PERIODIC SERVICE32

BChecking Amount of Fuel and Refueling

To avoid personal injury:

A Handle fuel carefully. If the engine is running,

do not fill the fuel tank. If engine is hot, let

engine cool several minutes before adding fuel.

Do not smoke while filling the fuel tank or

servicing the fuel system. Fill fuel tank only to

bottom of filler neck.

Check the fuel level. Take care that the fuel tank does not

become empty.

A Use Diesel Fuel Only

1. Use No.2 diesel fuel.

2. Use No.1 diesel fuel if the temperature is below -10

(14 ).

3. Always use a strainer when refueling to prevent fuel

injection pump contamination.

A No.2-D is a distillate fuel of lower volatility for engines

in industrial and heavy mobile service.

(SAE J313 JUN87)

Grade of Diesel Fuel Oil according to ASTM D975

BChecking and Cleaning Radiator Screen

and Bonnet Screen to Prevent

Overheating

To avoid personal injury:

A Be sure to stop the engine and remove the key

before cleaning.

A The air intake area must be clear of debris to prevent

the engine from overheating.

Daily or after every 5 hours of operation, check to be sure

the radiator screen and the bonnet screen are clean.

Dirt or chaff on the radiator screen or bonnet screen

decrease cooling performance.

1. Remove the radiator screen and the bonnet screen,

and remove all foreign material.

2. Remove the dust from between the fins and the tube.

3. Tighten the fan drive belt as necessary. For this, refer

to "EVERY 100 HOURS" in "PERIODIC SERVICE"

section.

Fuel tank capacity 61 L (16.1 U.S.gals.)

Flash point

()

Water and

Sediment,

volume

%

Carbon

Residue on,

10 percent

Residuum,

%

Ash, weight

%

Min Max Max Max

52 (125) 0.05 0.35 0.01

Distillation

Temperatures

()

90% Point

Viscosity

Kinematics

cSt or mm /s

at 40

Viscosity

Saybolt, SUS

at 37.8

(100 )

Min Max Min Max Min Max

282

(540)

338

(640)

1.9 4.1 32.6 40.1

Sulfur, weight

%

Copper strip

Corrosion

Cetane

Number

Max Max Min

0.50 No.3 40

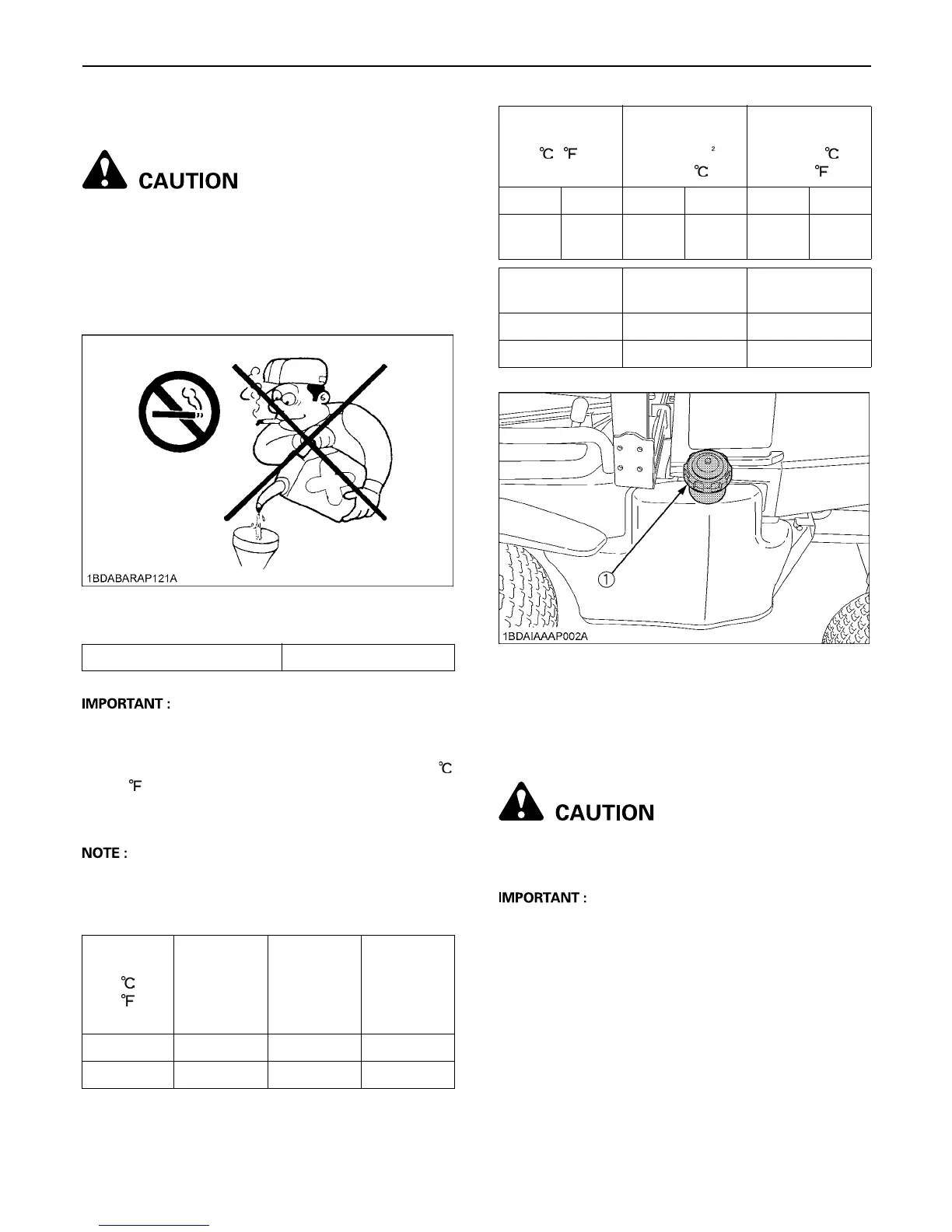

(1) Fuel port

Loading...

Loading...