4 Description

21 of 92

KSB Delta Macro

1983.843/04-EN

4.7 Noise characteristics

The pressure booster system is available with different numbers and sizes of pumps.

For the noise characteristics refer to the operating manual of the pump set. To

calculate the expected total sound pressure level, add a defined value to the

individual pump set’s expected sound pressure level.

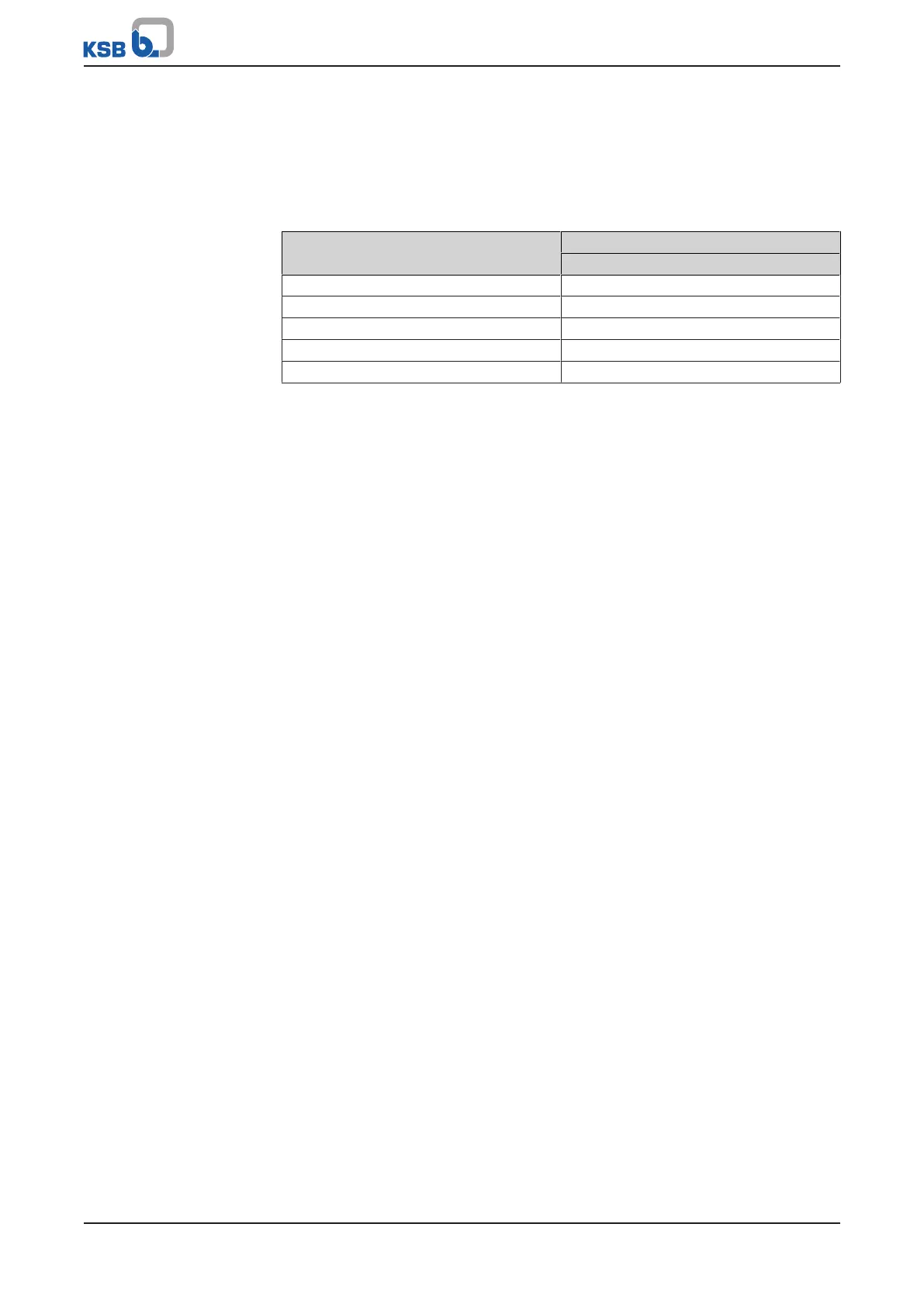

Table9: Values for calculating the total expected sound pressure level

Number of pump sets Value

dB(A)

2 + 3

3 + 4,5

4 + 6

5 + 7

6 + 7,5

Example Pressure booster system with 4 pump sets (value: + 6dB(A))

Single pump = 48dB(A)

48dB(A) + 6dB(A) = 54dB(A)

The expected total sound pressure level of 54dB(A) may develop when all 4 pump

sets are running under full-load conditions.

4.8 Scope of supply

Depending on the model, the following items are included in the scope of supply:

Pressure booster system

▪ Two to six vertical high-pressure centrifugal pumps

▪ Discharge-side, direct-flow membrane-type accumulator, approved for drinking

water

▪ 1 check valve and 2 shut-off valves per pump set to DIN/DVGW

▪ Pressure transmitter on the suction side and discharge side

▪ Pressure gauge

▪ Powder-coated / epoxy resin-coated steel baseplate

For Movitec 2B, Movitec 4B, Movitec 6B, Movitec 10B and Movitec 15C:

▪ With oval flange

▪ Pressure booster system with rubber feet

For Movitec 25B, Movitec 40B, Movitec 60B, Movitec 90B and Movitec 125B:

▪ With round flange

▪ Pressure booster system with level-adjustable feet and rubber pads

Control unit

▪ IP54 enclosure

▪ Control panel (display, keys, LEDs, service interface)

▪ Transformer for control voltage

▪ Motor protection switch per pump

▪ Lockable master switch (repair switch)

▪ Terminal strip/terminals with identification for all connections

▪ Circuit diagram and list of electric components

▪ Connection for analog or digital dry running protection equipment

▪ Remote ON/OFF input

Loading...

Loading...