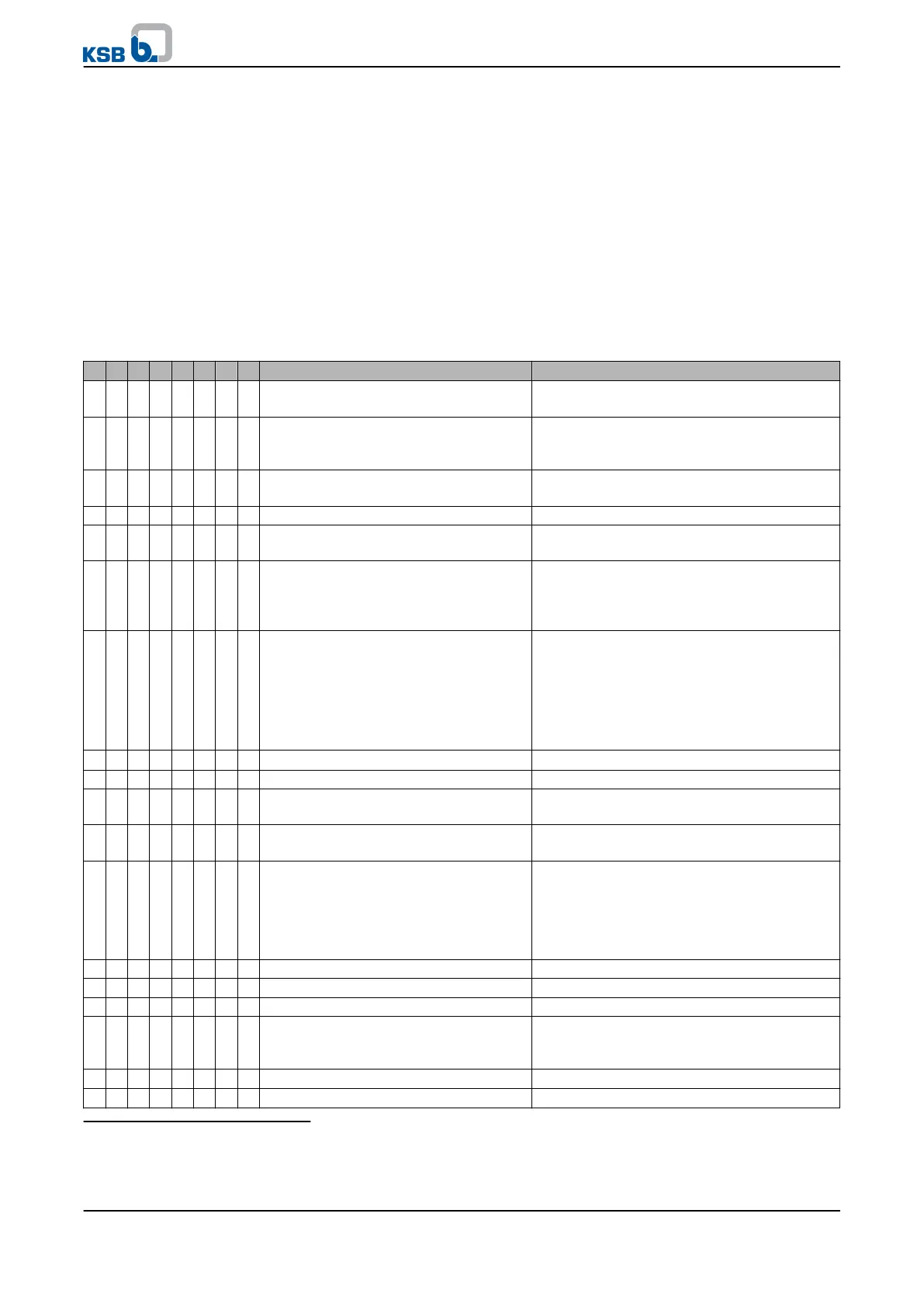

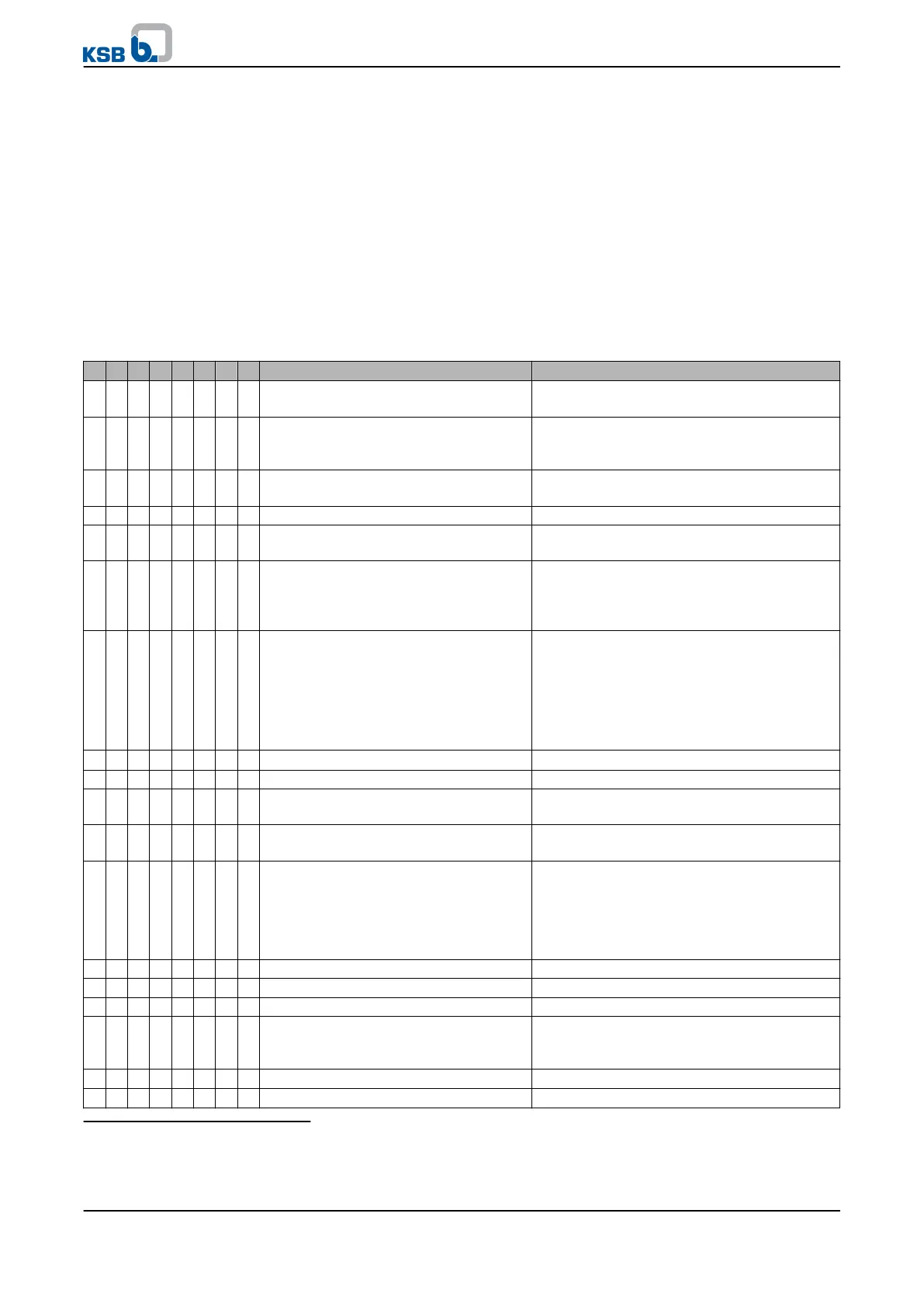

8 Trouble-shooting

Pump delivers insufficient flow rate

Motor overload

Excessive pump discharge pressure

Excessive bearing temperature

Leakage at the pump

Excessive leakage at the shaft seal

Vibrations during pump operation

Excessive rise of temperature inside the pump

Table 27: Trouble-shooting

A B C D E F G H Possible cause

Remedy

22)

X Pump delivers against an excessively

high discharge pressure.

Re-adjust to duty point.

x Excessively high back pressure. Check plant for impurities.

Fit a larger impeller.

23)

Increase the speed (turbine, I.C. engine).

X X X Pump or piping are not completely

vented or primed.

Vent and/or prime.

X Supply line or impeller clogged. Remove deposits in the pump and/or piping.

X Formation of air pockets in the piping. Modify the piping.

Fit a vent valve.

X X X Pump is warped or sympathetic

vibrations in the piping.

Check pipeline connections and secure fixing

of pump; if required, reduce the distances

between the pipe clamps.

Fix the pipelines using anti-vibration material.

X X X Suction head is too high,

NPSH

available

(positive suction head) is too

low.

Check/alter liquid level.

Fully open the shut-off valve in the suction

line.

Change suction line if the friction losses in the

suction line are too high.

Check any strainers installed/suction opening.

Observe permissible speed of pressure fall.

X

Increased axial thrust.

23)

Correct rotor adjustment.

X Air intake at the shaft seal. Fit new shaft seal.

X Wrong direction of rotation. Interchange two of the phases of the power

supply cable.

X X Motor is running on two phases only. Replace the defective fuse.

Check the electric cable connections.

X Speed is too low.

- Pump operation with frequency

inverter

- Pump operation without frequency

inverter

- Increase voltage/frequency at the frequency

inverter in the permissible range.

- Check the voltage.

X Defective bearing(s) Fit new bearing(s).

X X X Flow rate is too low. Increase the minimum flow rate.

X X Wear of internal pump parts Replace worn components by new ones.

X Density or viscosity of the fluid pumped

is higher than stated in the purchase

order.

Contact KSB.

X Use of unsuitable materials. Change the material combination.

X X Speed is too high.

Reduce speed.

23)

A

B

C

D

E

F

G

H

22)

Pump pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

23)

Contact KSB.

8 Trouble-shooting

KWP

69 of 78

Loading...

Loading...