7. CYLINDER HEAD (2-STROKE)/

CYLINDER/PISTON

SERVICE INFORMATION (4-STROKE)

GENERAL INSTRUCTIONS

• The cylinder and piston can be serviced with the engine installed in the frame.

• Before disassembly, clean the engine to prevent dust from entering the engine.

• Remove all gasket material from the mating surfaces.

• Do not use a driver to pry between the cylinder and cylinder head, cylinder and crankcase.

• Do not damage the cylinder inside and the piston surface.

• After disassembly, clean the removed parts before inspection. When assembling, apply the

specified engine oil to movable parts.

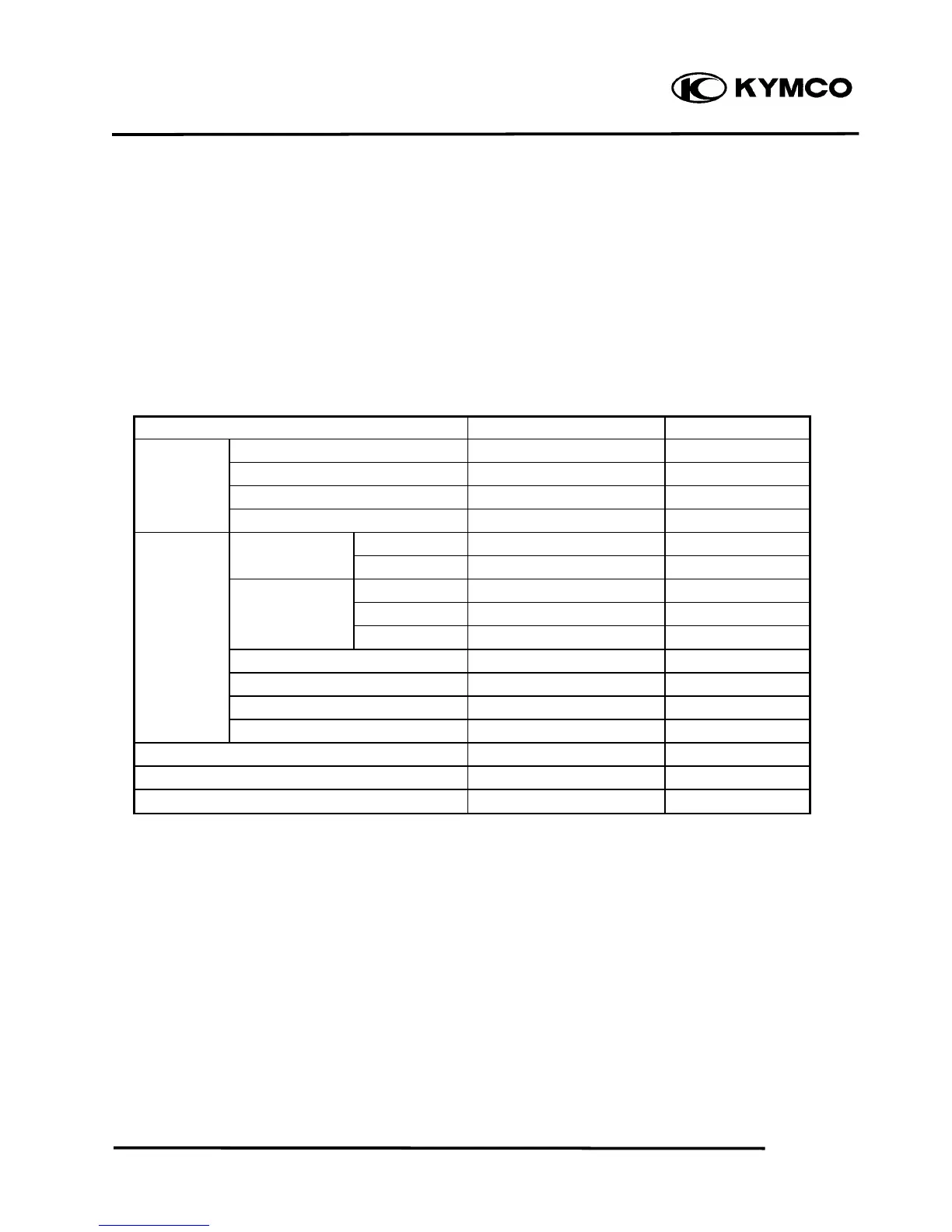

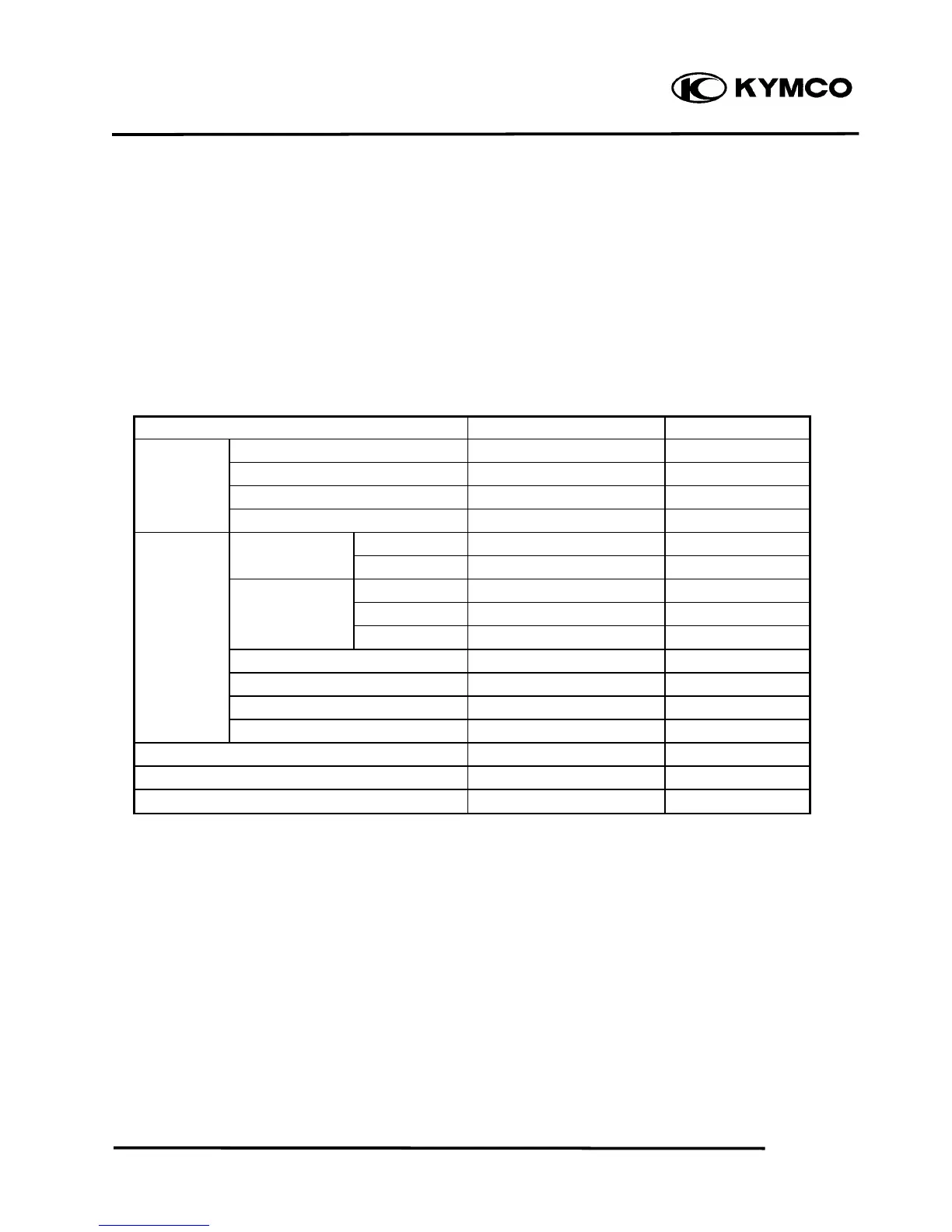

SPECIFICATIONS

Standard (mm) Service Limit (mm)

I.D. 39.0039.01 39.1

Warpage 0.05

Cylindricity 0.05

True roundness 0.05

Ring-to-groove Top 0.0150.055 0.09

clearance Second 0.0150.055 0.09

Top 0.150.3 0.5

Piston, Ring end gap Second 0.30.45 0.65

piston ring Oil ring 0.20.7 0.9

Piston O.D. 38.97538.99 38.9

Piston O.D. measuring position 4.5mm from bottom of skirt

. Piston-to-cylinder clearance 0.0100.040 0.1

Piston pin hole I.D. 13.00213.008 13.04

Piston pin O.D 12.99413.000 12.96

Piston-to-piston pin clearance 0.0020.014 0.02

Connecting rod small end I.D. bore 13.01613.034 13.06

TROUBLESHOOTING

• When hard starting or poor performance at low speed occurs, check the crankcase breather for

white smoke. If white smoke is found, it means that the piston rings are worn, stuck or broken.

Compression too low or uneven

compression Excessive smoke from exhaust muffler

• Worn, stuck or broken piston rings • Worn or damaged piston rings

• Worn or damaged cylinder and piston • Worn or damaged cylinder and piston

Compression too high Abnormal noisy piston

• Excessive carbon build-up in combustion • Worn cylinder, piston and piston rings

chamber or on piston head

• Worn piston pin hole and piston pin

Loading...

Loading...