6 Commissioning/Start-up/Shutdown

6.1 Commissioning/start-up

6.1.1 Prerequisites for commissioning/start-up

Before starting up the pump set make sure that the following requirements are met:

▪ The pump set has been properly connected to the electric power supply and is

equipped with all protection devices.

▪ The pump has been primed with the fluid to be handled. (⇨ Section 6.1.4 Page

39)

▪ The direction of rotation has been checked. (⇨ Section 5.9 Page 36)

▪ All auxiliary connections required are connected and operational.

▪ The lubricants have been checked.

▪ After prolonged shutdown of the pump (set), the activities described in (⇨

Section 6.4 Page 45) have been carried out.

6.1.2 Filling in lubricants

Fill the bearing bracket with lubricating oil.

Oil quality see (⇨ Section 7.2.3.1.2 Page 49)

Oil quantity see (⇨ Section 7.2.3.1.3 Page 49)

Filling t h e c onstant level o i l er with lubri c a t i ng oil (for oi l - l ubricated

b

earings o n l y )

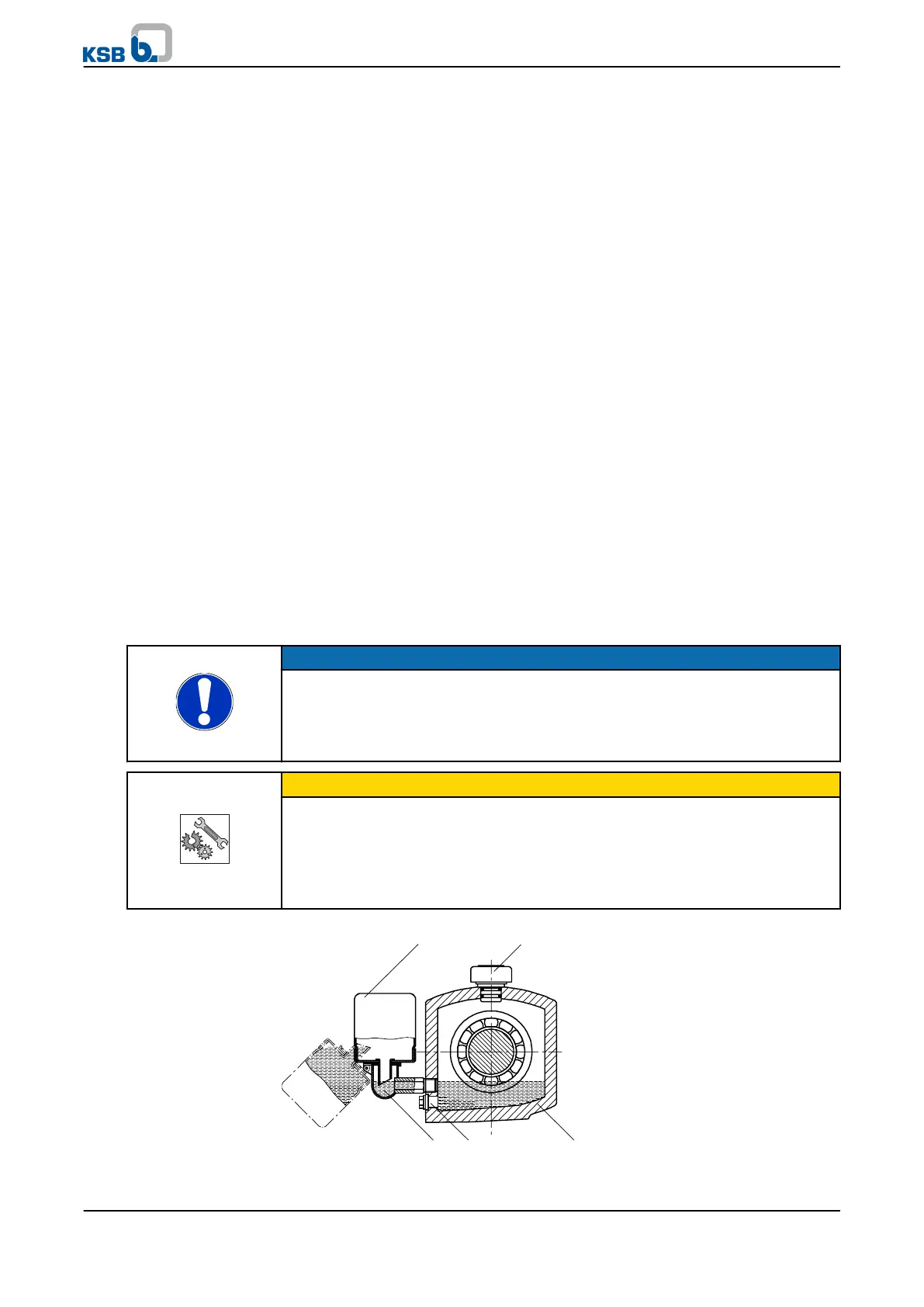

✓ The constant level oiler is screwed into the upper tapping hole of the bearing

bracket.

NOTE

If no constant level oiler is provided on the bearing bracket, the oil level can be read in

the middle of the oil level sight glass arranged at the side of the bearing bracket

(optional).

Figure 4H: If access to the vent plug is difficult or impossible, the oil can be filled in

through the connection elbow of the constant level oiler.

CAUTION

Insufficient lubricating oil in the reservoir of the constant-level oiler

Damage to the bearings!

▷ Regularly check the oil level.

▷ Always fill the oil reservoir completely.

▷ Keep the oil reservoir properly filled at all times.

Fig. 18: Bearing bracket with constant level oiler

Oil-lubricated bearings

6 Commissioning/Start-up/Shutdown

38 of 78

KWP

Loading...

Loading...