12 / 30 Puridest Distillation Apparatus 09/2020

9 Maintenance, Service and Trouble Shooting

Caution:

Prior to maintenance and service on the unit let the Distillation Apparatus cool down!

Danger of burns!

Caution:

Before opening the Distillation Apparatus as well as prior to cleaning, separate the unit

from the mains supply! (Pull the plug or switch off main switch).

Danger of electrical shock!

Descaling

9.1

Depending on the degree of hardness of the tap water, the Distillation Apparatus must be cleaned regularly of scale for-

mations. First remove the outer and the left-hand inner lids (L), then unscrew the deflector and remove it, too. A suitable

descaling agent is a mixture of 10 % formic acid, 10 % acetic acid and 80 % distilled water. Fill the solvent into the boiler

until it covers the topmost scale deposits and heat up to maximum approx. 70 °C. Make absolutely certain not to bring the

mixture to a boil. In order to do so, close the hand-stop valve of the water mains supply ⑤ and switch on the Distillation

Apparatus until the temperature is reached. After approx. 30 minutes drain the solvent and scale mixture through the

drain cock "drain boiler" ② and rinse the boiler thoroughly with water several times.

Commercial descaling agents, suitable for use with stainless steel, can also be used according to the manufacturer's in-

structions (e.g. rea-calc® of M/s CHEMOTEC GmbH, 63486 Bruchköbel, Germany). Never use any products con-

taining hydrochloric acid! These will lead to damages to heating element, boiler, temperature sensor and the ducts of the

screw connections. Restart the unit as described in chapter 7 Initiation.

After descalings, the first few litres of distillate should not be used as it might contain traces of evaporated descaling agent.

Discard the first two to three complete fillings of distilled water in the storage tank.

Pilot Lamp Clean

9.2

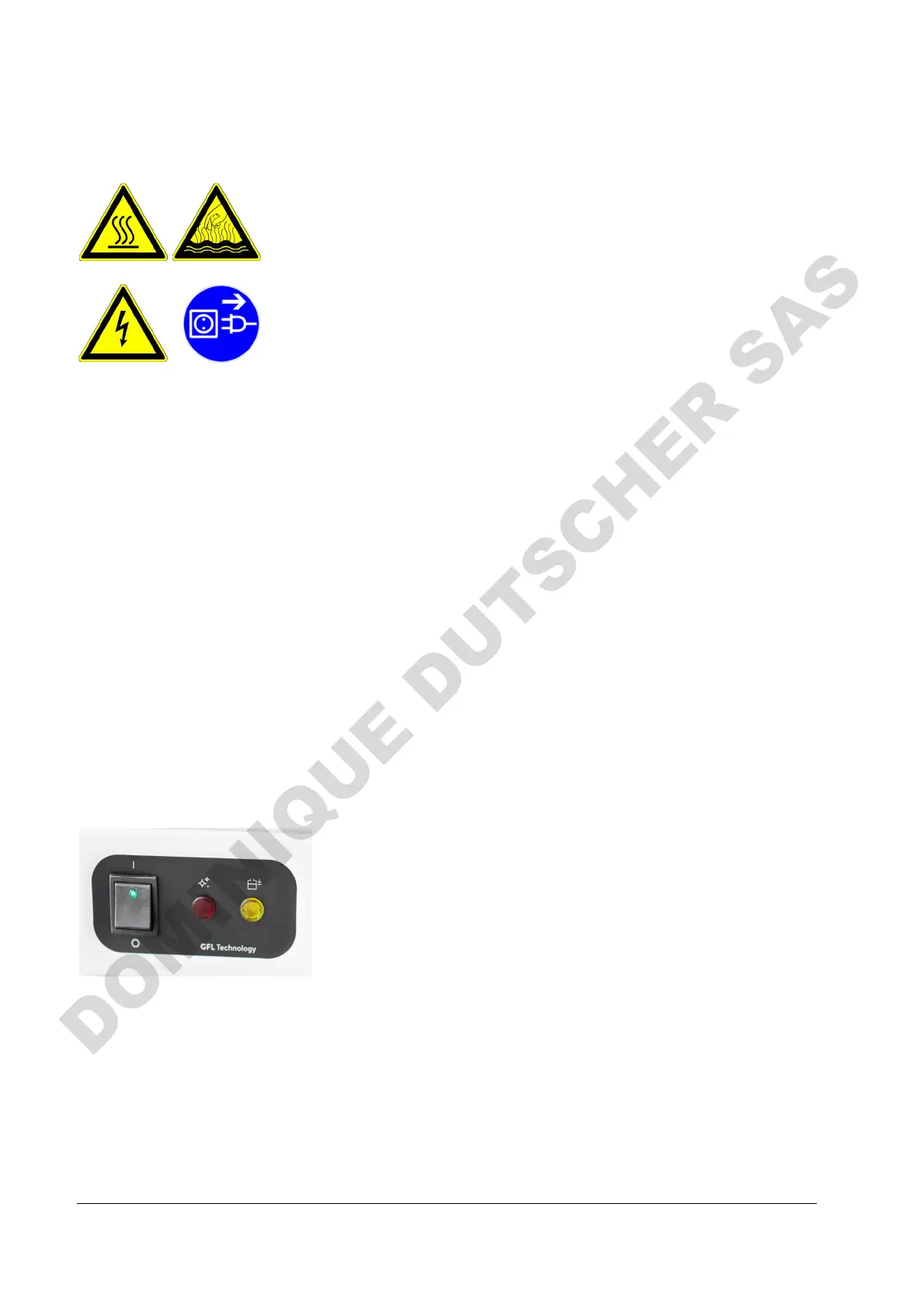

9.2.1 Foam formation caused by polluted water in the boiler

Depending on the degree of impurities in the feed water as well as on the grow-

ing contamination of the water in the boiler, caused by the distillation process,

the boiling water will foam up. Once the foam gets in contact with the electrode

in the boiler (L), an electronic impurity detector will switch off the unit, and the

red pilot lamp Clean (II) will light up.

The boiler must now be emptied through the drain cock "drain boiler" ② and be

rinsed several times with clean water..

I II

The operational interruption "Clean" is reset by switching the unit's main switch off and then on again. The subsequent re-

initiation is to be carried out as described in chapter 7.

The "Cleaning" function's purpose is to exchange polluted water in the boiler against clean water.

Loading...

Loading...