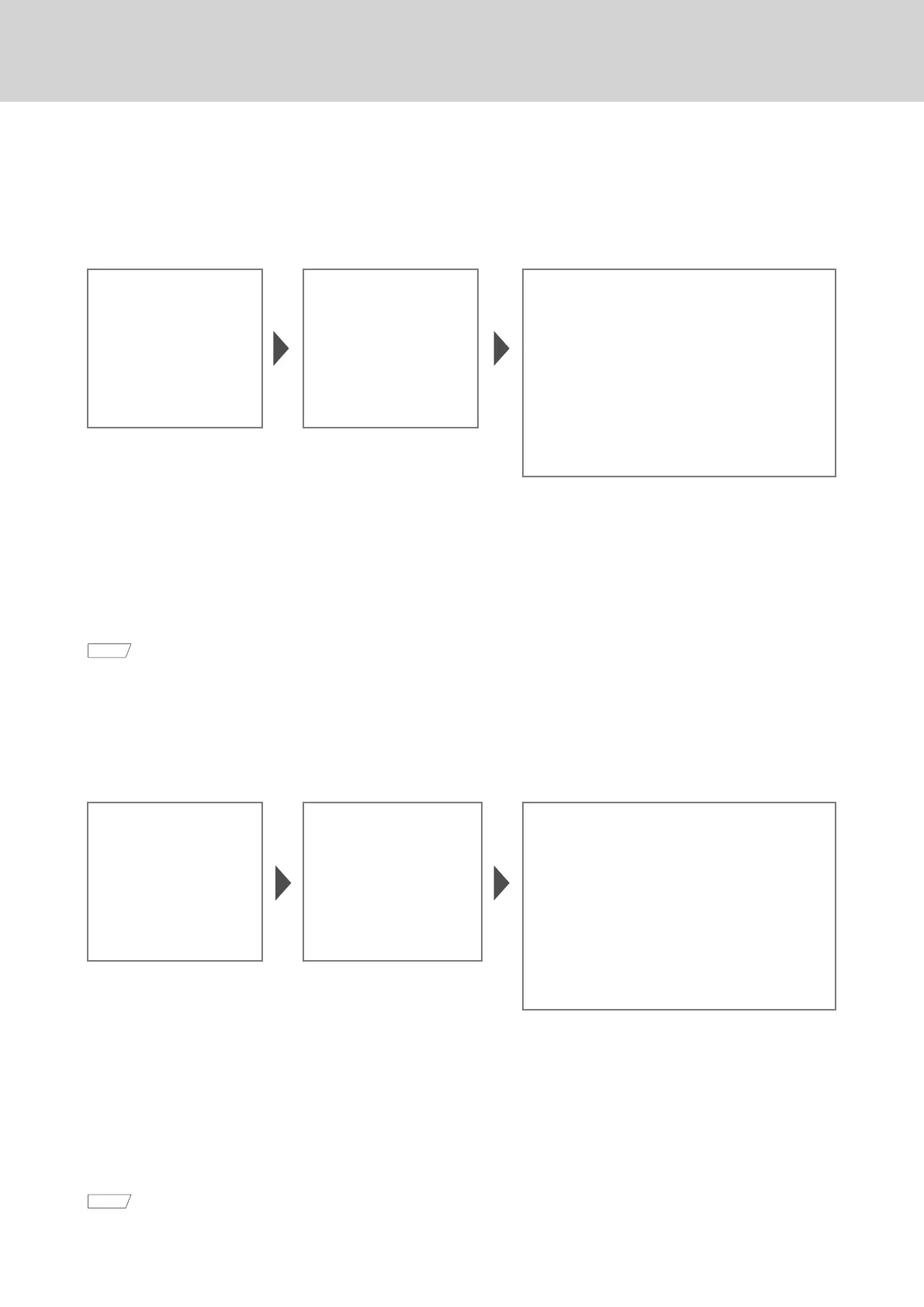

Measuring Reflected Colors

The flow of measurement is shown below.

The geometry of the CM-3600A conforms to CIE No.15, ISO 7724/1, ASTM E 1164, DIN 5033 Teil 7, and JIS

Z 8722 condition c (diffused illumination/perpendicular viewing system) standards, and offers both di:8° (SCI:

specular component included ; Total reflectance) and de:8° (SCE: specular component excluded ; Diffuse

reflectance) measurements.

① Light from the pulsed xenon lamps are diffused by

reflection from the inner surface of the integrating

sphere, and finally illuminate the specimen uniformly.

② a. The light reflected by the specimen surface at an angle of 8° to the normal to the surface

is received by the specimen-measuring optical system and guided to the sensor.

b. The diffused light in the integrating chamber is received by the illumination-

monitoring optical fiber and guided to the sensor.

③ The light from the specimen-measuring optical fiber and from the illumination-monitoring optical fiber

is divided into each wavelength component and projected onto the sensor array sections, which

convert the light into proportional currents and output the currents to the analog processing circuit.

Memo

• By using the outputs from the specimen-measuring sensor and the illumination-monitoring

sensor for calculations, compensation for slight differences in the spectral characteristics

and intensity of the illumination light is performed (double-beam system).

⿎

Measuring Transmitted Colors

The flow of measurement is shown below.

The geometry conforms to CIE No. 15, ASTM E1164, DIN 5033 Teil 7, and JIS Z 8722 condition g,

and offers di:0° (SCI: Total transmittance) and de:0° (SCE: Diffuse transmittance) measurements.

① Light from the pulsed xenon lamps are diffused by

reflection from the inner surface of the integrating sphere

and the surface of the white calibration plate covering the

reflectance measurement aperture, and finally illuminate the specimen in the transmittance chamber.

② a.

The light transmitted by the specimen is received by the specimen-

measuring optical system and guided to the sensor.

b. The diffused light in the integrating chamber is received by the illumination-

monitoring optical fiber and guided to the sensor.

③ The light from the specimen-measuring optical fiber and from the illumination-monitoring optical

fiber is divided into each wavelength component and projected onto the sensor array section, which

convert the light into proportional currents and output the currents to the analog processing circuit.

Memo

• By using the outputs from the specimen-measuring sensor and the illumination-monitoring

sensor for calculations, compensation for slight differences in the spectral characteristics

and intensity of the illumination light is performed (double-beam system).

lIIumination/Observation System

① Illumination

Light from xenon

lamps diffuse in the

integrating sphere

and illuminate the

specimen uniformly.

① Illumination

Light from xenon

lamps diffuse in the

integrating sphere

and illuminate

the specimen.

② Receiving

a. Light reflected

by the specimen

are received.

b. Light diffused in the

integrating sphere

are received.

② Receiving

a. Light passing through

the specimen

are received.

b. Light diffused in the

integrating sphere

are received.

③ Sensing

Light from the specimen-measuring and

illumination-monitoring optical fibers are

transmitted to sensors, where the light in the

wavelength range of 360 to 740 nm is divided

into 10 nm-pitch components and projected

onto the sensor array sections, which

convert the light intensity of each component

into proportional currents and output the

currents to the analog processing circuit.

③ Sensing

Light from the specimen-measuring and

illumination-monitoring optical fibers are

transmitted to sensors, where the light in the

wavelength range of 360 to 740 nm is divided

into 10 nm-pitch components and projected

onto the sensor array sections, which

convert the light intensity of each component

into proportional currents and output the

currents to the analog processing circuit.

Loading...

Loading...