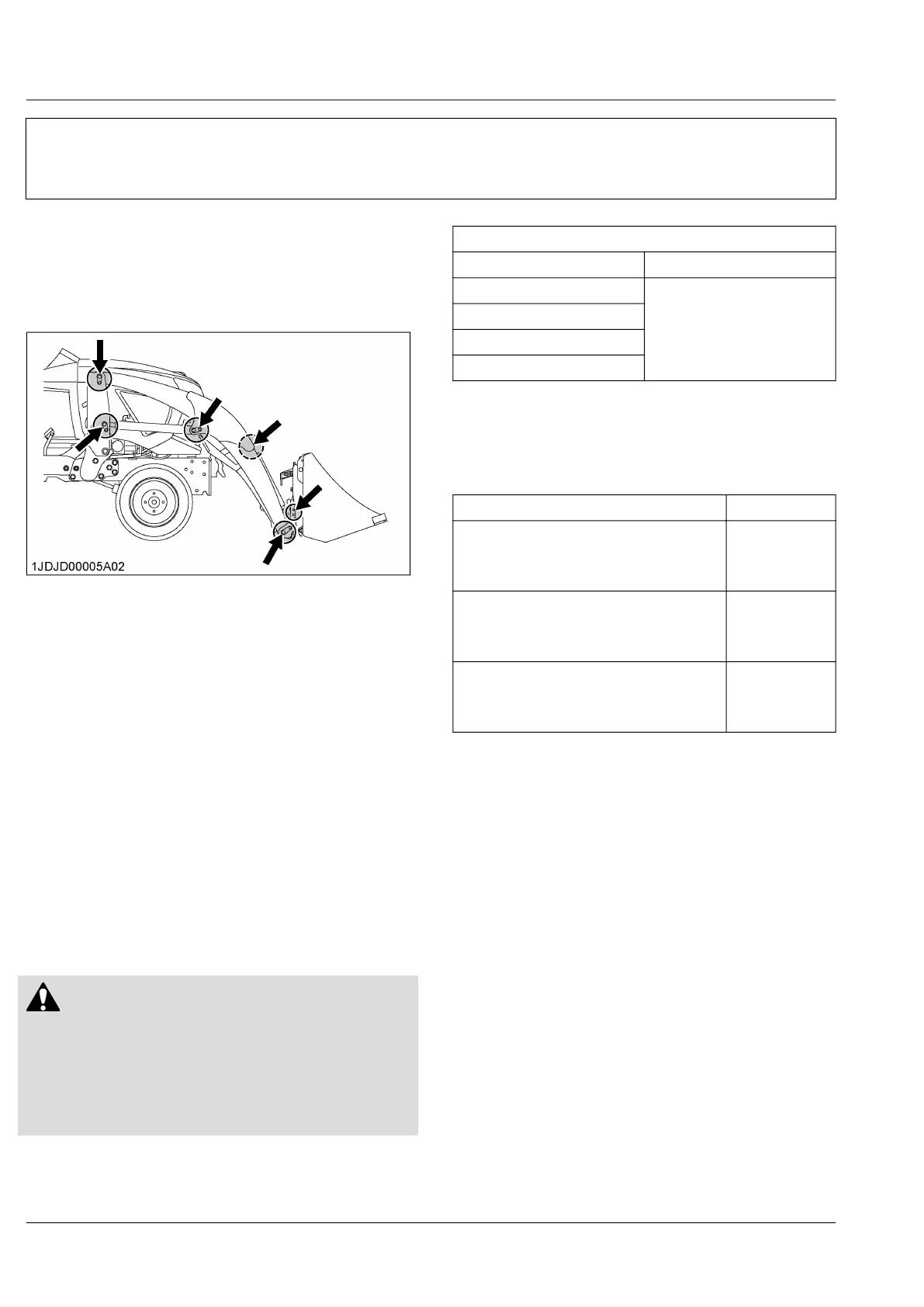

PRE-OPERATION CHECK OF THE LOADER

LUBRICATION BEFORE

OPERATING THE LOADER

Lubricate all grease fittings with SAE multipurpose

grease, including the control arm.

CHECKING THE

TRANSMISSION FLUID

IMPORTANT :

• To check the tractor transmission fluid level,

lower the bucket to the ground and lower the 3-

point hitch.

1. Check the transmission fluid level of the tractor.

2. Add the transmission fluid if necessary.

Refer to the tractor operator's manual for

instructions and proper transmission fluid.

3. Repeat check of the transmission fluid after purging

air from the loader system.

4. Then, add the transmission fluid if necessary.

WEIGHT OF THE IMPLEMENTS

AS THE REAR BALLAST

WARNING

To avoid personal injury or death:

• For tractor stability and operator's safety, add

the rear ballast to the rear of the tractor in the

form of 3-point counter weight and the rear

wheel ballast. The amount of the rear ballast will

depend on the application.

Implement as Counter Weight

Backhoe Approx. 266 kg (586 lbs.)

Box Blade

Approx. 190 kg (420 lbs.)

Rear Blade

Rotary Tiller

Ballast Box

1. Liquid ballast in the rear tires

See 2. Rear ballast on page 91 .

Liquid weight per tire (75 percent filled)

Tire sizes 26x12.00-12

Slush free at -10 ℃ (14 ℉)

Solid at -30 ℃ (-22 ℉)

[Approx. 1 kg (2 lbs.) CaCl2 per 4 L (1 gal) of

water]

45 kg

(99 lbs.)

Slush free at -24 ℃ (-11 ℉)

Solid at -47 ℃ (-52 ℉)

[Approx. 1.5 kg (3.5 lbs.) CaCl2 per 4 L (1 gal)

of water]

50 kg

(110 lbs.)

Slush free at -47 ℃ (-52 ℉)

Solid at -52 ℃ (-62 ℉)

[Approx. 2.25 kg (5 lbs.) CaCl2 per 4 L (1 gal)

of water]

56 kg

(123 lbs.)

CHECK OF THE TIRE

INFLATION BEFORE

OPERATING THE LOADER

Make sure that the tractor tires are properly inflated.

See 1. Inflation pressure of tires on page 89.

PRE-OPERATION CHECK OF THE LOADER

LUBRICATION BEFORE OPERATING THE LOADER

Loading...

Loading...