2 Safety

10 of 48

KSB Delta Basic

1983.835/01-EN

▪ When taking the pressure booster system out of service always adhere to the

procedure described in the manual.

▪ Decontaminate pressure booster systems which handle fluids posing a health

hazard.

▪ As soon as the work has been completed, re-install and/or re-activate any safety-

relevant and protective devices. Before returning the product to service, observe

all instructions on commissioning.

▪ Make sure the pressure booster system cannot be accessed by unauthorised

persons (e.g. children).

▪ Prior to opening the device, pull the mains plug and wait for at least 10minutes.

2.8 Unauthorised modes of operation

Always observe the limits stated in the product literature.

The warranty relating to the operating reliability and safety of the pressure booster

system supplied is only valid if the equipment is used in accordance with its intended

use. (ðSection2.2,Page8)

2.9 Electromagnetic compatibility (EMC)

2.9.1 Interference emission requirements

The EN61800-3 EMC product standard is relevant for electric variable speed drives/

control systems. It specifies all pertinent requirements and refers to the relevant

generic standards for complying with the EMC Directive.

Frequency inverters are commonly used by operators as a part of a system, plant or

machine assembly. It should be noted that the operator bears all responsibility for

the final EMC properties of the equipment, plant or installation.

A prerequisite or requirement for complying with the relevant standards or the limit

values and inspection/test levels referenced by them is that all information and

descriptions regarding EMC-compliant installation be observed and followed.

In accordance with the EMC product standard, the EMC requirements to be met

depend on the purpose or intended use of the frequency inverter. Four categories

are defined in the EMC product standard:

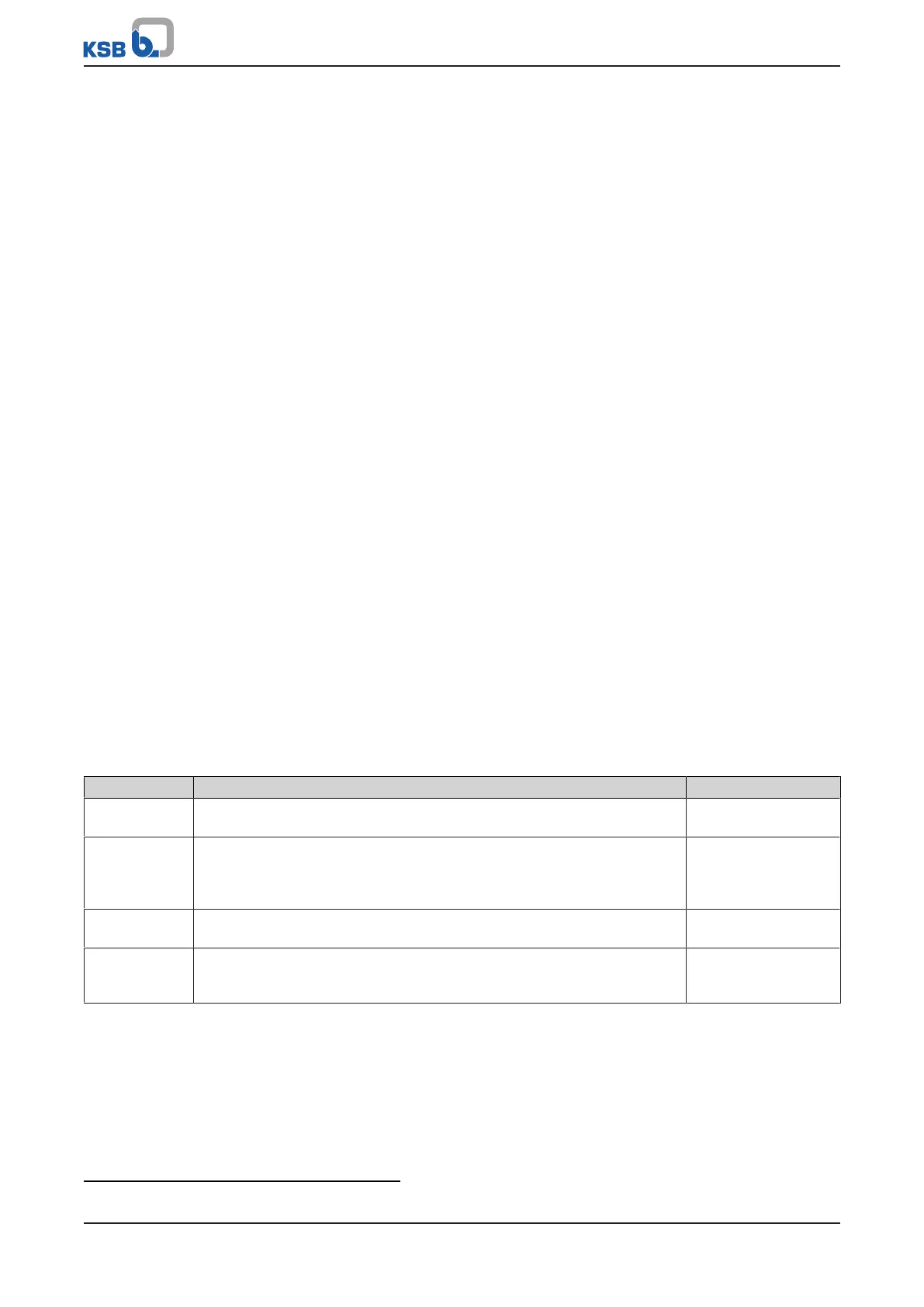

Table4: Categories of intended use

Category Definition Limits to EN55011

C1 Frequency inverters with a supply voltage under 1000V installed in the

first environment (residential and office areas).

Class B

C2 Frequency inverters with a supply voltage under 1000V installed in the

first environment (residential and office areas) that are neither ready to

be plugged in/connected nor are mobile and must be installed and

commissioned by specialist personnel.

Class A, Group 1

C3 Frequency inverters with a supply voltage under 1000V installed in the

second environment (industrial environments).

Class A, Group 2

C4 Frequency inverters with a supply voltage over 1000V and a nominal

current over 400A installed in the second environment (industrial

environments) or that are envisaged for use in complex systems.

No borderline/

boundary

1)

The following limit values and inspection/test levels must be complied with if the

generic standard on interference emissions applies:

1) An EMC plan must be devised.

Loading...

Loading...