PERIODIC SERVICE48

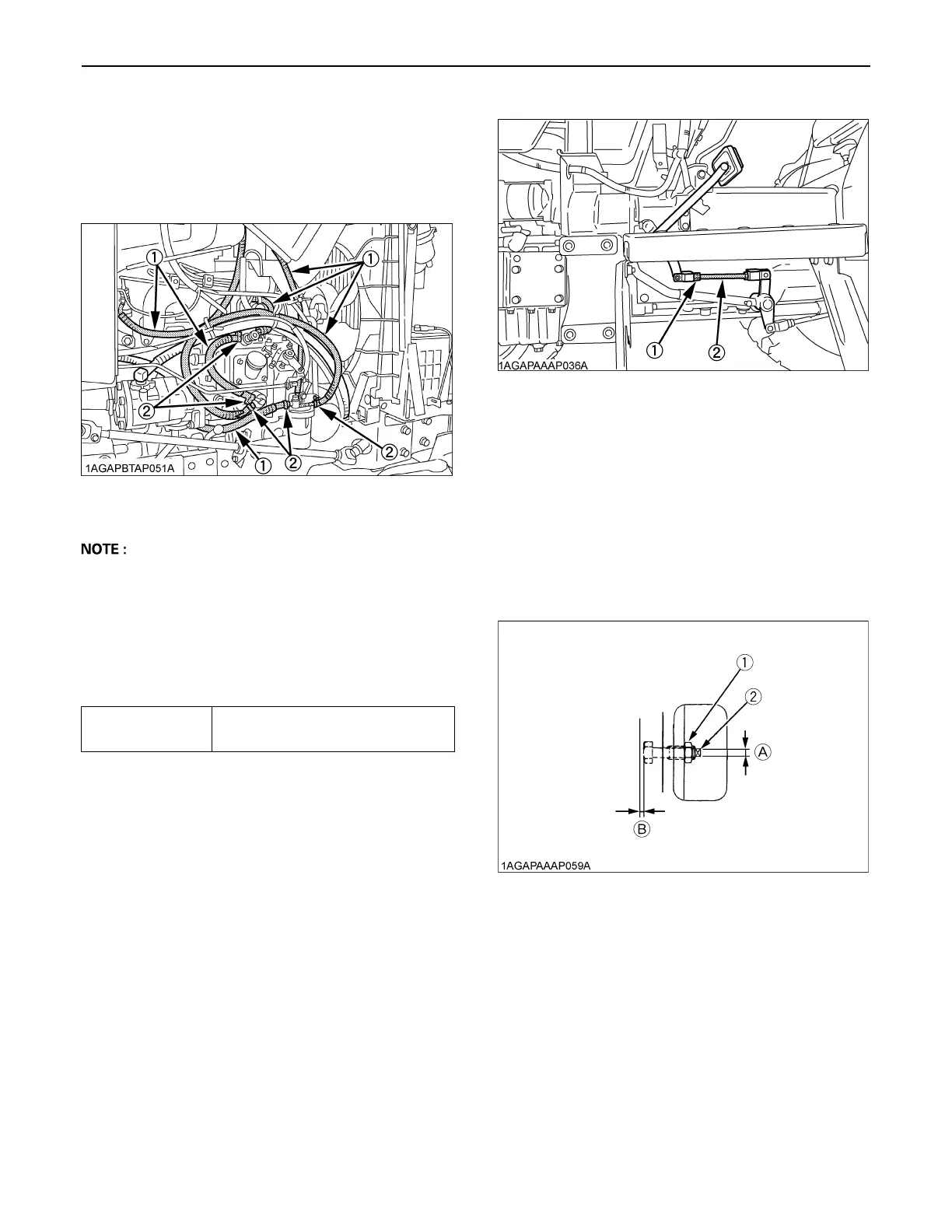

BChecking Fuel Line

1. Check to see that all lines and hose clamps are tight

and not damaged.

2. If hoses and clamps are found worn or damaged,

replace or repair them at once.

A If the fuel line is removed, be sure to properly bleed the

fuel system.

(See "Bleeding Fuel System" in "SERVICE AS

REQUIRED" in "PERIODIC SERVICE" section.)

