8. CYLINDER/PISTON

8-1

SUPER8 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder and piston can be serviced with the engine installed in the frame.

• After disassembly, clean the removed parts and dry them with compressed air before inspection.

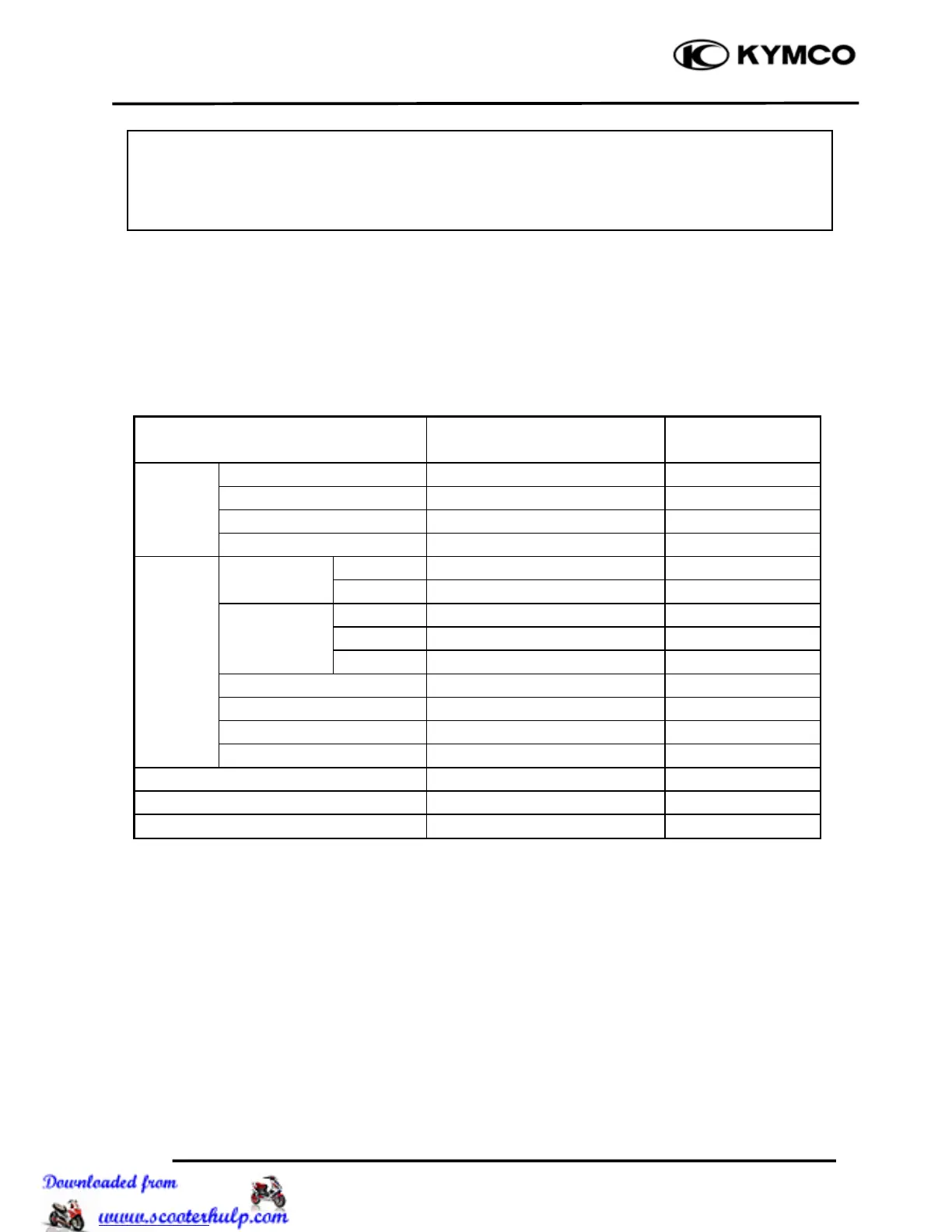

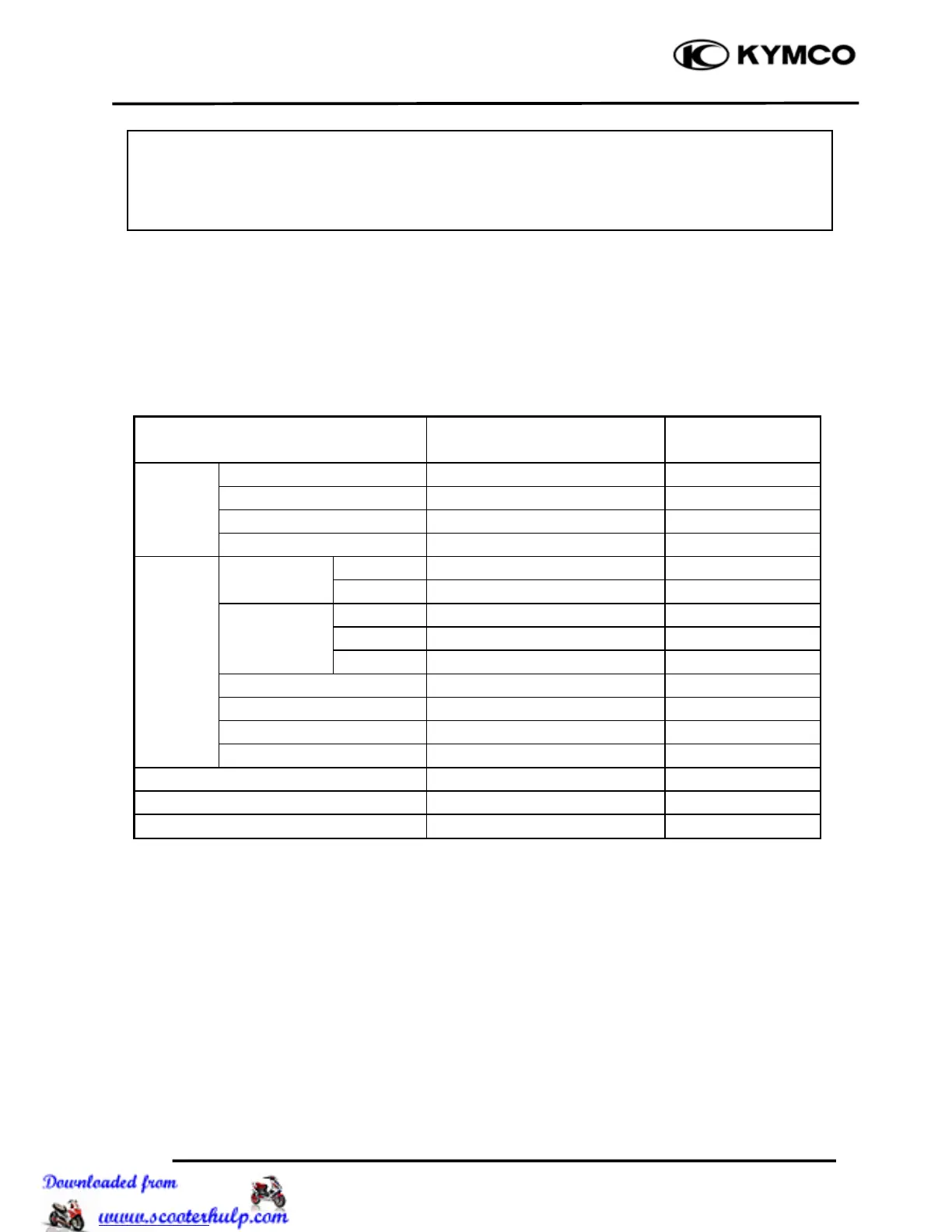

SPECIFICATIONS

Item

Standard (mm) Service Limit (mm)

I.D. 50.00-50.01

Warpage ⎯ 0.05

Cylindricity ⎯ 0.05

True roundness ⎯ 0.05

Rin

Oil side rail 0.20-0.70 ⎯

Piston O.D. 49.97-49.990 49.9

Piston O.D. measuring 9mm from bottom of skirt ⎯

Piston-to-cylinder clearance 0.010-0.040 0.1

Piston pin hole I.D. 13.002-13.008 13.04

Piston pin O.D 12.994-13.000 12.96

Piston-to-piston pin clearance 0.002-0.014 ⎯

Connecting rod small end I.D. bore 13.016-13.034 13.06

TROUBLESHOOTING

• When hard starting or poor performance at low speed occurs, check the crankcase breather for

white smoke. If white smoke is found, it means that the piston rings are worn, stuck or broken.

Compression too low or uneven

compression Excessive smoke from exhaust muffler

• Worn, stuck or broken piston rings • Worn or damaged piston rings

• Worn or damaged cylinder and piston • Worn or damaged cylinder and piston

Compression too high Abnormal noisy piston

• Excessive carbon build-up in combustion • Worn cylinder, piston and piston rings

chamber or on piston head

• Worn piston pin hole and piston pin

SERVICE INFORMATION.......................8-1 PISTON REMOVAL.................................8-2

TROUBLESHOOTING..............................8-1 PISTON INSTALLATION........................8-6

CYLINDER REMOVAL ...........................8-2 CYLINDER INSTALLATION .................8-6

Cylinde

Loading...

Loading...