8 Servicing/Maintenance

34 of 48

KSB Delta Basic

1983.835/01-EN

14. Fit and tighten the screw.

15. Close the drain plugs of the pump. Properly dispose of the fluid collected.

16. Slowly open the shut-off valve and check for any leakage.

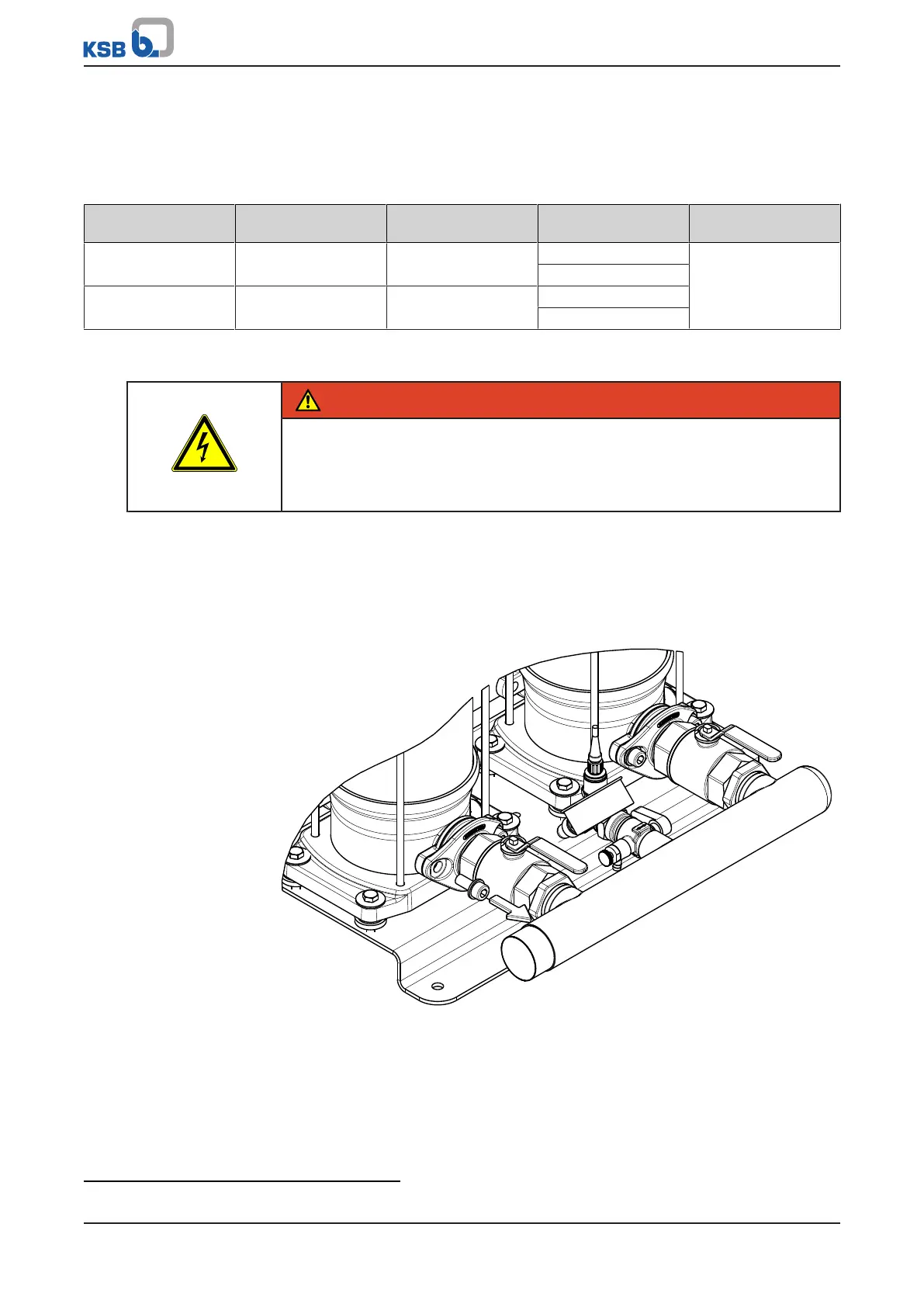

Table13: Spare parts for servicing non-return valves, per pump

Material number Description Non-return valve O-rings O-ring lubricant

(non-water soluble)

71630405 ER non-return valve

DN32

Watts Industries

IN 032 DN 32

1xEriks 12711456 Molykote® G-5511

3)

2xEriks 12711457

71630410 ER non-return valve

DN50

Watts Industries

IN 050 DN 50

1xEriks 12192264

2xEriks 12711459

8.2.5 Mounting the manifold in a mirrored position

DANGER

Voltage at the pressure booster system

Danger to life!

