5 Installation at Site

20 of 48

KSB Delta Basic

1983.835/01-EN

NOTE

To prevent the transmission of piping forces and solid-borne noise, installing

expansion joints with length-limiters is recommended.

ü The pressure booster system’s packaging has been removed.

ü A suitable installation site has been selected that meets the requirements.

ü Sufficient clearance in all directions is provided for servicing work.

1. Make sure that there is sufficient space for the pressure booster system.

2. Place the pressure booster system in its correct installation position.

5.3 Connecting the piping

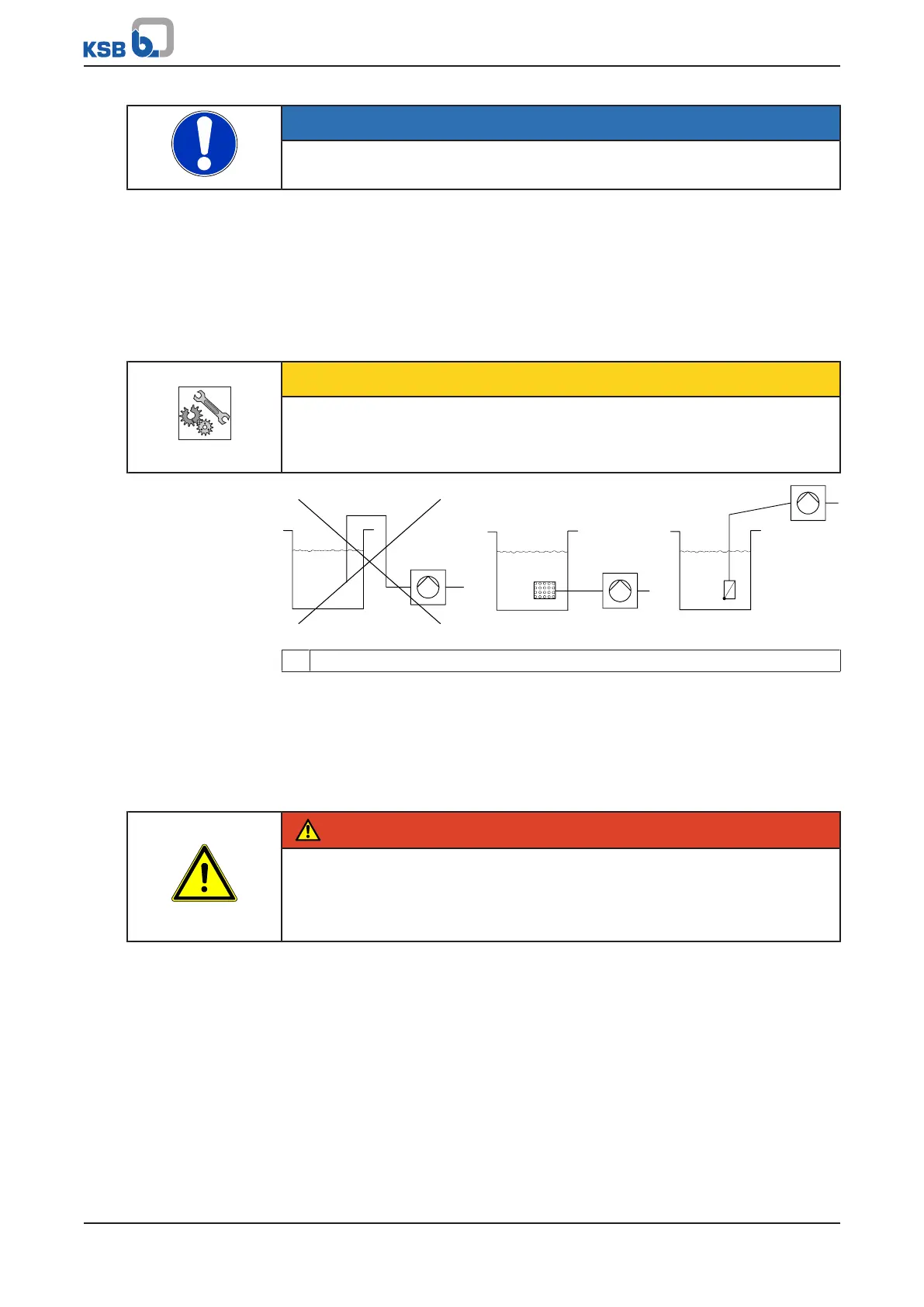

CAUTION

Air pockets in suction line

Pressure booster system cannot prime!

▷ Lay the pipe with a continuously rising slope.

Fig.4: Correct piping connection

1 Suction lift operation

1. Mechanically support the suction head line on site to provide for absorption of

mechanical forces.

2. Install the piping without transmitting any stresses and strains.

3. Connect the piping to the distribution lines on the inlet side and discharge side.

5.3.1 Fitting an expansion joint (optional)

DANGER

Sparks and radiant heat

Fire hazard!

▷ Take suitable precautions to protect the expansion joint if any welding work is

carried out.

Loading...

Loading...