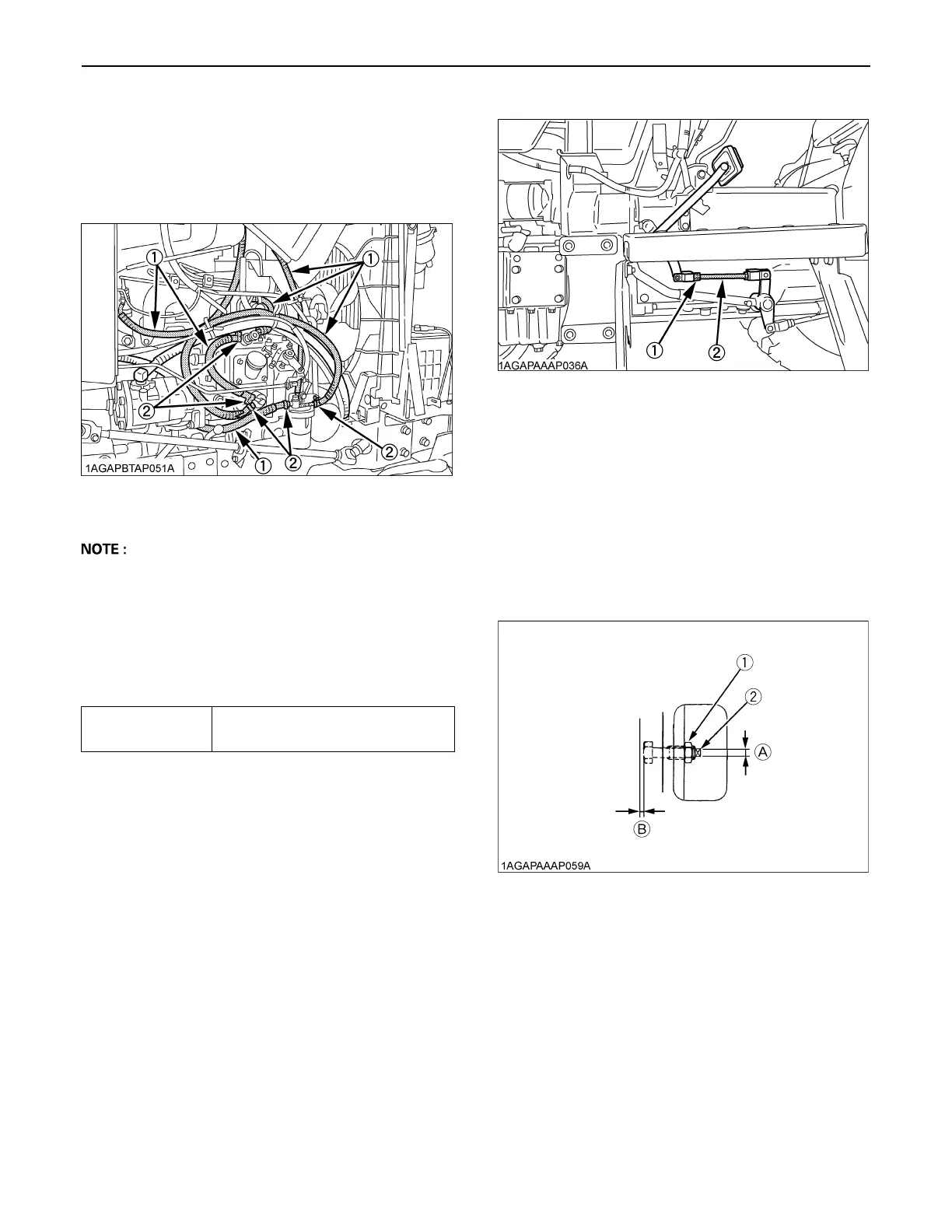

BAdjusting Clutch Pedal

C Adjusting procedure [with single clutch]

[L3200]

1. Stop the engine and remove the key.

2. Slightly depress the clutch pedal and measure free

travel at the top of pedal stroke.

3. If adjustment is needed, loosen the lock nut and turn

the clutch rod to adjust the rod length within

acceptable limits.

4. Retighten the lock nut.

C Adjusting procedure [with Dual Clutch]

[L3800]

1. At first adjust clutch play, same as with single disc

clutch.

2. Remove the cover located on the right side of flywheel

housing case.

3. Loosen the lock nut, tighten the adjust bolt by using 6

mm spanner until head of the bolt contacts pressure

plate slightly.

Make 3/4 turn counterclockwise to give 0.9 to 1.0 mm

clearance.

4. Tighten the lock nut, holding the adjusting bolt.

5. Turn the flywheel to adjust the clearance of other

adjusting bolts. (three bolts)

6. Repeat step (3) and readjust free travel of clutch pedal

if necessary.

(1) Fuel lines

(2) Clamp bands

Proper clutch

pedal free travel

20 to 30 mm on the pedal

(1) Lock nut

(2) Clutch rod

(1) Lock nut

(2) Adjusting bolt

(A) 6 mm

(B) 0.9 to 1.0 mm

Loading...

Loading...