▷ Prior to opening the device, wait at least 10minutes for any residual voltage to

dissipate.

1. De-energise the pump set and secure it against unintentional start-up. Comply

with the local regulations.

2. Close the shut-off valves in the discharge line and suction line of the pressure

booster system.

3. Place a suitable container under the drain connections.

4. Open the drain connections. To do so, observe the pump's operating manual.

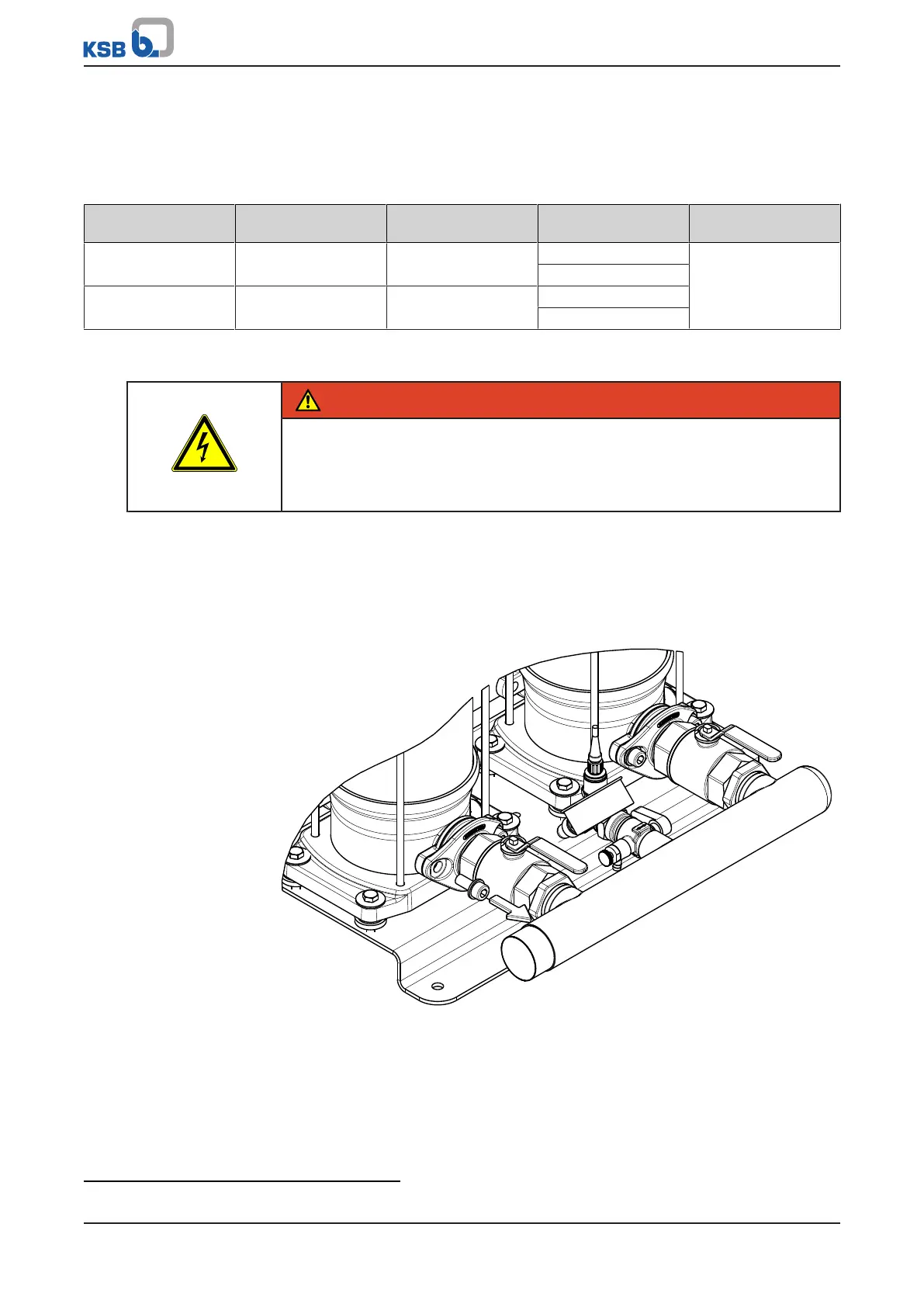

Fig.15: Removing the bolts

5. Remove the tie bolts between the two oval flanges and the pumps.

3) Sealant for taps

Loading...

Loading...